Method for preparing platinum-carbon catalyst

A platinum-carbon catalyst, platinum compound technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Short service life and other problems, to achieve the effect of long service life, high catalytic activity, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

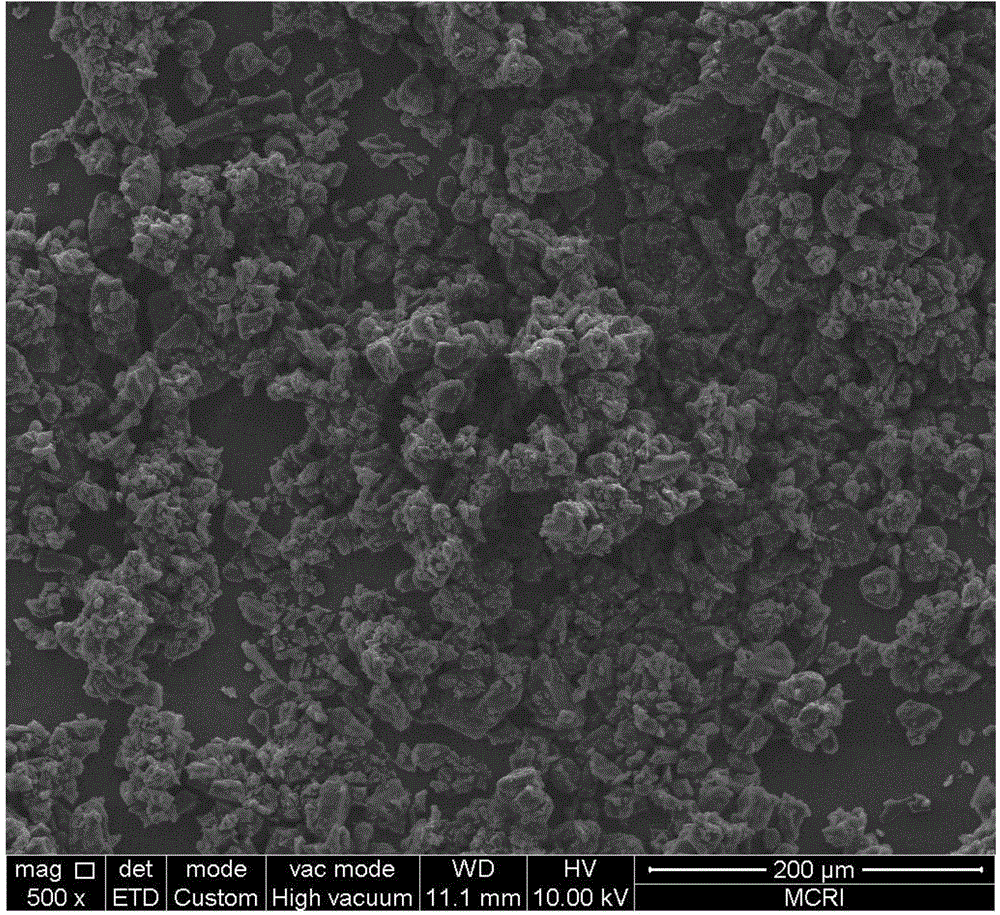

Image

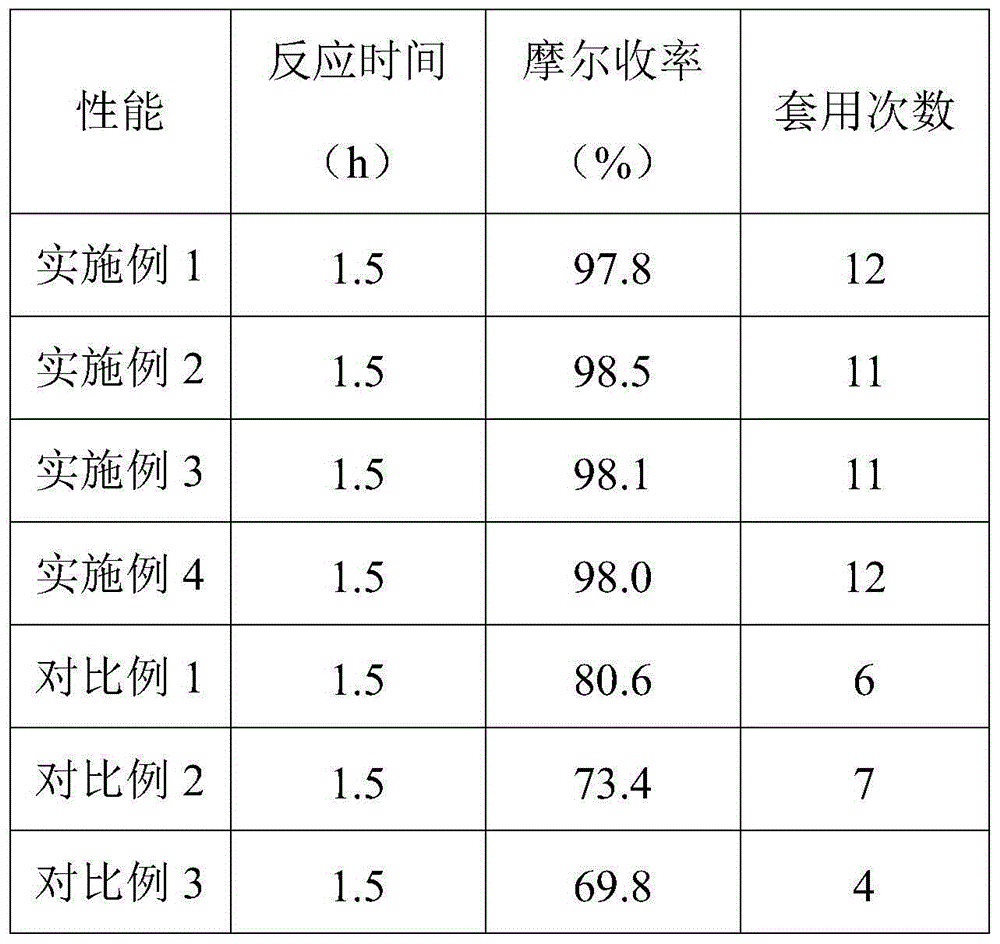

Examples

preparation example Construction

[0023] A kind of preparation method of platinum carbon catalyst of the present invention comprises the following steps:

[0024] Step 1: Modification of activated carbon support:

[0025] 1.1, the particle size is 200-300 mesh, the specific surface area is 800-1200m 2 / g, the activated carbon whose average pore radius is greater than 1.5nm is refluxed with a nitric acid solution with a concentration of 1%-10% for 1h-3h, and then the activated carbon after the reflux treatment is washed with deionized water until the pH of the washing liquid is 6-7, and dried , to obtain pretreated activated carbon carrier;

[0026] 1.2. Soak the pretreated activated carbon carrier in an aqueous surfactant solution with a concentration of 0.1-1.0%, stir for 1-3 hours to make it mix evenly and reach adsorption equilibrium, and obtain a modified activated carbon suspension;

[0027] Step 2: Preparation of platinum precursor solution:

[0028] Weigh the platinum-containing compound, add deioniz...

Embodiment 1

[0037] The particle size is 200 mesh, the specific surface area is 800m 2 / g, the activated carbon with an average pore radius of 2nm is placed in a boiling mass concentration of 1% nitric acid solution for reflux treatment for 1h, then the activated carbon after the reflux treatment is washed with deionized water until the pH of the washing solution is 7, and dried to obtain pretreatment The activated carbon carrier; soak the pretreated activated carbon carrier in a stearic acid aqueous solution with a mass concentration of 0.1%, stir for 3 hours to make it mix evenly and reach adsorption equilibrium, and obtain the modified activated carbon suspension;

[0038] Weigh platinum nitrate, add deionized water to dilute to a platinum concentration of 5g / L, and adjust the pH to 3 with hydrochloric acid under stirring to obtain a platinum precursor solution; the platinum precursor solution is added to the modified In the activated carbon suspension, mixed solution A is obtained;

...

Embodiment 2

[0041] The particle size is 300 mesh, the specific surface area is 1200m 2 / g, the activated carbon with an average pore radius of 2.5nm is placed in a boiling mass concentration of 4% nitric acid solution for reflux treatment for 2h, then the activated carbon after the reflux treatment is washed with deionized water until the pH of the washing solution is 6, dried, and obtained Treated activated carbon carrier; soak the pretreated activated carbon carrier in a 0.3% sodium dodecylbenzenesulfonate aqueous solution, stir for 1 hour to make it mix evenly and reach adsorption equilibrium, and obtain the modified activated carbon suspension ;

[0042] Weigh platinum citrate, add deionized water to dilute to a platinum concentration of 10g / L, and under stirring, adjust the pH to 1 with hydrochloric acid to obtain a platinum precursor solution; the platinum precursor solution is added to the modified In the active carbon suspension, mixed solution A is obtained;

[0043]Add KOH to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average hole radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com