LED (light emitting diode) with dual-reflector structure and manufacturing method of LED with dual-reflector structure

A technology of light-emitting diodes and double mirrors, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of low light extraction efficiency and poor N-surface current expansion effect, and achieve simple manufacturing process, good product stability, and high The effect of reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] One, the manufacturing steps of the present invention are as follows:

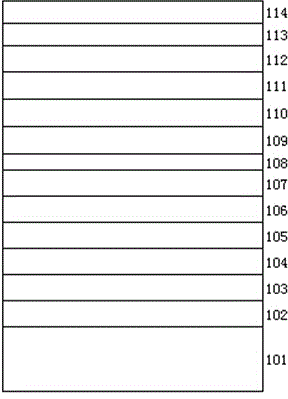

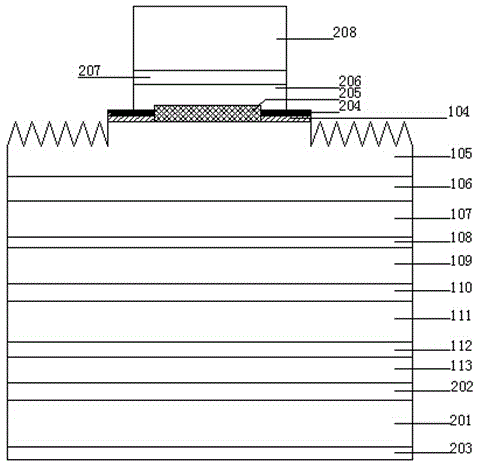

[0041] 1. If figure 1 As shown, a transition layer 102, an N-GaInP cut-off layer 103, an N-GaAs ohmic contact layer 104, an N-AlGaInP roughening layer 105, and an N-AlGaInP current spreading layer 106 are sequentially grown on a temporary GaAs substrate 101 by using MOCVD equipment. , N-AlGaInP confinement layer 107, MQW multiple quantum well active layer 108, P-AlGaInP confinement layer 109, buffer layer 110, P-GaP current spreading layer 111.

[0042] Wherein the N-GaAs ohmic contact layer 104 preferably has a thickness of 60nm, the doped impurity element is Si, and the doping concentration is 8×10 18 cm -3 above to ensure a good electrical contact on the N side.

[0043] The preferred thickness of the P-GaP current spreading layer 111 is 3000nm, the doped impurity element is Mg, and the doping concentration is 7×10 18 cm -3 above to ensure a good electrical contact on the P side.

[0044]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com