Cyclohexanone preparation method and method for preparing oxime through cyclohexanone ammoximation reaction

A technology of cyclohexanone and cyclohexane, applied in the field of preparation of cyclohexanone, can solve the problems of low cyclohexanone conversion rate of cyclohexanone, low selectivity of cyclohexanone, poor treatment effect, complicated process flow, etc. The effect of high conversion rate and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

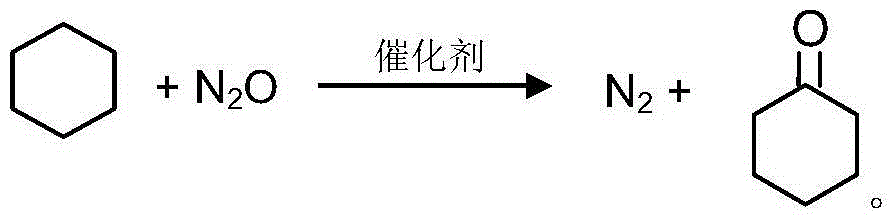

[0012] The invention provides a method for preparing cyclohexanone, wherein the method comprises: contacting dinitrogen monoxide and cyclohexane with a catalyst.

[0013] General reaction formula of the present invention is:

[0014]

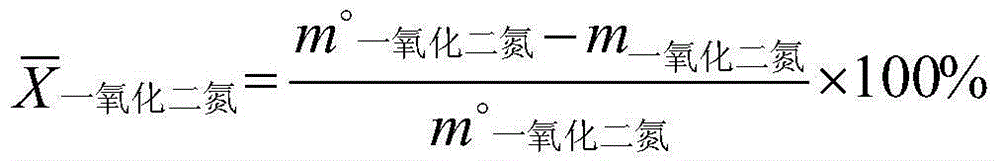

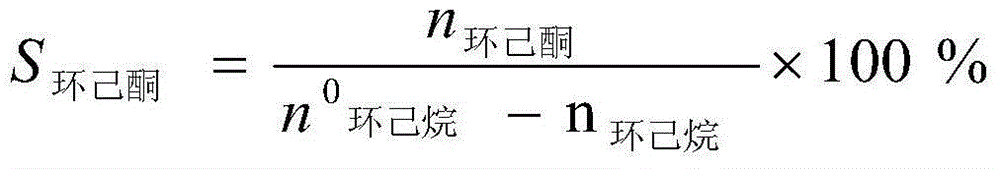

[0015] According to the method of the present invention, the molar ratio of nitrous oxide to cyclohexane may be 1:2-12. The inventors of the present invention have found that the conversion rate of dinitrogen monoxide and the selectivity of cyclohexanone all increase with the increase of the molar ratio of cyclohexane and dinitrogen monoxide in the raw material, but when the cyclohexane and dinitrogen monoxide When the molar ratio of nitrogen is greater than 6:1, the conversion rate of nitrous oxide does not increase significantly, therefore, preferably, the molar ratio of nitrous oxide to cyclohexane is 1:4-6.

[0016] According to the method of the present invention, the contacting of the nitrous oxide and cyclohexane with the catalyst is ...

Embodiment 1

[0055] This example is used to illustrate the preparation method of cyclohexanone provided by the present invention.

[0056] Helium, nitrous oxide and cyclohexane were added to the Fe-ZSM-5 catalyst in a molar ratio of 9:1:6 (the weight ratio of iron to ZSM-5 molecular sieve was 1:200, SiO 2 / Al 2 o 3 The molar ratio is 500, the particle size of the molecular sieve is 20 mesh) in the fixed fluidized bed reactor, the reaction temperature is controlled at 400°C, the pressure is controlled at normal pressure, and the total volume space velocity of the feed is 7000h -1 .

Embodiment 2

[0058] This example is used to illustrate the preparation method of cyclohexanone provided by the present invention.

[0059] Helium, nitrous oxide and cyclohexane were added to the Fe-ZSM-5 catalyst with a molar ratio of 9:1:5 (the weight ratio of iron to ZSM-5 molecular sieve was 1:200, SiO 2 / Al 2 o 3 The molar ratio is 500, the particle size of the molecular sieve is 20 mesh) in the fixed fluidized bed reactor, the reaction temperature is controlled at 430°C, the pressure is controlled at normal pressure, and the total volume space velocity of the feed is 5000h -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com