Method and device for preparing thin film materials by spin-coating method

A thin-film material and spin-coating technology, which is applied to devices and coatings for coating liquid on the surface, can solve the problems of glue liquid throwing out, reduced processing efficiency, and poor uniformity, and achieves improved thickness uniformity, The effect of improving utilization and improving liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

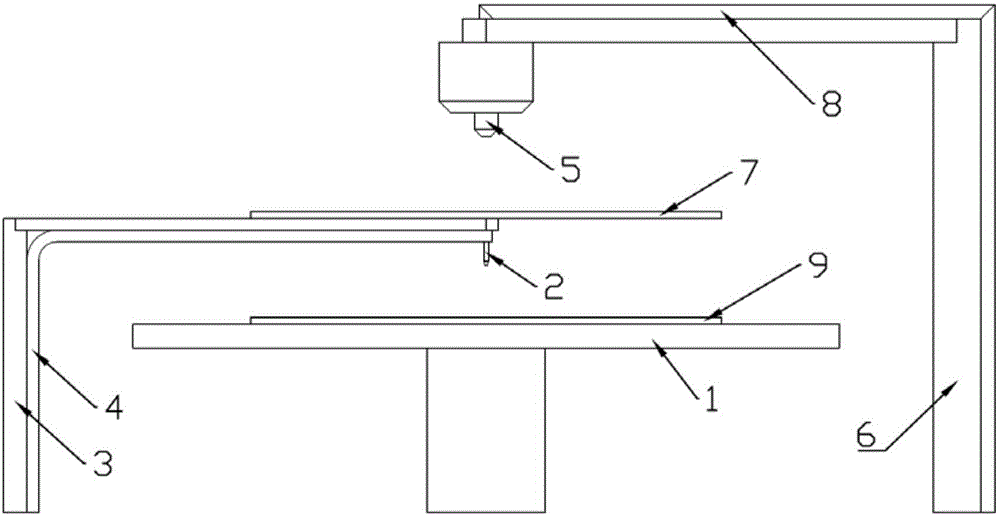

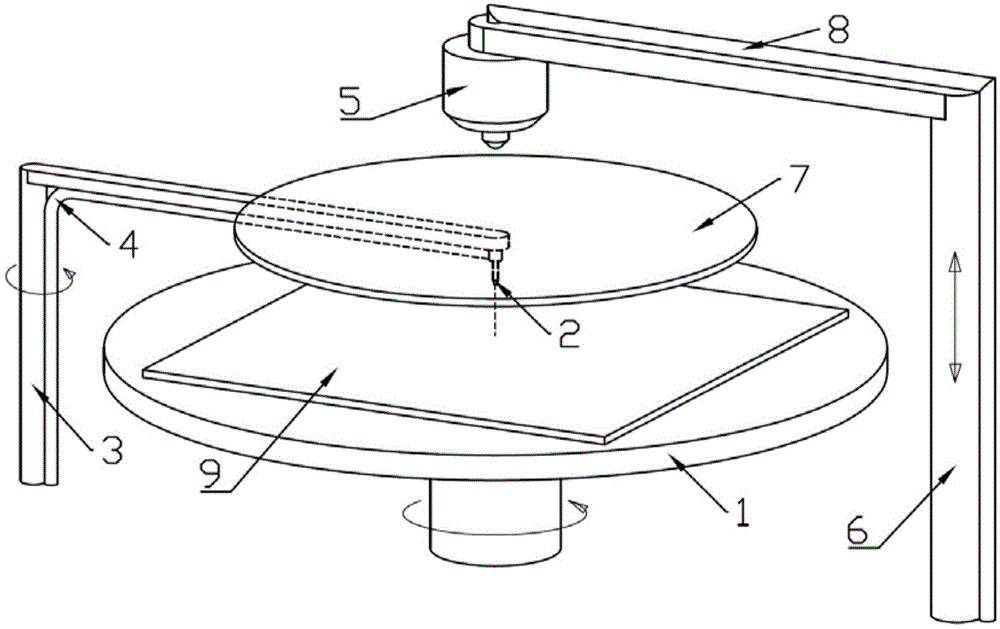

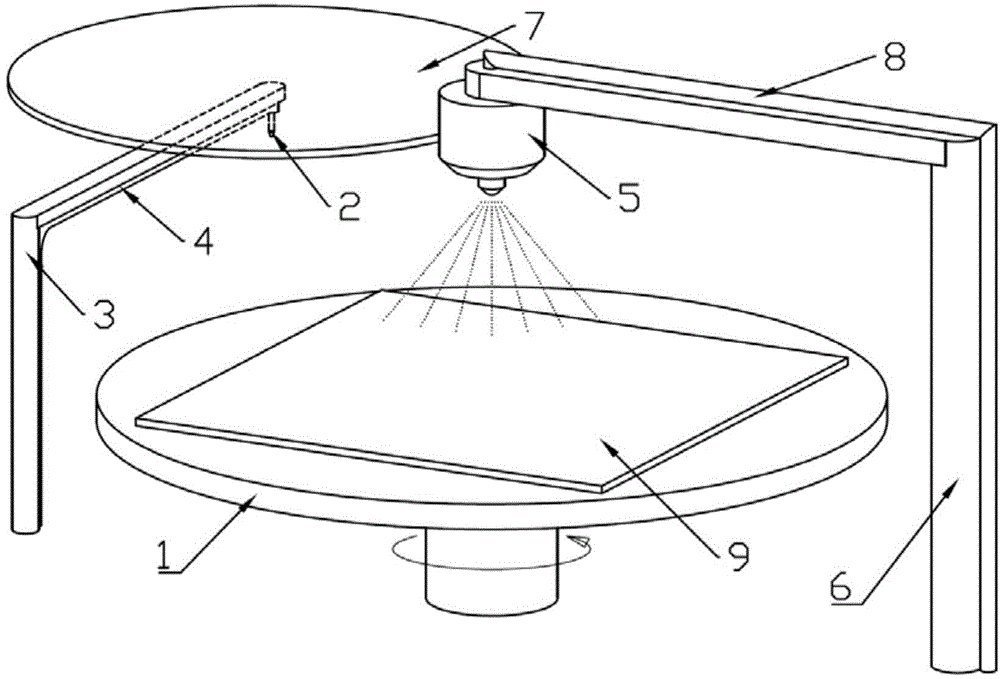

[0028] A kind of method utilizing spin-coating method to prepare film material, comprises the following steps:

[0029] 1) Spray the atomized glue evenly on the substrate, then drive the substrate to rotate so that the glue on the substrate forms a film layer, and stop the rotation of the substrate after the glue distribution is stable. On the surface of the substrate (glass or silicon wafer, etc.), a thin incubating layer that gradually becomes thicker from the center to the outside is formed, which plays a transitional role, allowing the surface of the substrate (such as glass) to form a layer of "fog", which is beneficial to the subsequent The diffusion of the spin coating solution, the stable distribution of the film layer, and the stable distribution time vary with the glue solution. The stable distribution means that the glue solution on the substrate completes the basic shape and no longer changes greatly with the rotation, that is, Because the dosage is very small and ...

no. 2 example

[0033] A kind of method utilizing spin-coating method to prepare film material, comprises the following steps:

[0034] 1) Inject glue at the center of the substrate, and then drive the substrate to rotate until the glue injected in the center is preliminarily shaped and then stops the rotation. The glue liquid completes the finalization of the basic center-to-outward gradually thinning distribution on the substrate, no large changes will occur with the rotation, and the rotation can be stopped at this time.

[0035] 2) Spray the atomized glue evenly on the substrate, then drive the substrate to rotate, and stop the rotation of the substrate after the glue distribution is stable.

[0036] First inject glue in the center and rotate it to form a film layer whose thickness gradually decreases from the center to the outside, and then spray the glue again by spraying method, and the thickness of the film layer formed after the sprayed glue is spin-coated shows that it gradually bec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com