Synthesis method of special catalyst for addition-type high refractive index LED encapsulation resin

A technology of LED packaging and high refractive index, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing the initial heat release peak, too fast rise in viscosity, shortening the operating time window, etc., to achieve the reduction of vinyl content, Good compatibility, reduced handling and contamination loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

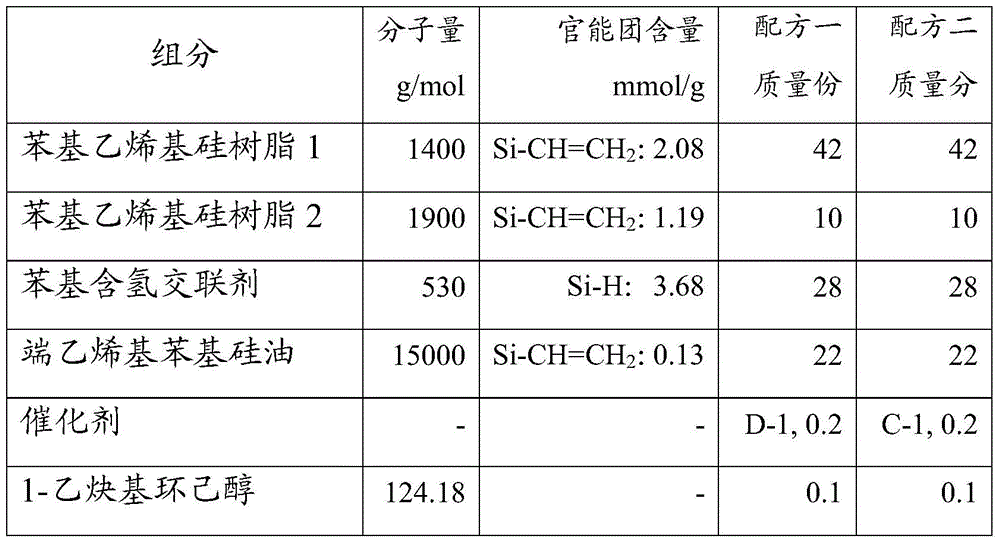

[0031] The synthesis of embodiment 1 vinyl phenyl silicone resin

[0032] 1.1 Synthesis of vinylphenyl silicone resin V-11

[0033] Add 978.75g (5.25mol) divinyltetramethyldisiloxane, 2082g (10.5mol) phenyltrimethoxy Silane, 458g (1wt%) sulfuric acid aqueous solution, equipped with mechanical stirring, thermometer, dean-stark tube and condenser tube, receiving bottle, after the mixture was stirred at room temperature for 1.5 hours, the temperature of the liquid was raised to 40 ° C, at this time the oil The heating temperature of the bath was raised to 70° C., and after stirring and reacting for 3 hours, the temperature of the oil bath was raised to 100° C. to distill out the generated by-products. The distillation continued for about 2 hours, at which time the temperature of the reaction mixture rose to 90°C. Stirring and heating were discontinued and the reaction mixture was allowed to stand overnight. Add 2.6g of potassium hydroxide, 700mL of toluene and 13mL of water to...

Embodiment 2

[0040] The synthesis of embodiment 2 Pt-divinyltetramethyldisiloxane solution

[0041] 2.1 Add 1g of chloroplatinic acid hexahydrate (molecular formula H 2 PtCl 6 6H 2 (0, effective Pt content ≥ 37%), 30mL absolute ethanol, 10g divinyltetramethyldisiloxane, and 3g sodium bicarbonate powder, equipped with a magnetic stirring oil bath heating device and a condenser, to the reaction system Under the protection of nitrogen gas, the temperature was raised to 70° C. for 1 hour, and the mixture changed from brownish red to light yellow at first, and the obtained mixture was named B-1.

[0042] 2.2 Add 1g of chloroplatinic acid hexahydrate (molecular formula H 2 PtCl 6 6H 2 (0, effective Pt content ≥ 37%), 60mL absolute ethanol, 40g divinyltetramethyldisiloxane, and 5g sodium bicarbonate powder, equipped with a magnetic stirring oil bath heating device and a condenser, to the reaction system Under nitrogen protection, the temperature was raised to 65°C for 0.5 hour reaction, the...

Embodiment 3

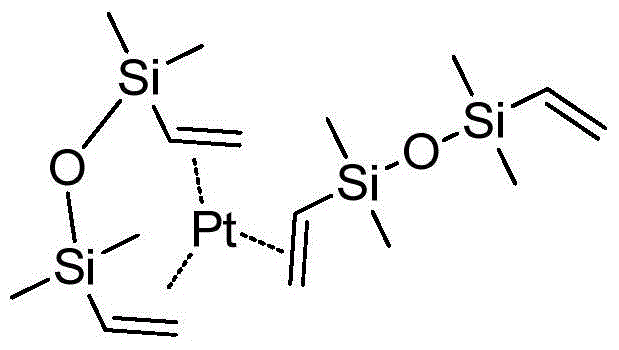

[0044] The synthesis of embodiment 3 catalyst

[0045] 3.1 Synthesis and post-treatment of a highly active low-vinyl high-phenyl catalyst with an active ingredient content of 5000ppm:

[0046] The reaction mixture B-1 prepared in Example 2 and the low-viscosity, low-vinyl content, high-phenyl ligand resin V-11 prepared in 74g of Example 1 were jointly added in a 500mL single-mouthed eggplant-shaped bottle, and were mixed with a rotary evaporator. At 60°C, under the condition of air pressure <1mbar, vacuumize to remove low boilers. The obtained turbid liquid was filtered once to obtain a pale yellow transparent Pt-resin complex with an active ingredient content of 5000 ppm, which was named as C-1.

[0047] 3.2 Synthesis and post-treatment of a highly active low-vinyl high-phenyl catalyst with an active ingredient content of 1000ppm:

[0048] The reaction mixture B-2 prepared in Example 2 and the low-viscosity, low-vinyl content, and high-phenyl ligand resin V-23 prepared in 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

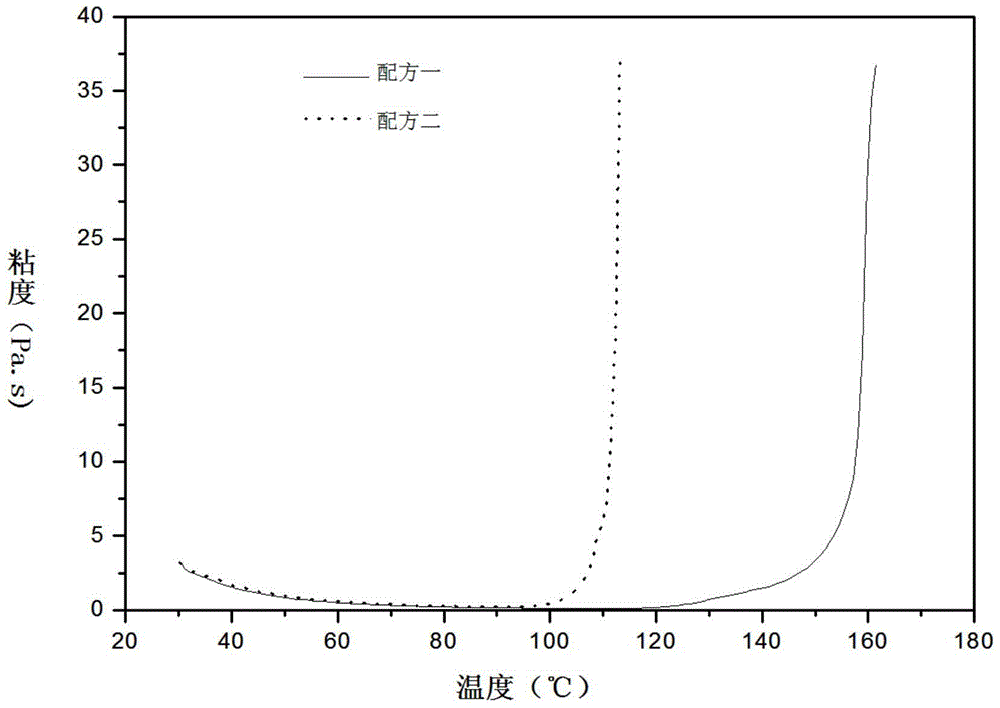

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com