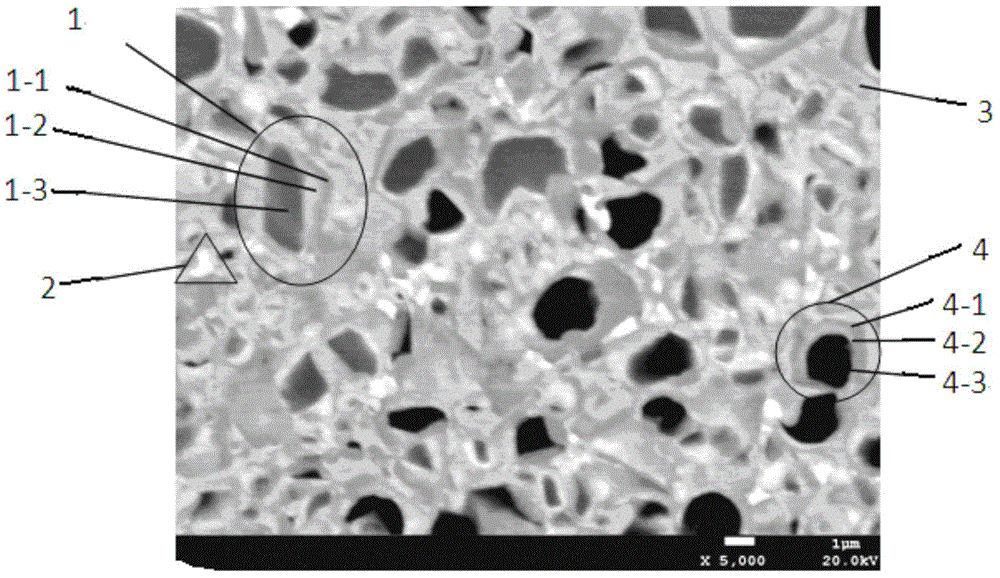

Cermet material based on TiCN-(Ti,M)CN core mixed structure and preparation method thereof

A technology of cermet and mixed powder, which is applied in the field of cermet, can solve the problems that the toughness and hardness cannot be taken into account, the performance cannot be improved at the same time, and the application of cermet is limited, so as to achieve good comprehensive mechanical properties, low equipment requirements, improve toughness and The effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Based on 20TiCN-80 (Ti, 15W, 5Mo, 0.2V) (C 0.5 N 0.5 ) The preparation method of the cermet material of mixed core structure, the component of raw material and the mass percent of each component are:

[0035]

[0036] The process steps are as follows:

[0037] (1) Mixing and granulation

[0038] Measure each raw material according to the mass percentage of the above raw materials, put the measured raw materials into a Ф10mm polyurethane grinding tank with YG8 cemented carbide balls, add 1L of alcohol, and ball mill at a ball milling speed of 24r / min for 90 hours to obtain a mixed wet material. The YG8 cemented carbide balls were added according to the mass ratio of balls to materials at 8:1. After the ball milling, the obtained mixed wet material was vacuum-dried at 70° C. for 16 hours, and then 2.5% of its mass was added to the mixed powder obtained by vacuum drying. The polyethylene glycol-alcohol solution is mixed with glue and granulated to form a granular mix...

Embodiment 2

[0045] Based on 50TiCN-50 (Ti, 20W, 15Ta, 0.2V) (C 0.7 N 0.3 ) The preparation method of the cermet material of mixed core structure, the component of raw material and the mass percent of each component are:

[0046]

[0047]

[0048] The process steps are as follows:

[0049] (1) Mixing and granulation

[0050] Measure each raw material according to the mass percentage of the above raw materials, put the measured raw materials into a Ф10mm polyurethane grinding tank with YG8 cemented carbide balls, add 800mL of alcohol, and ball mill at a ball milling speed of 24r / min for 72 hours to obtain a mixed wet material. The YG8 cemented carbide balls are added according to the mass ratio of balls to materials at 8:1. After the ball milling, the obtained mixed wet material is vacuum-dried at 70° C. for 18 hours, and then 0.5% of its mass is added to the mixed powder obtained by vacuum drying. The polyethylene glycol-alcohol solution is mixed with glue and granulated to form a...

Embodiment 3

[0058] Based on 40TiCN-60 (Ti, 20W, 5Ta, 0.5Nb) (C 0.7 N 0.3 ) The preparation method of the cermet material of mixed core structure, the component of raw material and the mass percent of each component are:

[0059]

[0060]

[0061] The process steps are as follows:

[0062] (1) Mixing and granulation

[0063] Measure each raw material according to the mass percentage of the above raw materials, put the measured raw materials into a Ф10mm polyurethane grinding tank with YG8 cemented carbide balls, add 800mL of alcohol, and ball mill at a ball milling speed of 24r / min for 72 hours to obtain a mixed wet material. The YG8 cemented carbide balls are added according to the mass ratio of balls to materials at 10:1. After the ball milling, the mixed wet material obtained is vacuum-dried at 60°C for 24 hours, and then 2% of its mass is added to the mixed powder obtained by vacuum drying. SD glue is blended and granulated to form a granular mixture;

[0064] (2) Molding

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com