Plastic bottle recycling and processing method and plastic bottle recycling and processing production line

A processing method and technology for plastic bottles, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of low plastic recycling quality, low production efficiency, poor processing equipment, etc. The effect of removing impurities and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with specific embodiment:

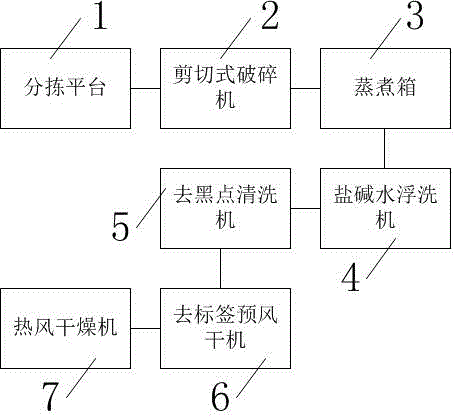

[0022] Plastic bottle recovery processing method of the present invention, comprises the steps:

[0023] a. Sorting, sorting plastic bottles according to color and removing plastic bottles with metal or sand. Use manual sorting or machine sorting. According to the needs of manufacturers, single-color plastic bottles are selected for easy storage and sale; plastic bottles with hard objects such as metal or sand are removed to avoid damage to the machine and reduce impurities.

[0024] b. Crushing, the sorted plastic bottles are sheared and broken to obtain plastic bottle flakes. The size of the plastic bottle after being sheared and broken is 8 mm to 14 mm. Compared with the traditional straight-cut crushing method, the shear crushing method is a progressive crushing method with less resistance, less vibration, less noise and faster shearing speed, which can increase the serv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com