Solidified body used for performing glass curing process on low-medium radioactive waste and method

A technology of glass solidification and solidification, used in radioactive purification, nuclear engineering and other directions, can solve the problems of large material and energy consumption, low leaching rate, complex solidification process, etc., to achieve easy engineering application, low melting temperature, Economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

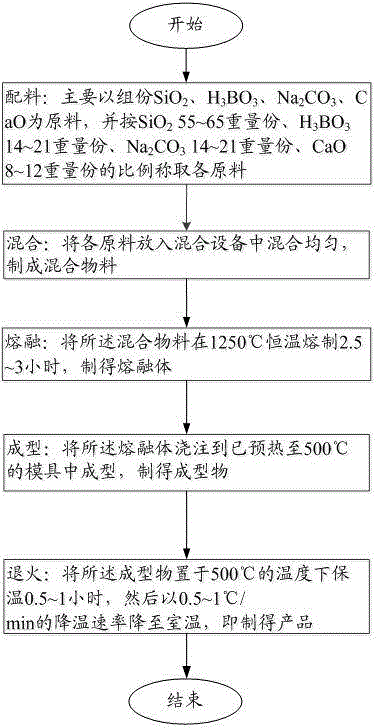

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0028] like figure 1 As shown, it is a method for preparing a cured body for vitrification treatment of low and intermediate level waste provided by Embodiment 1 of the present invention, the method comprising:

[0029] a. Ingredients: mainly composed of SiO 2 、H 3 BO 3 、Na 2 CO 3 , CaO as raw material, and according to SiO 2 55~65 parts by weight, H 3 BO 3 14~21 parts by weight, Na 2 CO 3 14-21 parts by weight, CaO 8-12 parts by weight, each raw material is weighed;

[0030] b. Mixing: Put all raw materials into mixing equipment (mortar or ball milling equipment) and mix them evenly to make mixed materials;

[0031] c. Melting: melt the mixed material at a constant temperature of 1250°C for 2.5~3 hours to obtain a melt;

[0032] d. Molding: pour th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com