Light emitting diode epitaxial wafer and preparation method thereof

A technology of light-emitting diodes and epitaxial wafers, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as failure of light-emitting diodes, and achieve the effects of improving crystal quality, reducing aggregation, and preventing failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

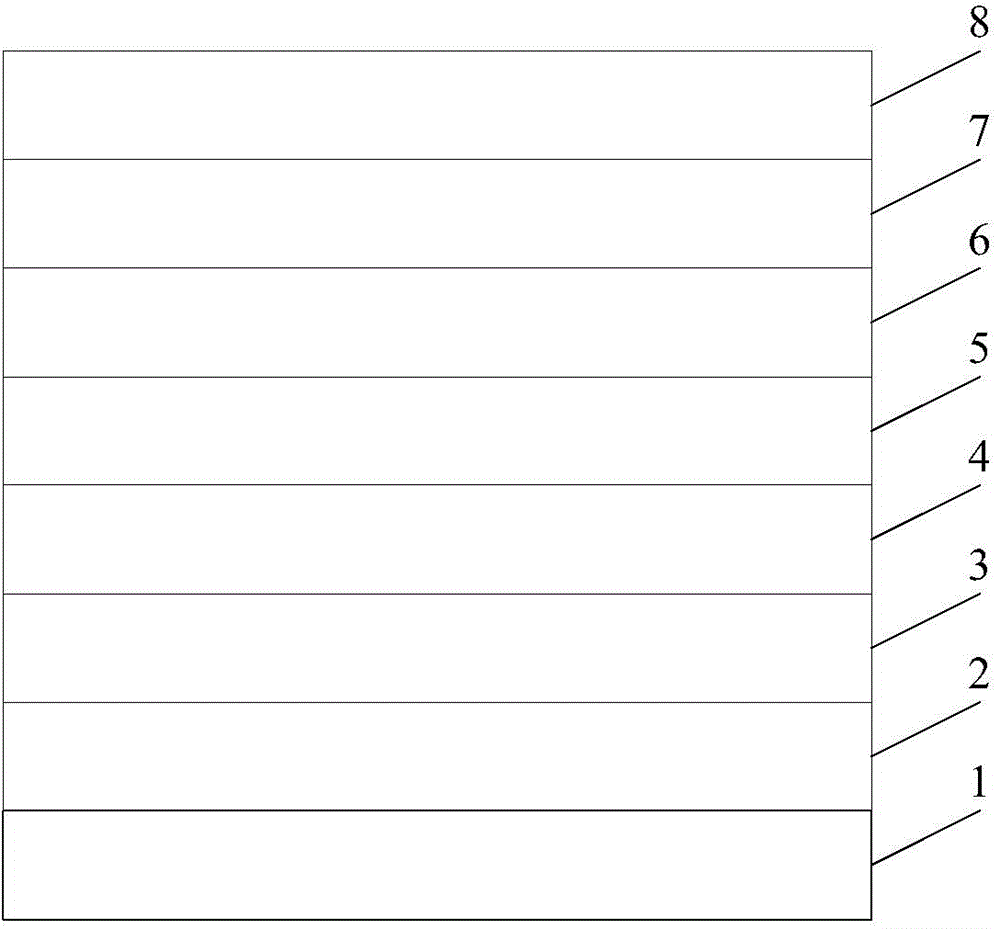

[0034] An embodiment of the present invention provides a light emitting diode epitaxial wafer, see figure 1 , the epitaxial wafer includes a substrate 1, and a buffer layer 2, an N-type layer 3, a stress release layer 4, a first current spreading layer 5, a multi-quantum well layer 6, and a second current spreading layer stacked on the substrate 1 in sequence. 7 and P-type layer 8.

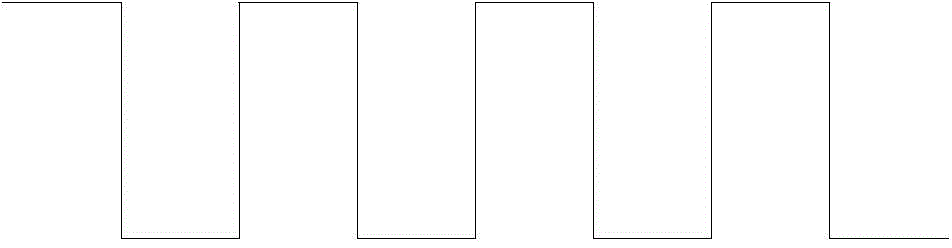

[0035] In this embodiment, the first current spreading layer 5 includes several alternately grown Al x Ga 1-x N layer 51 and In y Ga 1-y N layer 52, and Al in the first current spreading layer 5 x Ga 1-x N layer 51 and In y Ga 1-y The N layer 52 is all N-type doped. The second current spreading layer 7 includes several alternately grown Al x Ga 1-x N layer 71 and In y Ga 1-y N layer 72, and Al in the second current spreading layer 7 x Ga 1-x N layer 71 and In y Ga 1-y None of the N layers 72 are doped. Wherein, 0

[0036] In an implementation of this embodiment, the A...

Embodiment 2

[0098] The embodiment of the present invention provides a method for preparing a light-emitting diode epitaxial wafer, see Figure 4 , the preparation method comprises:

[0099] Step 201: growing a buffer layer on a substrate.

[0100] In practical application, the Metal-Organic Chemical Vapor Deposition (MOCVD) method is adopted, trimethyl (or triethyl) gallium is used as gallium source, high-purity NH3 is used as nitrogen source, trimethyl Indium is used as an indium source, trimethylaluminum is used as an aluminum source, silane is used for N-type doping, and magnesiumocene is used for P-type doping.

[0101] Specifically, the substrate may be a sapphire substrate.

[0102] Specifically, the buffer layer may include a low-temperature buffer layer, a three-dimensional 3D layer, a merged layer, and a high-temperature buffer layer. The low-temperature buffer layer, three-dimensional 3D layer, merged layer, and high-temperature buffer layer are all GaN layers. The growth tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com