Sieving precipitation method for hydrogen sulfide gas in sulfur-containing drilling fluid

A technology of hydrogen sulfide and drilling fluid, which is applied in the field of oil drilling, can solve the problems of human safety and inapplicability that are easy to endanger the operator, and achieve the effects of reducing poisoning incidents, improving efficiency, and stabilizing nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

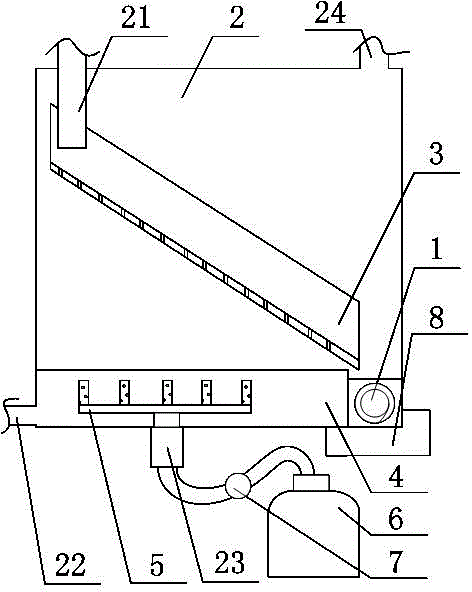

[0030] The method for sieving and separating out hydrogen sulfide gas in the sulfur-containing drilling fluid comprises the following steps:

[0031] (1) The mud enters the airtight box through the feed port, and the mud is screened into recycled slurry and waste particles through the screen in the airtight box; the sieved recycled slurry flows into the collection tank, and the granular waste passes through the spiral chip conveyor out of the closed box;

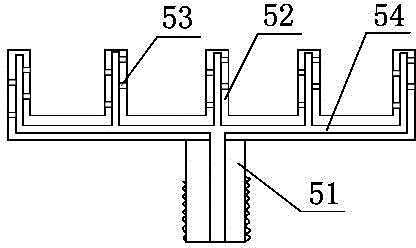

[0032] (2) Stir the recovered slurry flowing into the collection tank through the stirring device, and during the stirring process, transport the gas to the collection tank through the ventilation channel on the stirring device; the gas charged will recover the hydrogen sulfide gas in the slurry Replaced, the gas mixed with hydrogen sulfide flows out through the outlet pipe at the top of the airtight box;

[0033] (3) The hydrogen sulfide gas in the outflow gas is removed and discharged into the atmosphere or returned to th...

Embodiment 2

[0041] The difference between this embodiment and Embodiment 1 is that the gas charged in the step (2) in this embodiment is an inert gas. At this time, the effluent gas returns to the collection pool after removing the hydrogen sulfide gas.

[0042] Through the above arrangement, the inert gas can be effectively recycled, thereby saving costs, and effectively preventing the operator from contacting the gas, making the operation safer.

Embodiment 3

[0044] The difference between this embodiment and embodiment 1 or 2 is that a gas storage tank is connected to the ventilation channel, and the gas delivered to the collection pool in step (2) is taken from the gas storage tank. The gas in the gas storage tank is delivered to the collection pool through the delivery pump and the check valve.

[0045] Through the setting of the gas storage tank, delivery pump and check valve, it is possible to effectively prevent the gas in the gas storage tank from being well filled into the collection pool due to the high air pressure in the airtight box.

[0046] In order to compare the desulfurization effect of the present invention, the present invention provides a control group, and its specific operation steps are as follows: on the basis of Example 1, the step of stirring the recovered slurry in the collection tank by the stirring device is removed, and simultaneously No inert gas is introduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com