Preparation method for health care sugar-free natural product powder

A technology of natural products and health powders, applied in the biological field, can solve problems such as unfavorable consumption, and achieve the effect of advanced design and unique production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

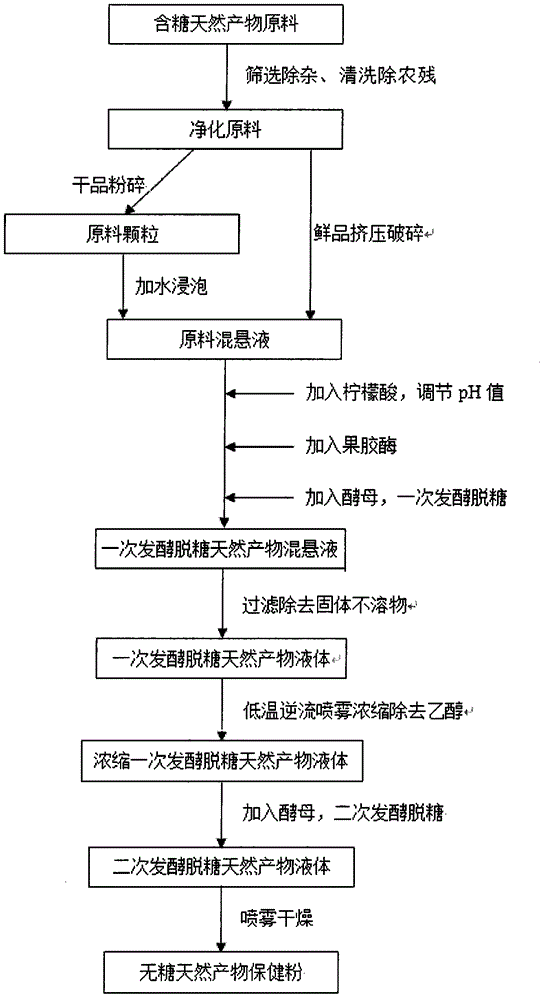

[0020] Such as figure 1 As shown, the embodiment of the present invention provides a method for preparing sugar-free natural product health-care powder, which includes the following steps:

[0021] S1. Screen the raw materials of sugar-containing natural products, after removing rotten fruits and impurities, washing and removing pesticide residues, to obtain purified raw materials;

[0022] S2, crushing or crushing the purified raw material obtained in step S1 (crushing the dry product to granular shape, and crushing the fresh product with high water content), adding an appropriate amount of water to obtain a raw material suspension;

[0023] S3. Add citric acid to the raw material suspension obtained in step S2, adjust the pH to 3.3, add pectinase at a ratio of 70 mg / L, mix well, and then add Angel SY yeast at a ratio of 200 mg / L, and mix Homogeneous, get a mixture;

[0024] S4. Put the mixture obtained in step S3 at a temperature of 25°C, ferment for 7-9 days, and take samples ever...

Embodiment 1

[0031] Take 50kg of raw mulberry fruits, screen and wash to obtain mulberry pure fruits. It is crushed to obtain mulberry pulp. First add citric acid to the mulberry pulp, adjust the pH of the pulp to 3.3, then add pectinase to the pulp at 70mg / L, mix well, and finally add Angel SY yeast to the pulp at 200mg / L, mix Evenly. The fermentation temperature of the mixed fruit pulp was controlled at 25°C, and samples were taken every 24 hours to determine the residual sugar content in the fermented fruit pulp. After 8 days, the residual sugar content was less than 0.5%, that is, the first fermentation and desugarization was completed. After the first fermentation and desugarization, filter to separate the fermented fruit pulp from solid and liquid, remove the solid residue, and retain the liquid part. The fermentation broth is subjected to low-temperature countercurrent spray concentration until the ethanol content in the concentrated solution is lower than 4° (v / v), and the volume ...

Embodiment 2

[0033] Take 50kg of raw mulberry fruits, screen and wash to obtain mulberry pure fruits. It is crushed to obtain mulberry pulp. First add citric acid to the mulberry pulp, adjust the pH of the pulp to 3.3, then add pectinase to the pulp at 70mg / L, mix well, and finally add Angel SY yeast to the pulp at 200mg / L, mix Evenly. The fermentation temperature of the mixed fruit pulp is controlled at 25°C, and samples are taken every 24 hours to determine the residual sugar content in the fermented fruit pulp. After 7 days, the residual sugar content is less than 0.5%, that is, the first fermentation and desugarization ends. After the first fermentation and desugarization, filter to separate the fermented fruit pulp from solid and liquid, remove the solid residue, and retain the liquid part. The fermentation broth is subjected to low-temperature countercurrent spray concentration until the ethanol content in the concentrated solution is lower than 4° (v / v), and the volume of the ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com