Coking slop oil tank waste gas deodorization purifying device based on chemical absorption method

A chemical absorption and purification device technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as unsuitable treatment of hydrocarbon-containing sulfur-containing waste gas, unbalanced odor gas concentration, and potential safety hazards, etc. The effect of large operation flexibility, strong selectivity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

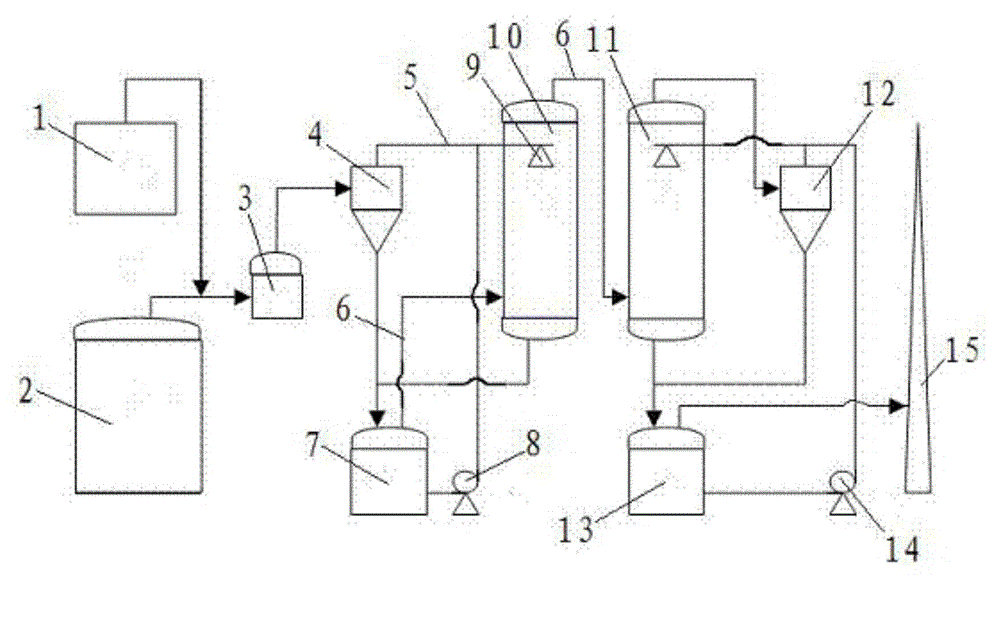

[0015] like figure 1 Shown, the present invention is realized in this way, and it comprises sewage pool 1, coking waste oil tank 2, buffer tank 3, first ejector 4, absorbent circulation pipe 5, air guide pipe 6, first circulation tank 7, pump Ⅰ8, spray head 9, first absorption tower 10, second absorption tower 11, second injector 12, second circulation tank 13, pump II 14 and exhaust pipe 15, the structural features are that the first absorption tower 10 and the second Absorption towers 11 have the same structure, and are equipped with spray heads 9 inside. The waste gas from the sewage tank 1 and the coking waste oil tank 2 is passed into the buffer tank 3 connected thereto. The buffer tank 3 is connected to the first injector 4, and The bottom of 4 is connected with the bottom of the first circulation tank 7 top and the first absorption tower 10 respectively, and the top of the first circulation tank 7 is connected on the side wall of the first absorption tower 10 below the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com