Fault-tolerant operation method of switched reluctance motor speed control system based on simplified flux linkage method

A technology of switched reluctance motor and speed control system, which is applied in control systems, control generators, vector control systems, etc., can solve the problems of paralysis of the operation system and disorder of position estimation signals, and achieve the effect of improving operation stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

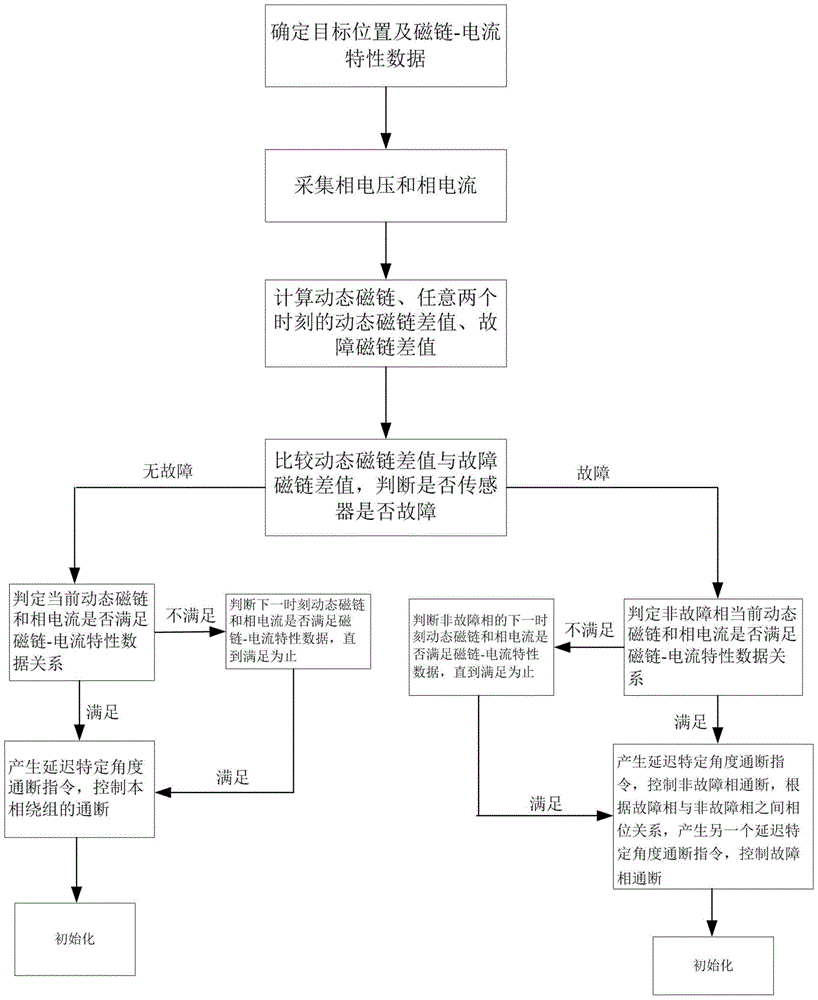

[0022] A fault-tolerant operation method for a switched reluctance motor speed control system based on a simplified flux linkage method. The switched reluctance motor system includes a switched reluctance motor, a power converter unit for driving the switched reluctance motor, and signal acquisition and processing for collecting phase current and phase voltage unit and a control unit, the method includes the steps of:

[0023] Step 1: Select the rotor position corresponding to the intersection point of the phase inductance curve, and define it as the target position. At the target position, measure the flux linkage-current characteristic data of the phase winding, and store the flux linkage-current characteristic data in the control unit;

[0024] Step 2 The signal acquisition and processing unit collects the phase voltage and phase current in real time, and converts the phase voltage value U k and phase current value i k transmitted to the control unit;

[0025] Step 3 Star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com