Method for extracting lycorine from Lycoris plants

A technology of lycoris and lycorine, applied in the direction of organic chemistry, can solve the problems of high price of ethyl acetate, high production cost, cumbersome operation, etc., and achieve the effect of low production cost, short reaction time and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described with reference to the accompanying drawings and embodiments.

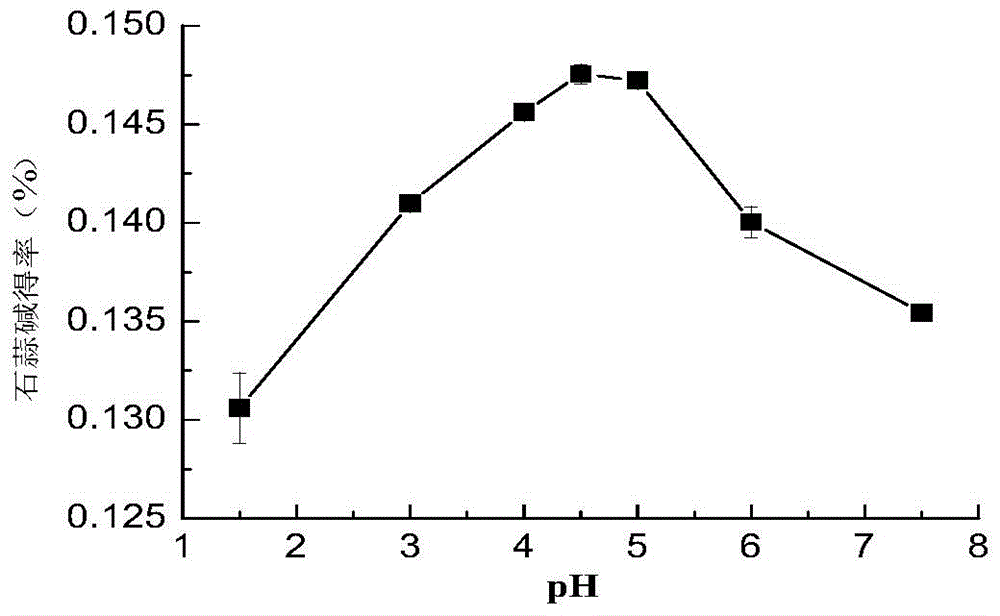

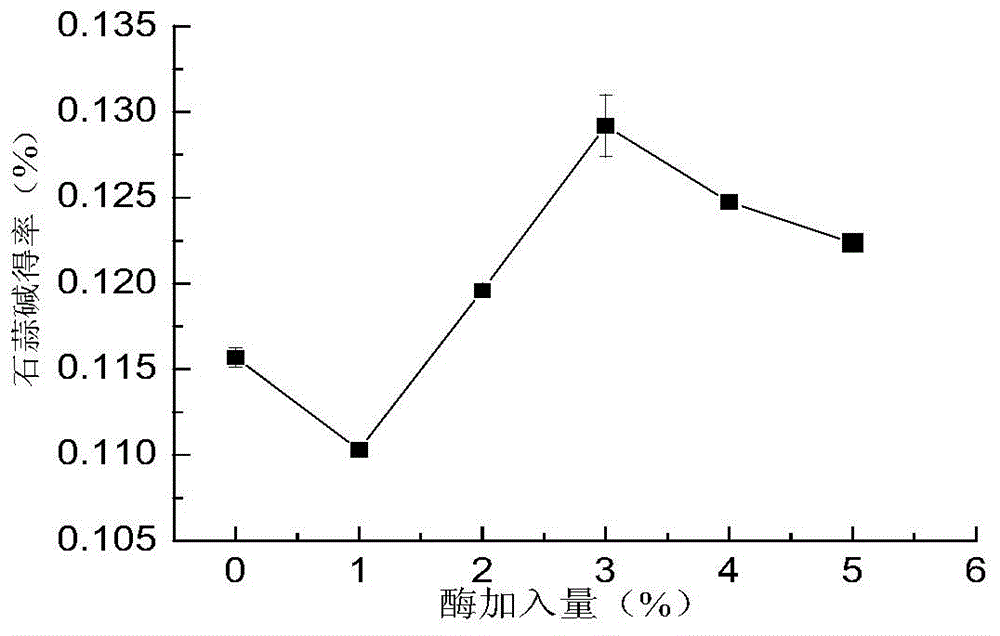

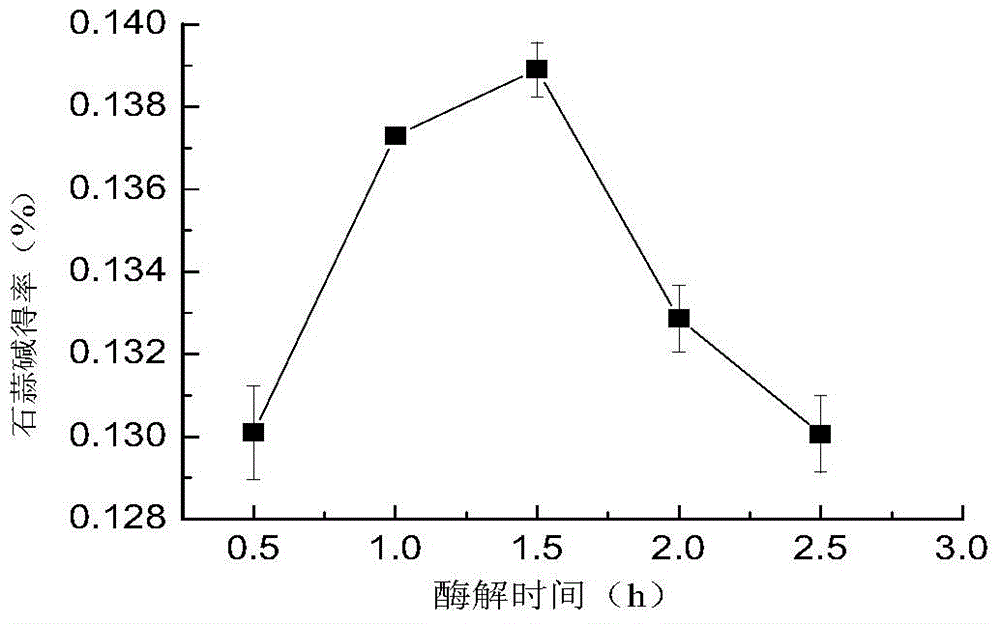

[0027] The present embodiment comprises the following steps: (1) Extraction: First, weigh 2.000 g of Lycoris plant powder that has been dried, pulverized, and sieved, and the ratio of solid to liquid is 1:5-25, and the unit ratio is g / mL. Add water whose pH is adjusted to 1.5-7.5, add enzymes of 1%-5% of Lycoris plant powder mass, enzymolyze at 40-80°C for 0.5-2.5h, centrifuge for 20min, filter, and take the supernatant to obtain the stone Garlic alkali extract;

[0028] (2) Purification

[0029] ①Solvent extraction: adjust the pH of the lycorine extract extracted in step (1) to 10 with NaOH, add the extraction agent chloroform at a volume ratio of 1:1, shake well, let stand overnight, remove the lower chloroform phase, and adjust with HCl pH to 2, suction filtration to obtain lycorine extract concentrate;

[0030] ②Cation exchange resin adsorption: adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com