A method for preparing palladium nanowires by utilizing the nuclear polyhedrin protein of cotton bollworm

A nuclear polyhedron and palladium nanowire technology is applied in the field of nanomaterial preparation, which can solve the problems of insufficient green economy and mild preparation conditions, and achieve the effects of cheap raw materials, uniform morphology and high utilization rate of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

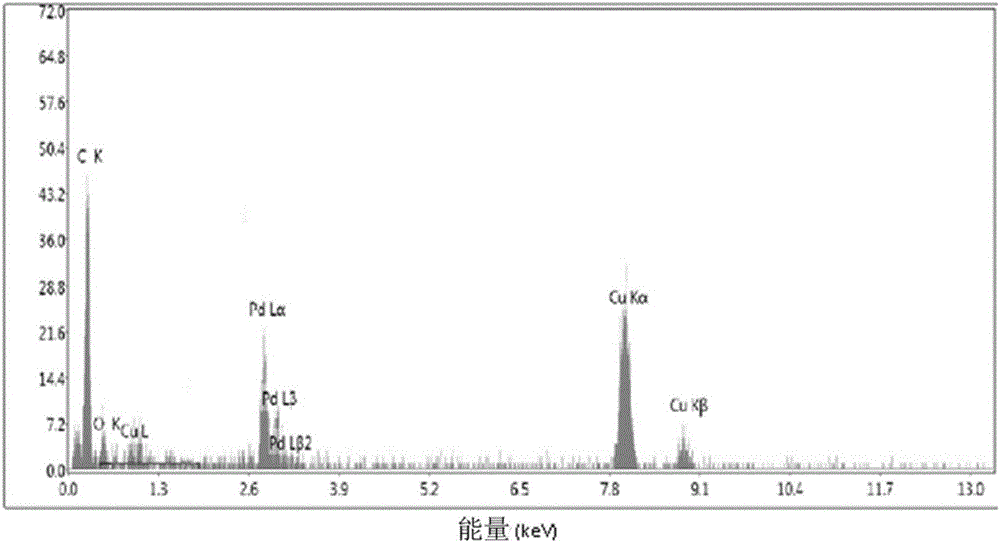

[0017] Prepare 10 mg / mL polyhedron suspension with ultrapure water, add 1 mL of alkaline hydrolysis solution for every 4 mL of polyhedron suspension, the alkaline hydrolysis solution is 0.3mol / L sodium carbonate, 0.5mol / L sodium chloride and 0.03mol / L The mixed solution of disodium ethylenediaminetetraacetate was allowed to stand for 30 minutes, and after centrifugation at 5000r / min for 5 minutes, the supernatant was sucked out, and every 5mL of the supernatant was put into an ultracentrifuge tube for ultracentrifugation. The resulting supernatant was adjusted to pH 5.8 with hydrochloric acid solution, and the polyhedron protein was precipitated out. After centrifuging at 4000r / min for 5min, the resulting precipitate was dried with a vacuum freezer (vacuum degree 80mT, -105°C) to obtain the polyhedron. protein powder.

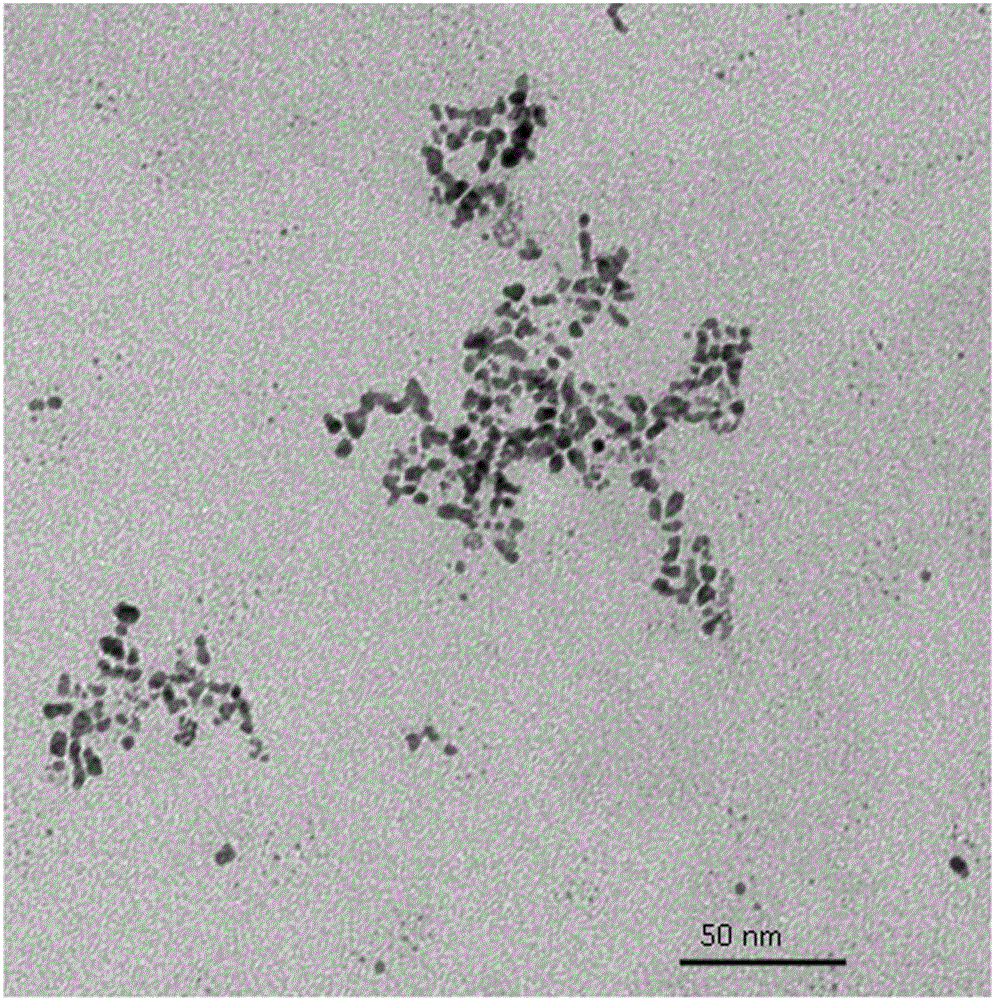

[0018] Take 300 μL of 0.03 mg / mL polyhedrin solution, add 100 μL of 2 mM Na 2 PdCl 4 solution, adjust the pH to 5 with sodium hydroxide, mix well and incubat...

Embodiment 2

[0021] Prepare 10mg / mL polyhedron suspension with ultrapure water, add 1mL of alkaline hydrolysis solution for every 5mL polyhedron suspension, the alkaline hydrolysis solution is 0.3mol / L sodium carbonate, 0.5mol / L sodium chloride and 0.03mol / L The mixed solution of disodium ethylenediaminetetraacetate was allowed to stand for 45 minutes, and after being centrifuged at 6000r / min for 7 minutes, the supernatant was sucked out, and every 4mL of the supernatant was put into an ultracentrifuge tube for ultracentrifugation, and the ultracentrifuged The resulting supernatant was adjusted to a pH of 5.8 with hydrochloric acid solution, and the polyhedron protein was precipitated out. After centrifuging at 3000r / min for 7 minutes, the resulting precipitate was dried with a vacuum freezer (vacuum degree 80mT, -105°C) to obtain the polyhedron. protein powder.

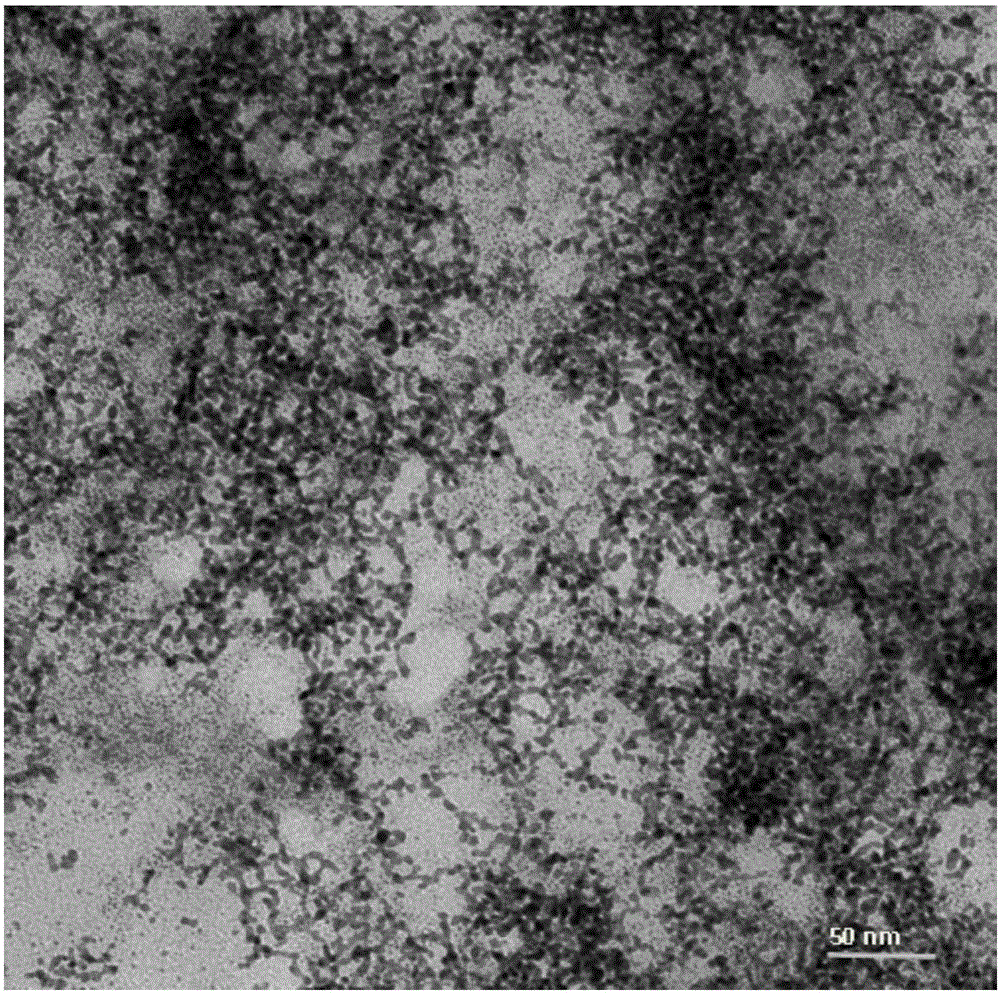

[0022] Take 300 μL of 0.03 mg / mL polyhedrin solution, add 150 μL of 10 mM Na 2 PdCl 4 solution, adjust the pH to 6 with sodiu...

Embodiment 3

[0025] Prepare 10mg / mL polyhedron suspension with ultrapure water, add 1mL of alkaline hydrolysis solution for every 8mL polyhedron suspension, the alkaline hydrolysis solution is 0.3mol / L sodium carbonate, 0.5mol / L sodium chloride and 0.03mol / L The mixed solution of disodium ethylenediaminetetraacetate was left to stand for 50min, centrifuged at 5500r / min for 10min, the supernatant was sucked out, and each 6mL supernatant was put into an ultracentrifuge tube for ultracentrifugation. The resulting supernatant was adjusted to a pH of 5.8 with hydrochloric acid solution, and the polyhedron protein precipitated out. After centrifuging at 3500r / min for 10min, the resulting precipitate was dried with a vacuum freezer (vacuum degree 80mT, -105°C) to obtain the polyhedron. protein powder.

[0026] Take 600 μL of 0.03 mg / mL polyhedrin solution, add 150 μL of 15 mM Na 2 PdCl 4 solution, adjust the pH to 7 with sodium hydroxide, mix well and incubate in an air-bath shaker at 30°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com