Grinding device with inverted V-shaped slot in grinding wheel and grinding method

A herringbone and grinding technology, which is applied in the direction of grinding/polishing safety devices, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of insufficient cooling of grinding fluid and surface quality, and achieve the elimination of cycle time High dynamic impact load, good stiffness and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

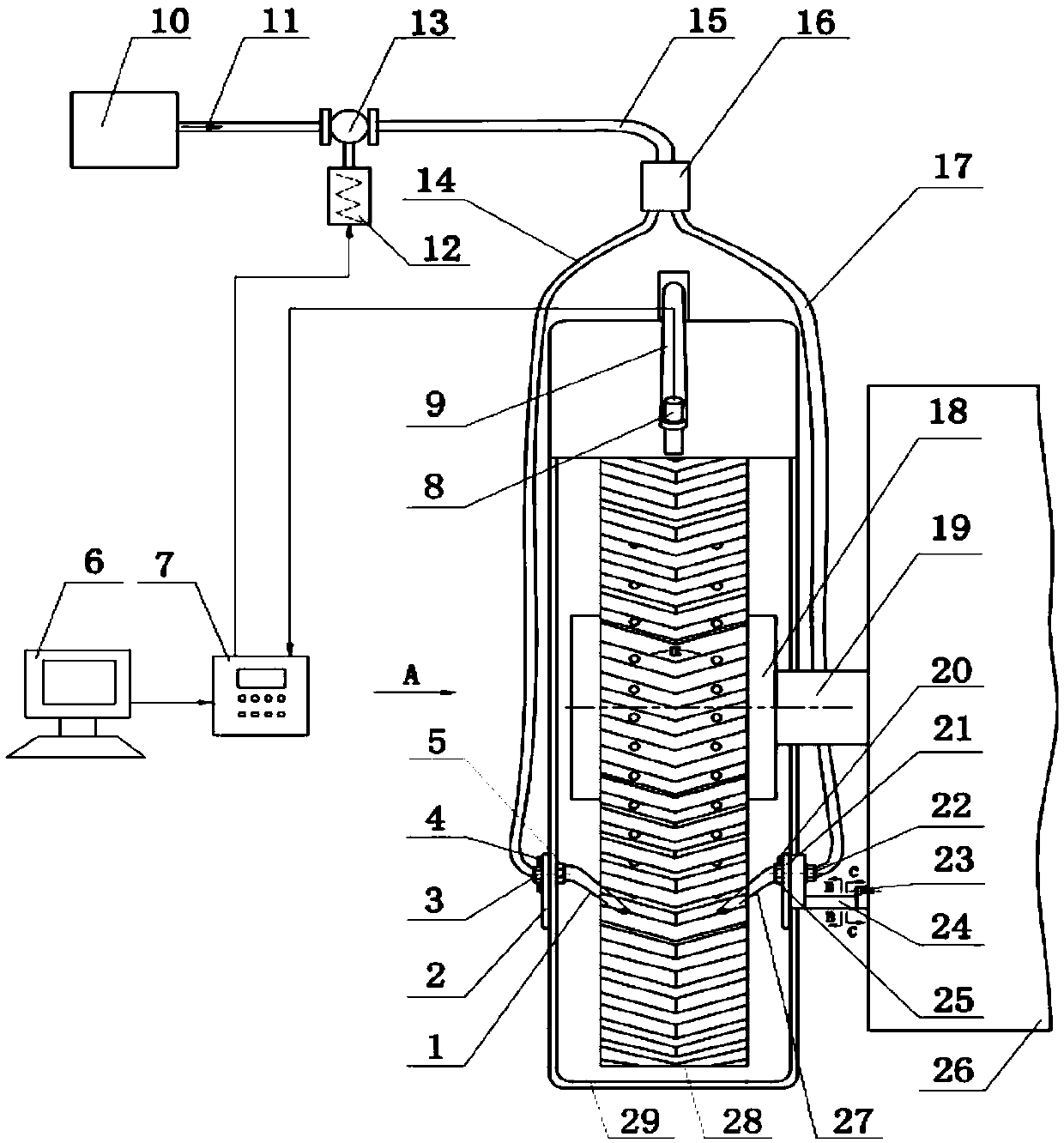

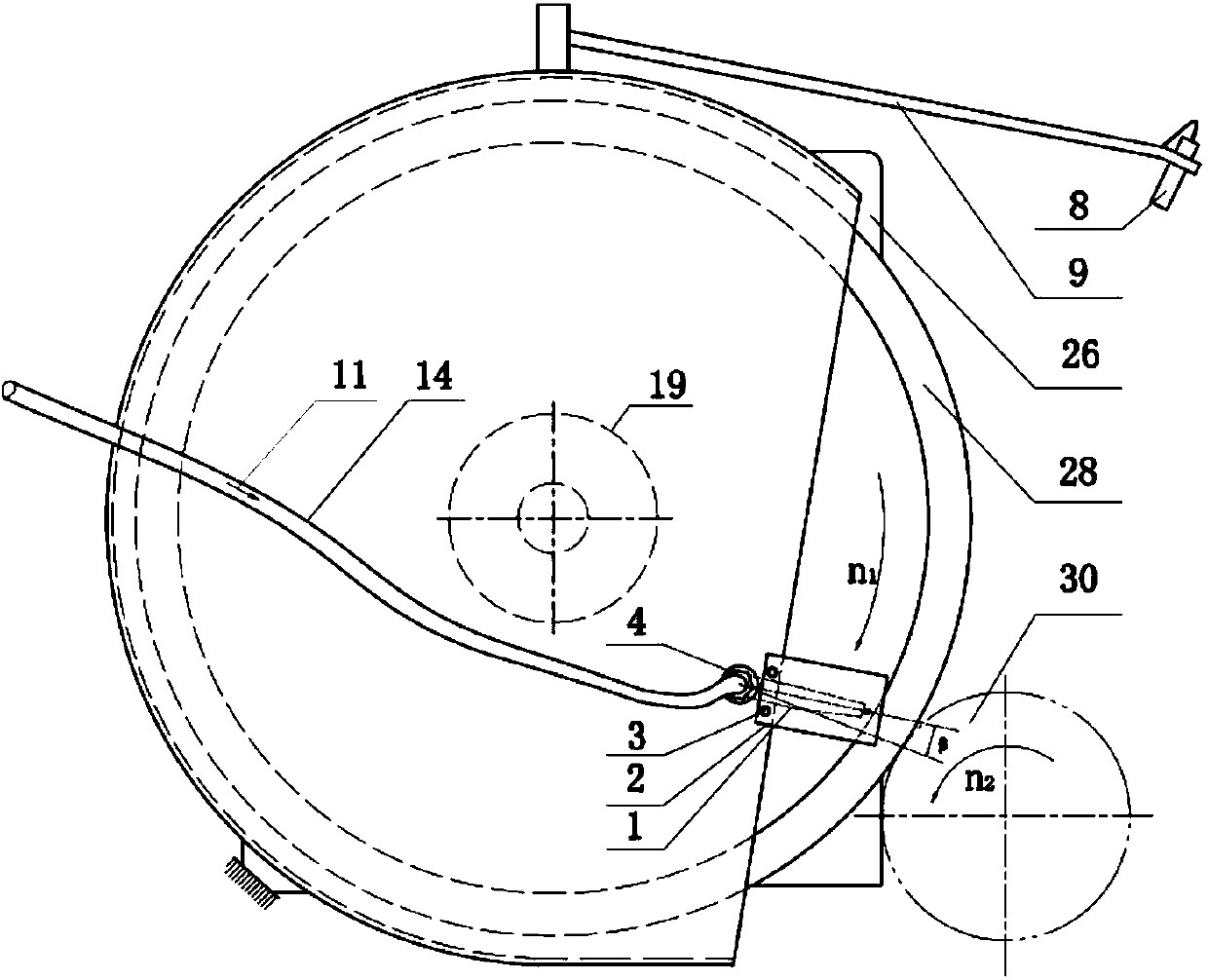

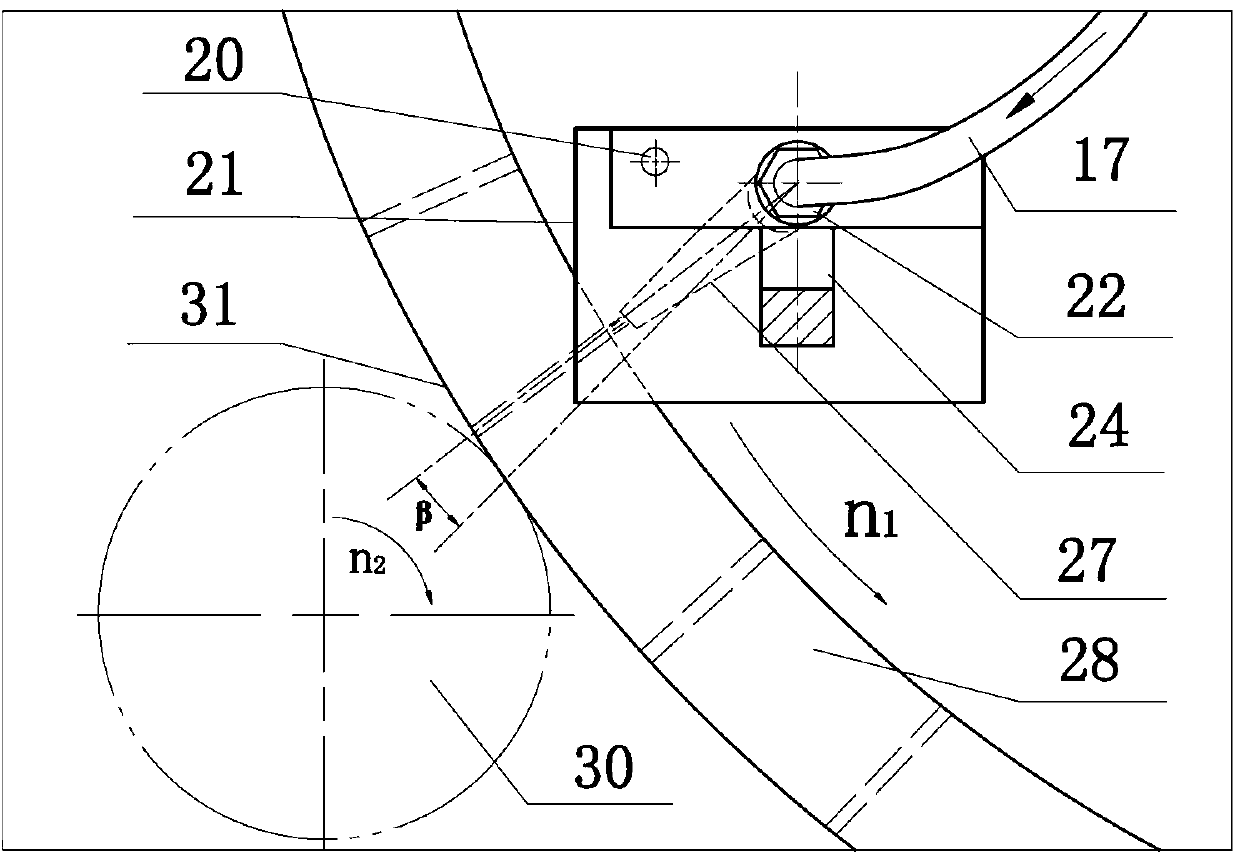

[0031] The grinding device of the invention comprises a grinding fluid flow control system, a grinding fluid delivery system and a grinding processing system. The grinding fluid flow control system includes an infrared thermometer 8, a magnetic base 9, a controller 7, a computer 6, a micro-motor 12, and a flow control valve 13. Grinding fluid delivery system includes grinding fluid source 10, grinding fluid 11, main pipeline 15, flow control valve 13, diverter valve 16, left nozzle 1, right nozzle 27, left guard plate 2, right guard plate 21 and nozzle hole 31. The grinding system includes a flange 18 , a spindle 19 , a headstock 26 , a grinding wheel 28 and a grinding wheel cover 29 .

[0032] Grinding wheel 28 is fixed on the main shaft 19 by headstock 26 by flange plate 18, and the grinding wheel cover 29 outside grinding wheel 28 is installed on the bed, and infrared thermometer 8 is fixed on the grinding wheel cover 29 by magnetic base 9, and faces grinding wheel. cut a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com