Spiral type gas-liquid separator under micro-gravity based on porous material

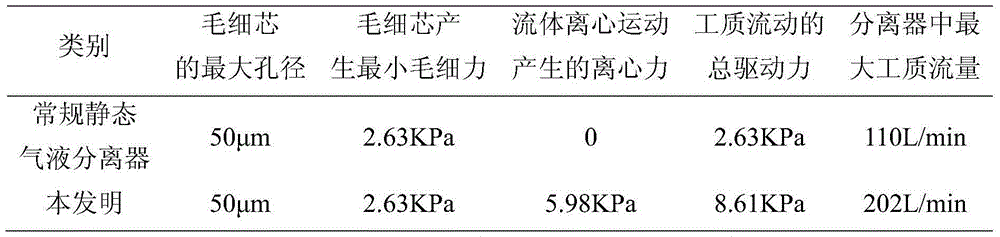

A technology of gas-liquid separator and porous material, which is applied in the field of spiral gas-liquid separator under microgravity, which can solve the problems of insufficient capillary force of the grid inside the wall and limitation of separation volume of the separator, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In order to reduce the pressure of logistics support in space missions, the CO in the spacecraft 2 and H 2 The treatment and recovery of O and other substances mainly rely on the regeneration of the annular space and the life support system, and the gas-liquid separation process is a key link in the system. This example illustrates the application of a porous material-based spiral gas-liquid under microgravity in the regenerative annular space and life support system proposed by the present invention. Set the reclaimed substance to be liquid water, the selection of the porous wall material in this embodiment is a hydrophilic material (such as polyacrylonitrile material, polysulfone material, etc.), and the capillary core of the center is selected as a hydrophobic material (such as polytetrafluoroethylene vinyl, etc.). The liquid phase outlet 10 of the separator is arranged at the bottom center of the housing 3, so the density distribution of the porous material on the...

Embodiment 2

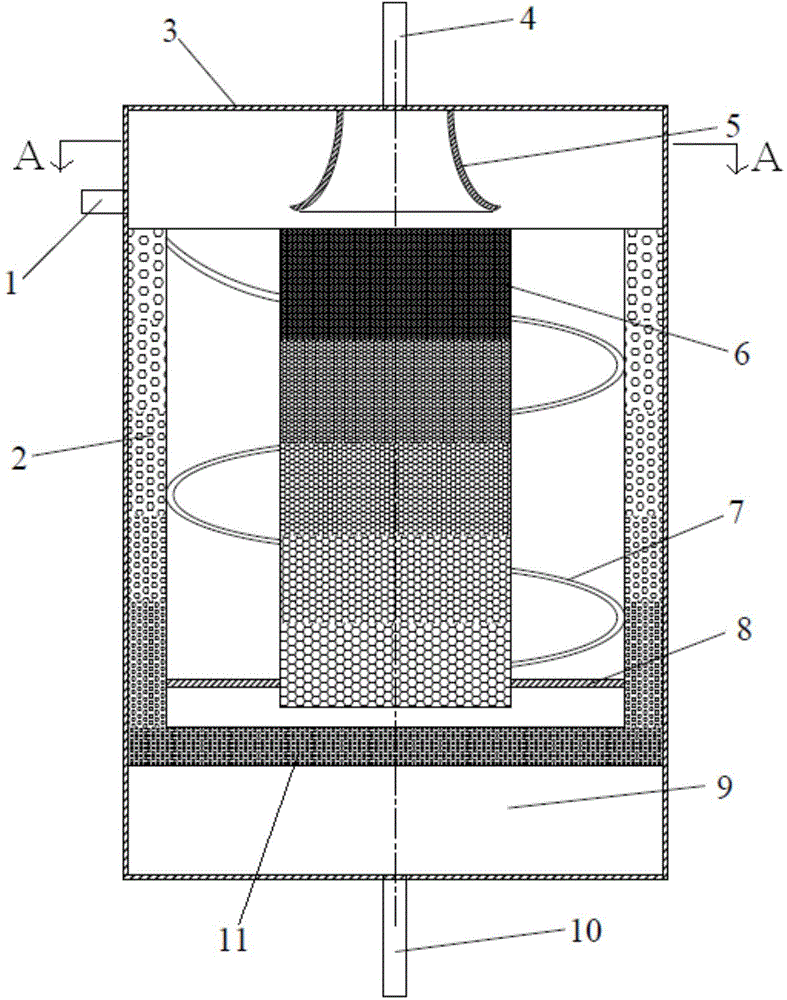

[0045] This example illustrates the application of a microgravity spiral gas-liquid separator based on porous materials proposed by the present invention in a vapor compression system. The working fluid used in this example is set to be R134a, the porous material on the tube wall is selected as a material that R134a can wet well, and the capillary core in the center is selected as a material that R134a cannot wet well. The liquid phase outlet 10 of the separator is arranged at the center of the bottom, so the density distribution of the porous material on the wall is as attached. figure 1 shown.

[0046] After the R134a in the state of gas-liquid two-phase flow flows into the gas-liquid separator through the mixed fluid inlet 1, it makes a spiral movement in the separator under the action of the spiral baffle 7. Due to the difference in the density of R134a in the gas phase and R134a in the liquid phase, the R134a in the gas phase and the R134a in the liquid phase are distrib...

Embodiment 3

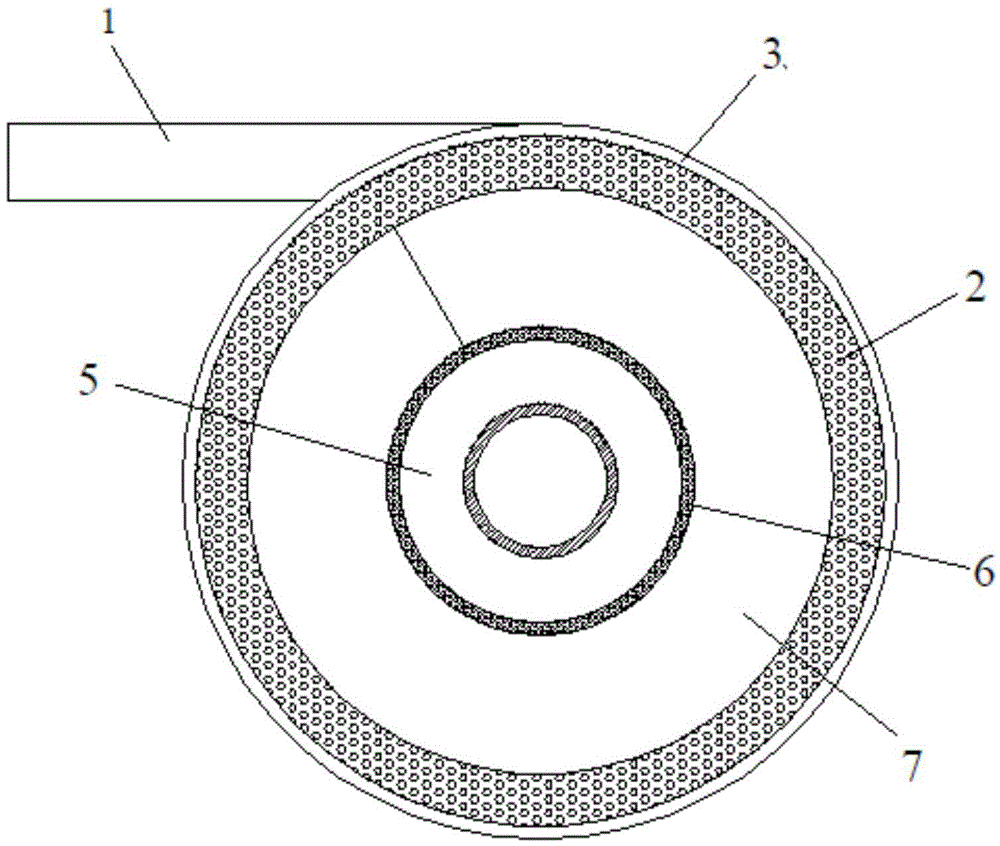

[0052] The oxygen currently used in spacecraft is regenerated by electrolysis of water. In order to obtain gaseous oxygen and recover excess water, H 2 O-O 2 the separation process. This example illustrates the application of a microgravity spiral gas-liquid separator based on porous materials proposed by the present invention in an electrolytic oxygen production system. In this example, the porous material of the wall is selected as a hydrophilic material, while the capillary core in the center is selected as a hydrophobic material. The liquid phase outlet of the separator is arranged at the center of the bottom, so the density distribution of the porous material on the wall is as follows: figure 2 shown.

[0053] H after pretreatment 2 O-O 2 The mixed fluid enters the gas-liquid separator along the tangential direction through the mixed fluid inlet. When passing through the helically arranged baffles, due to the centrifugal force, gaseous oxygen and oxygen bubbles are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com