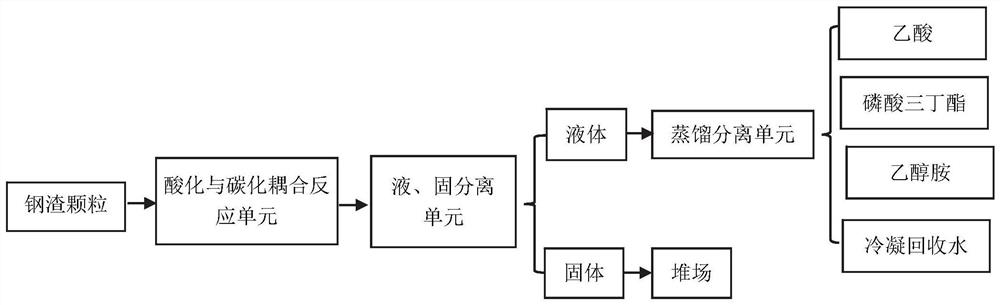

A Process for Coupling Acidification and Carbonization Modified Steel Slag

A technology of steel slag modification, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of low carbonation reaction rate, severe comprehensive treatment of steel slag, high pressure and other problems, and achieve the elimination of volume stability Sexuality problems, elimination of poor volume stability, and the effect of increasing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

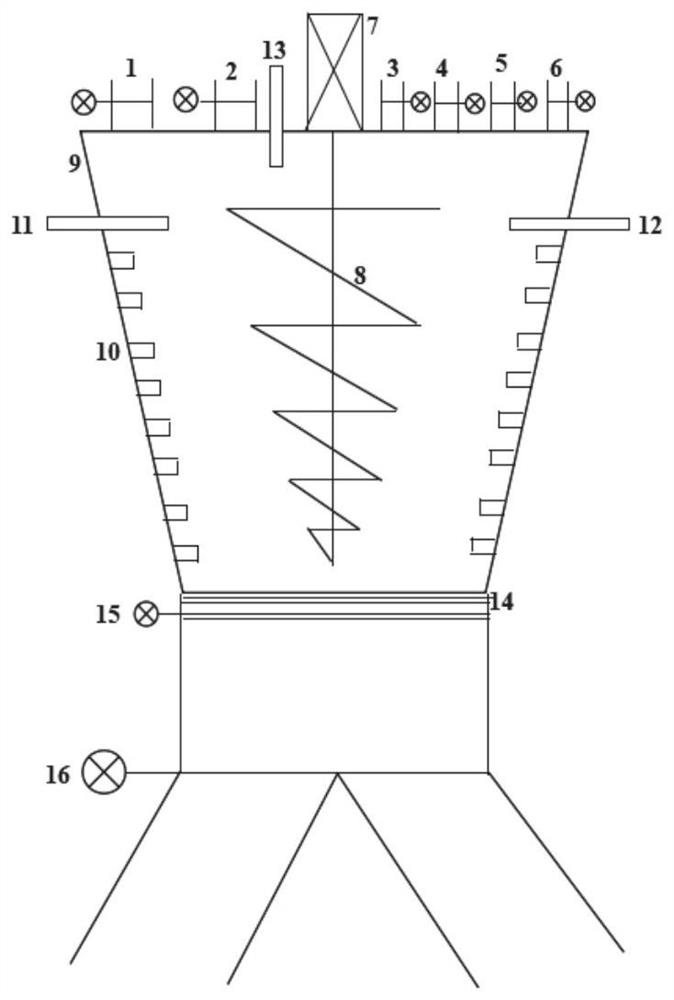

[0073] A process for coupling acidification and carbonization to modify steel slag:

[0074] (1) The steel slag particles are transported into the acidification and carbonization coupling reaction unit. For details of the equipment number, please refer to figure 2 , enter the reaction chamber 9 through 1, add circulating water into the reaction device through 6, set the liquid-solid ratio at 5:1 to control the amount of water added, start the motor 7 to drive the stirring shaft 8 with a spiral blade to move, and pass the acetic acid in batches. The solid acetic acid was added to the feed port 3, and after stirring and reacting for 20 minutes, tributyl phosphate was added through the tributyl phosphate feed port 4, and at the same time, CO containing CO was sprayed through the lime kiln flue gas nozzle 10. 2 The flue gas from the lime kiln was controlled at 0.1MPa, and ethanolamine (5%) was added in batches through the ethanolamine feed port 5 to increase the CO 2 Solubility ...

Embodiment 2

[0078] A process for coupling acidification and carbonization to modify steel slag:

[0079] (1) The steel slag particles are transported into the acidification and carbonization coupling reaction unit. For details of the equipment number, please refer to figure 2 , which enters the reaction chamber 9 through 1, the circulating water is added to the reaction device through 6, the liquid-solid ratio is set at 20:1 to control the amount of water added, the motor 7 is started to drive the stirring shaft 8 with a spiral blade to move, and the acetic acid is passed in batches. The solid acetic acid was added to the feed port 3, and after stirring and reacting for 60 minutes, tributyl phosphate was added through the tributyl phosphate feed port 4, and at the same time, the CO containing CO was sprayed through the lime kiln flue gas nozzle 10. 2 The flue gas from the lime kiln was controlled at 2MPa, and ethanolamine (20%) was added in batches through the ethanolamine feed port 5 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com