Nano-photocatalytic composite haze and formaldehyde removal latex paint and preparation method thereof

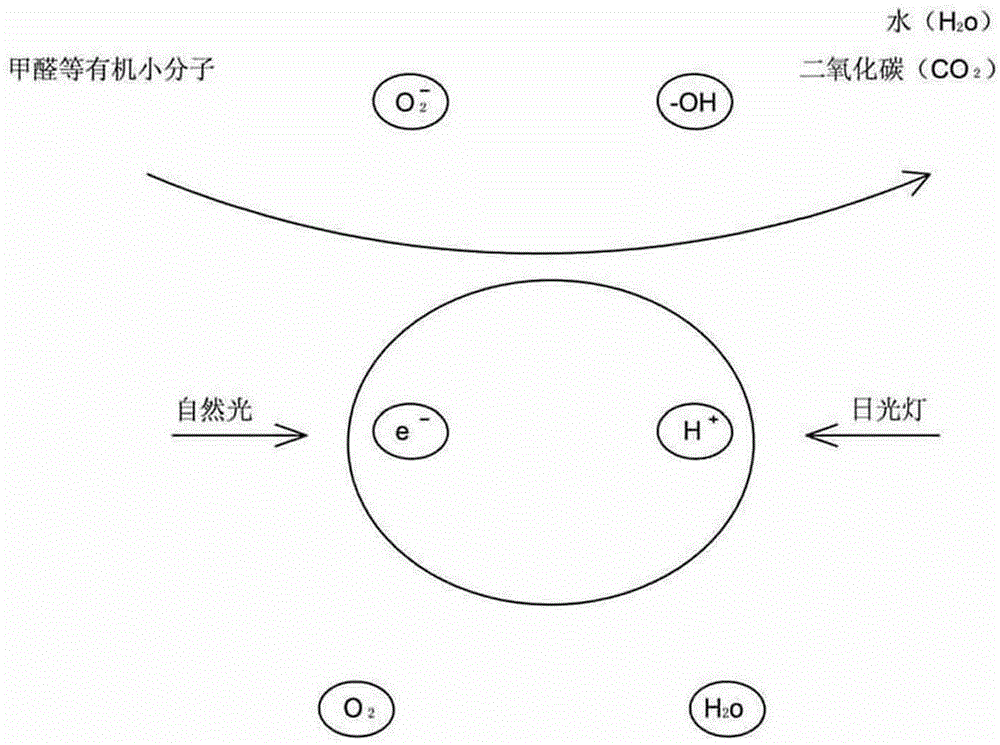

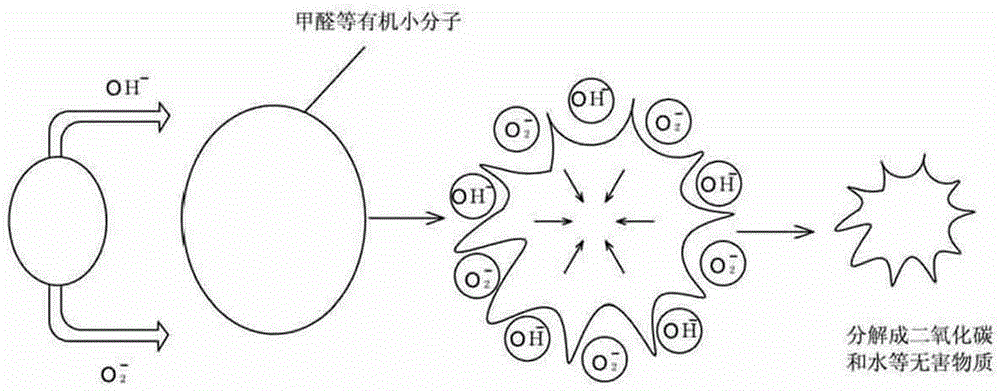

A kind of latex paint and composite technology, applied in latex paint, coating, etc., can solve the problems of poor formaldehyde removal effect, deterioration of indoor air quality, immature technology, etc., achieve long-term effective removal of formaldehyde and purify air, suitable for large The effect of mass production requirements and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

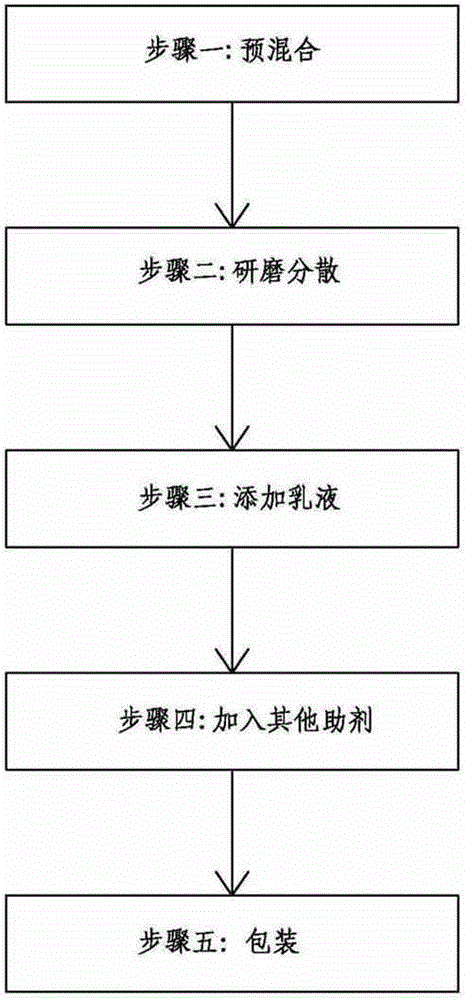

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in further detail below in conjunction with specific embodiment:

[0040] A kind of nano photocatalysis type haze-removing aldehyde-removing latex paint is characterized in that it comprises the following components and their weight percentages:

[0041] Water: 20-25%;

[0042] Polymer dispersant: 1.5-2%;

[0043] Multifunctional additives: 2-2.5%;

[0044] Nano-photocatalytic carbon-silicon composite raw material: 25%-35%;

[0045] Pigment and filler: 15-20%;

[0046] Emulsion: 20-30%;

[0047] Coalescing aids: 1-2%.

[0048] As a more specific embodiment: the above-mentioned nano-photocatalytic inorganic raw material is nano-Tio2, and its optimum weight percentage is between 25-35%;

[0049] The pigments and fillers include one or more of the following ingredients: rutile titanium dioxide, heavy calcium and talc; for example: the pigment is rutile titanium dioxide, the filler is composed of heavy calcium and talc, and the wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com