Nickel slag autoclaved aerated concrete block and preparation method thereof

A concrete block and autoclaved aerated technology, which is applied in the field of building materials, can solve the problems of cracking and damage of concrete blocks, high strength of autoclaved aerated concrete blocks, etc., and achieve the effect of uniform and stable pores and thickened slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

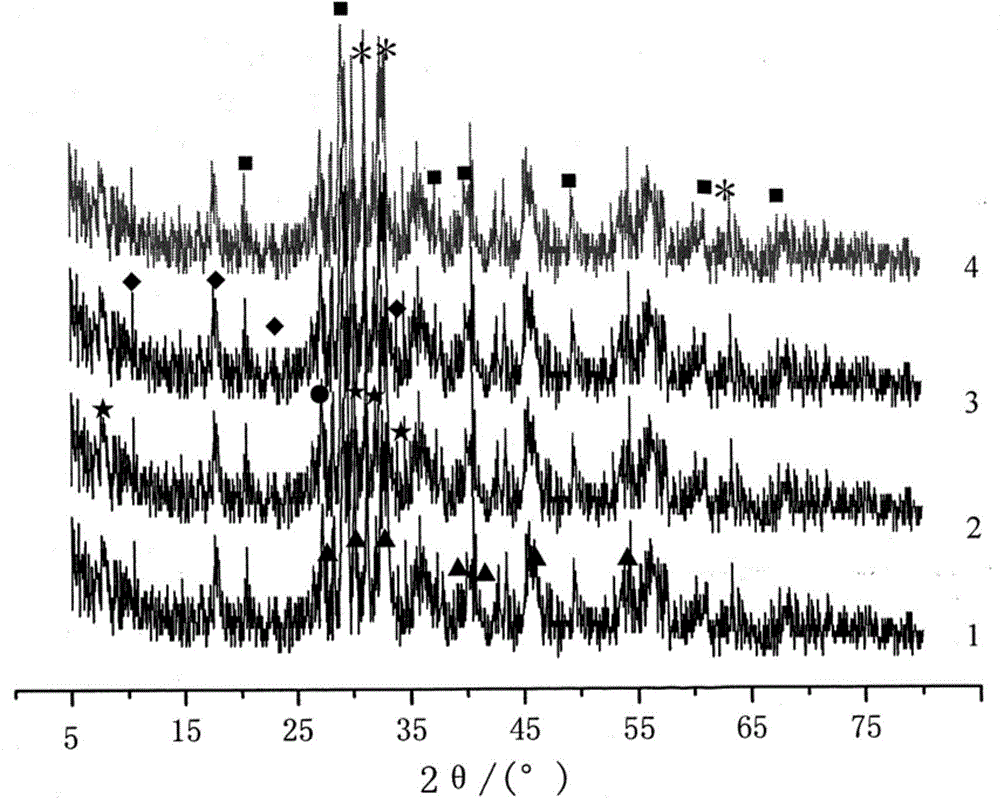

Image

Examples

preparation example Construction

[0067] As a preferred embodiment, the present invention provides a preparation method of the above-mentioned nickel slag autoclaved aerated concrete block, the specific steps are:

[0068] I. Preparation of Slurry

[0069] a. Take nickel slag, fly ash and gypsum in proportion by weight, mix them, and dry-grind them until the residue is less than 5% through a square-hole sieve with an aperture of 0.2 mm;

[0070] b. adding water in proportion to the mixture obtained in step a to prepare a mortar with a specific gravity of 1.5 to 1.8Kg / L for subsequent use;

[0071] c. according to the active calcium content of the base material, add an ion crystallizer to the mortar obtained in step b according to the molar ratio;

[0072] d. Take quicklime according to the weight ratio, crush and dry pulverize until the sieve residue is less than 5% through a square-hole sieve with an aperture of 0.2 mm to obtain quicklime powder;

[0073] e. the cement, the mortar obtained in step c and the...

Embodiment 1

[0087] Example 1 A nickel-based steam pressurized concrete block

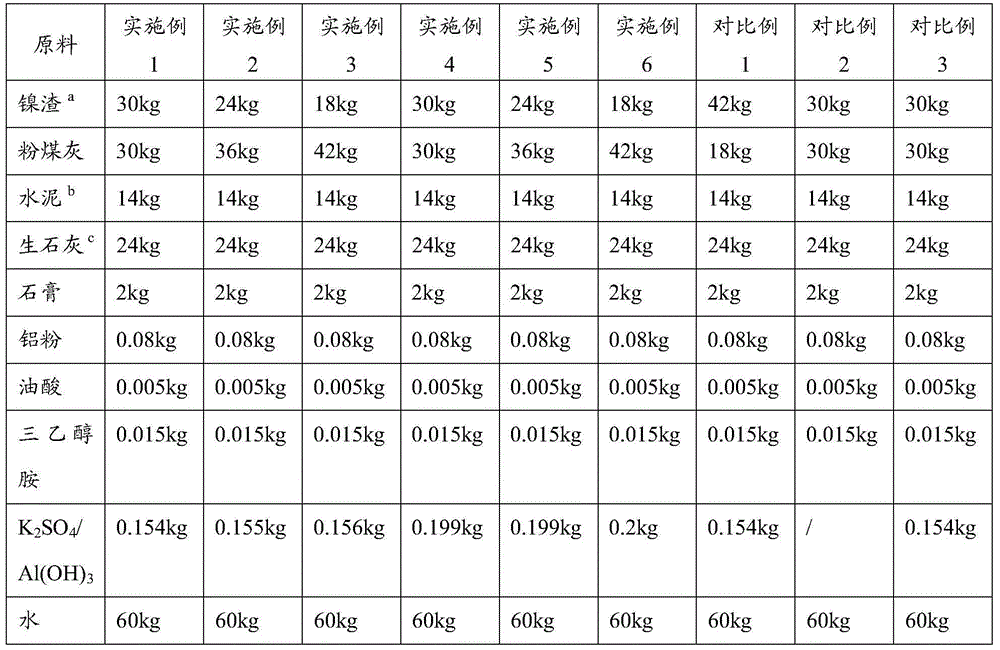

[0088] Raw material formula: shown in table 2; Wherein. The active calcium content of raw material is calculated to be 3.44kg, K + The molar ratio with the raw material active calcium is 0.02:1.

[0089] Prepared by the following method:

[0090] I. Preparation of slurry:

[0091] a. Take nickel slag, fly ash and gypsum, mix them, and dry-grind them to less than 5% after passing through a square-hole sieve with an aperture of 0.2 mm;

[0092] B. add whole water in the mixture that step a obtains, make the mortar of specific gravity 1.72Kg / L for subsequent use;

[0093] c. Take K 2 SO 4 adding to the mortar obtained in step b;

[0094] d. Take quicklime, crush and dry-pulverize it until the sieve remainder is less than 5% through a square-hole sieve with an aperture of 0.2 mm to obtain quicklime powder;

[0095] e. the cement, the mortar obtained in step c and the quicklime powder obtained in step d are...

Embodiment 2

[0106] Example 2 A nickel-based steam pressurized concrete block

[0107] Raw material formula: see Table 2. Among them, the active calcium content of the calculated raw material is 3.45kg, K + The molar ratio with the raw material active calcium is 0.02:1.

[0108] Prepared by the following method:

[0109] I. Preparation of slurry:

[0110] a. Take nickel slag, fly ash and gypsum, mix them, and dry-grind them to less than 5% after passing through a square-hole sieve with an aperture of 0.2 mm;

[0111] B. add whole water in the mixture that step a obtains, make the mortar of specific gravity 1.64g / L for subsequent use;

[0112] c. Take K 2 SO 4 adding to the mortar obtained in step b;

[0113] d. Take quicklime, crush and dry-pulverize it until the sieve remainder is less than 5% through a square-hole sieve with an aperture of 0.2 mm to obtain quicklime powder;

[0114] e. the cement, the mortar obtained in step c and the quicklime powder obtained in step d are mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com