Porous carbon and nitrogen two-dimensional nanosheets and method for preparing ipmc electrochemical actuators

A two-dimensional nano, porous carbon technology, applied in nitrogen and non-metallic compounds, nanotechnology, nanotechnology, etc., can solve the problems of inability to further manufacture IPMC devices, low electrochemical activity of low-dimensional nanocarbon materials, etc., to achieve excellent Electromechanical response performance, excellent electrochemical energy storage, easy industrial production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

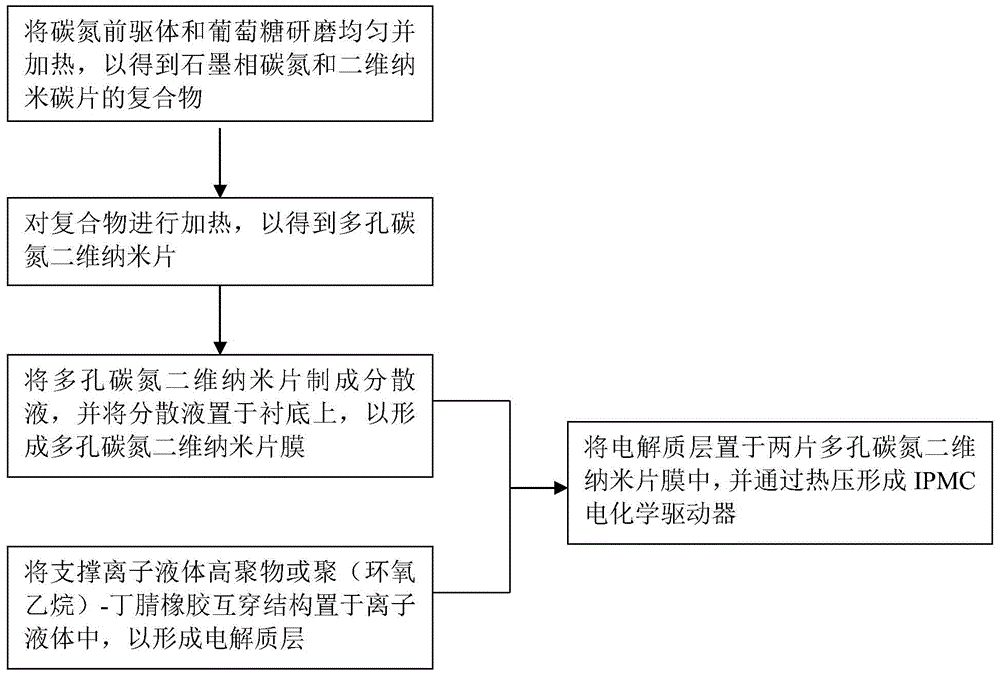

[0033] The method for preparing porous carbon-nitrogen two-dimensional nanosheets according to the present invention includes the following steps (a) and (b) performed in sequence.

[0034]Step (a): Grinding the carbon-nitrogen precursor and glucose (the mass ratio of the carbon-nitrogen precursor to glucose can be 100:1-1:1) to obtain a mixture evenly, and heating the mixture (for example, in a muffle furnace) to 450°C to 600°C to obtain a composite of graphite-phase carbon nitrogen and two-dimensional nano-carbon sheets. According to an embodiment of the present invention, the carbon-nitrogen precursor may include at least one selected from the group consisting of urea, dicyandiamide, melamine, and their respective mixtures with low-dimensional nanocarbon. Here, the low-dimensional nanocarbon can be carbon nanotubes or graphene, etc., and the stability of the material structure can be improved by adding low-dimensional nanocarbon. According to the embodiment of the present ...

Embodiment 1

[0047] Grind 10g of urea, 0.5g of glucose and 0.06g of single-walled carbon nanotubes (carbon nitrogen precursor: glucose is about 20:1) evenly, put them into a crucible, and dry them for one day. The mixture was placed in a muffle furnace, heated to 500°C at a heating rate of 5°C / min, and kept at this temperature for 3h to form a composite of gray graphite phase carbon nitrogen and two-dimensional carbon nanosheets. Afterwards, the compound was transferred to a tube furnace, and an inert gas (such as argon) or nitrogen was introduced at a rate of 200 sccm, kept at 100 °C for 1 h to remove water vapor, and then heated at a rate of 10 °C / min to 800°C, while keeping it warm for 1h until black porous carbon-nitrogen two-dimensional nanosheet powder is formed.

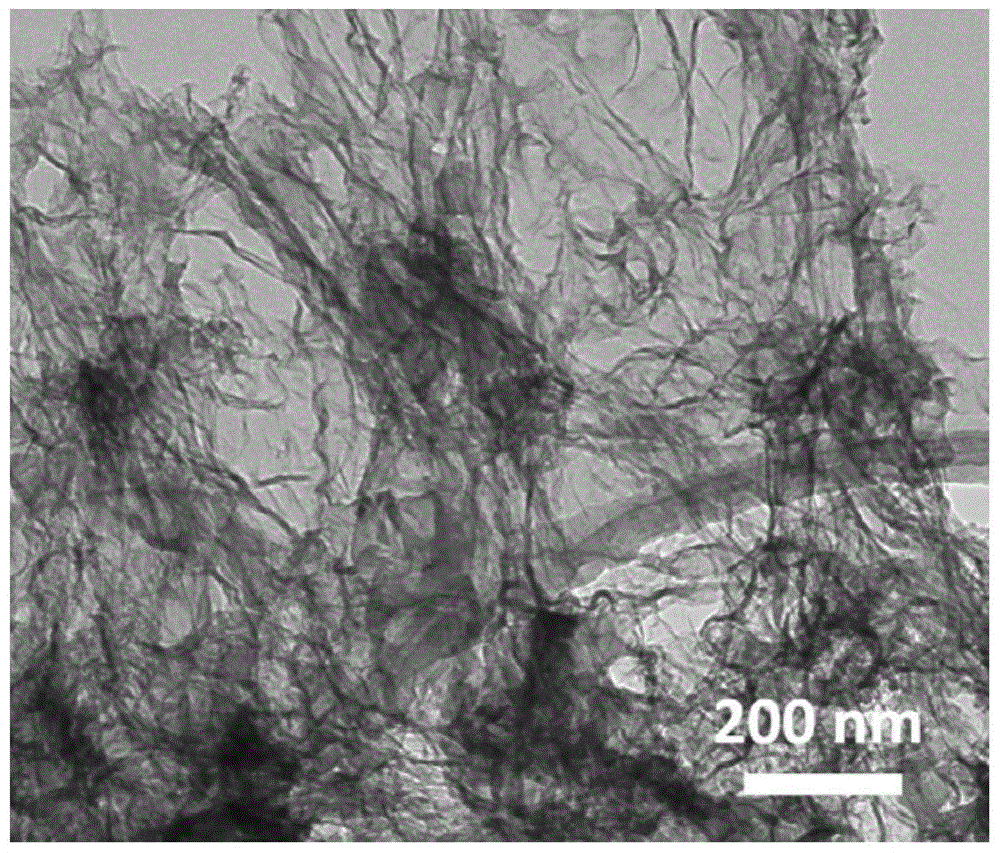

[0048] The mass fraction of nitrogen in the porous carbon-nitrogen two-dimensional nanosheet is 13.99%, and its conductivity is 382Sm -1 . in addition, figure 2 shows a transmission electron microscope image of a porou...

Embodiment 2

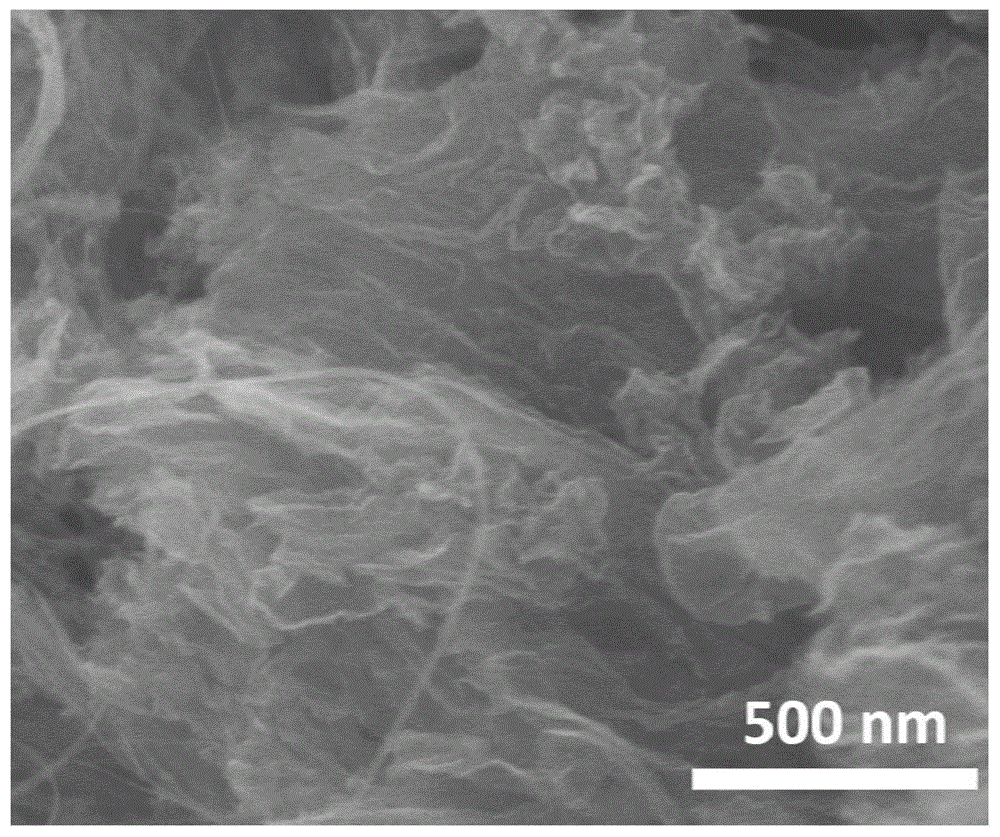

[0054] Grind 10g of urea, 0.5g of glucose and 0.06g of single-walled carbon nanotubes (carbon nitrogen precursor: glucose is about 20:1) evenly, put them into a crucible, and dry them for one day. The mixture was placed in a muffle furnace, heated to 500°C at a heating rate of 5°C / min, and kept at this temperature for 3h to form a composite of gray graphite phase carbon nitrogen and two-dimensional carbon nanosheets. Then transfer the above compound to a tube furnace, feed inert gas (such as argon) or nitrogen at a rate of 200 sccm, keep at 100°C for 1 hour to remove water vapor, and then raise the temperature to 700°C at a rate of 5°C / min , while keeping it warm for 5 hours until black porous carbon-nitrogen two-dimensional rice flake powder is formed. The mass fraction of nitrogen in porous carbon-nitrogen two-dimensional nanosheets is 16.56%, and the conductivity is 6.4Sm -1 , the pore size range is 0.93nm ~ 93.1nm.

[0055] 75 mg of porous carbon-nitrogen two-dimensional...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com