Anti-co interference ethanol sensing material

A technology of sensing materials and ethanol, which is applied in the field of gas-sensing sensing materials and preparation, anti-CO interference ethanol sensing materials and its preparation, and anti-CO interference gas-sensing sensing elements, which can solve the problem of stable initial resistance and interference signal , the resistance value is too large and other problems, to achieve the effect of small initial resistance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with example the present invention will be further described.

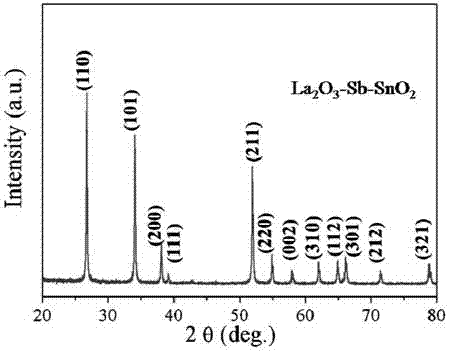

[0031] The anti-CO interference ethanol sensing material of the present embodiment, by mass, the ethanol sensing material consists of 0.5% La 2 o 3 Powder and 99.5% Sb doped SnO 2 made by mixing nanopowders, the Sb doped with SnO 2The molar ratio of Sb / Sn in the nanopowder is 0.1%.

[0032] 1. Preparation of the above-mentioned anti-CO interference ethanol sensing material

[0033] 1) Preparation of Sb-doped SnO 2 Nano powder

[0034] Weigh SnCl according to Sb / Sn molar ratio of 0.1% 4 ·5H 2 O and Sb 2 o 3 . SnCl 4 ·5H 2 O dissolved in ethanol to make tin chloride ethanol solution, SnCl 4 ·5H 2 The weight ratio of O and ethanol is 1:4. Will Sb 2 o 3 Dissolved in concentrated hydrochloric acid (HCl content in concentrated hydrochloric acid is 36 wt%) to make antimony-containing hydrochloric acid solution, Sb 2 o 3 The weight ratio with concentrated hydrochloric acid is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com