Catalyst carrier material, catalyst carrier and preparation method thereof

A catalyst carrier and carrier material technology, applied in catalyst carriers, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of uneven dispersion of alumina and activated carbon, unstable properties of amorphous alumina, and sludge impurities. High-level problems, to achieve high reactivity and use stability, improve activity and use stability, and make full use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

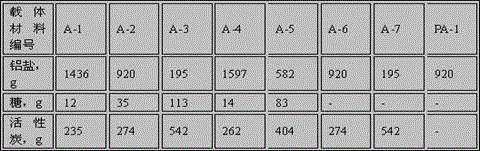

Embodiment 1

[0050] Solid aluminum chloride was added to distilled water while heating and stirring until dissolved to obtain solution (a). Add an appropriate amount of distilled water to the concentrated ammonia water and dilute it into about 10wt% dilute ammonia water (b). Add the powdered coconut shell charcoal to the glucose aqueous solution and mix evenly, the liquid-solid volume ratio is 3:1, then add water and make a slurry to obtain the slurry (c). After adding (a) into the gelling tank and stirring and heating to 60°C, open the valve of the container containing (b), and control the system in the tank to drop to pH=4.0 within 10 minutes, then add (c), continue to add (b) dropwise, and control the dropwise addition of the tank system to pH=8.0 within 30 minutes. Keep the temperature at 60°C, pH=8.0, age for 1 hour, filter the material in the tank, wash until there is no chloride ion, filter, dry the filter cake at 110°C for 10 hours to obtain carrier material A-1, and then Calcine...

Embodiment 2

[0053] Solid aluminum sulfate was added to distilled water while heating and stirring until dissolved to obtain solution (a). Add an appropriate amount of distilled water to the concentrated ammonia water and dilute it into about 10wt% dilute ammonia water (b). Add the powdered coconut shell charcoal to the glucose aqueous solution and mix evenly, the liquid-solid volume ratio is 5:1, then add water and make a slurry to obtain the activated carbon slurry (c). Take a plastic tank, add (a) into the tank, stir and heat to 60°C, open the valve of the container containing (b), control the system in the tank to drop to pH=4.0 within 10 minutes, open (c ) the valve of the container, continue to drop (b), control the dropwise addition of the system in the tank to pH=8.0 within 30 minutes, control the valve of the container of (c), and ensure that the drop is completed at this time. Keep the temperature at 60°C, pH=8.0, age for 1 hour, filter the material in the tank, wash until there...

Embodiment 3

[0056] Solid aluminum sulfate was added to distilled water while heating and stirring until dissolved to obtain solution (a). The solid sodium metaaluminate is formulated to a concentration of 250g Al 2 o 3 / L sodium aluminate solution (b). Add the powdered coconut shell charcoal into the sucrose aqueous solution and mix evenly, the liquid-solid volume ratio is 3:1, then add water and make a slurry to obtain the slurry (c). Take a glue tank, put 2L of deionized water into it, stir and heat it to 60°C, then add the slurry (c), open the valve of the container containing (a) and (b) at the same time, control the pH of the system to 8.0, and control it for 45 minutes After dripping (a) inside, close the valve. Keep the temperature at 60°C, pH=8.0, age for 1 hour, filter the material in the tank, wash until there is no sulfate ion, filter, and dry the filter cake at 110°C for 10 hours to obtain carrier material A-3. Then it was calcined at 550° C. for 5 hours under the protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com