Biological full-degradable polylactic acid/plant fiber composite material as well as preparation method and application thereof

A technology of plant fibers and composite materials, which is applied in the field of polylactic acid composite materials, can solve the problems that the toughness and impact resistance cannot meet the actual use requirements, is not suitable for industrial large-scale production, and needs to be further improved, and achieves simple and efficient processing performance. , small density, the effect of preventing the entry of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

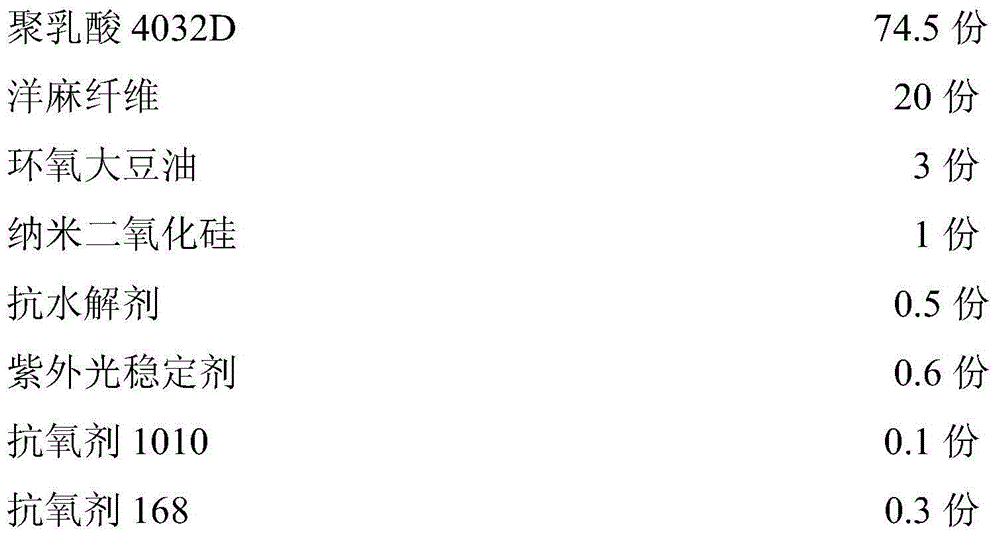

[0029] The formula is as follows:

[0030]

[0031] Weigh the following ingredients by weight:

[0032] Polylactic acid 4032D (Natureworks, USA) 74.5Kg, kenaf fiber (5mm-10mm in diameter, Gaobeidian Liangjiaying Shengli Hemp Rope Processing Factory) 20Kg, epoxy soybean oil (epoxy value greater than 6%, plasticized by Changzhou Carter) Technology Co., Ltd.) 3Kg, nano-silica (AEROSIL R974, Evonik Degussa) 1Kg, anti-hydrolysis agent 0.5kg (BioAdimide 100, German Rhein Chemie), UV stabilizer 0.6Kg (UV-531, Nanjing Economic Tianwei Chemical Co., Ltd.) antioxidant 1010 (Shanghai Jinghong Industrial Co., Ltd.) 0.1Kg, antioxidant 168 (Shanghai Jinghong Industrial Co., Ltd.) 0.3Kg.

[0033] The preparation process is as follows:

[0034] At 105°C, use a high-speed mixer to mix polylactic acid, plant fibers and inorganic nanoparticles uniformly and dry them, then add bio-based epoxy compounds and additives and mix uniformly, and then use a twin-screw extruder to melt extrude Extru...

Embodiment 2

[0036]

[0037] Weigh the following ingredients by weight:

[0038]Polylactic acid 4032D (Natureworks, USA) 71.5Kg, kenaf fiber (5mm-10mm in diameter, Gaobeidian Liangjiaying Shengli Hemp Rope Processing Factory) 20Kg, epoxy soybean oil (epoxy value greater than 6%, plasticized by Changzhou Carter) Technology Co., Ltd.) 5Kg, nano-silica (AEROSIL R974, Evonik Degussa) 2Kg, anti-hydrolysis agent 0.5kg (BioAdimide 100, German Rhein Chemie), UV stabilizer 0.6Kg (UV-531, Nanjing Economic Tianwei Chemical Co., Ltd.) antioxidant 1010 (Shanghai Jinghong Industrial Co., Ltd.) 0.1Kg, antioxidant 168 (Shanghai Jinghong Industrial Co., Ltd.) 0.3Kg.

[0039] The preparation process is as described in Example 1.

Embodiment 3

[0041] The formula is as follows:

[0042]

[0043] Weigh the following ingredients by weight:

[0044] Polylactic acid 4032D (Natureworks, USA) 68.5Kg, kenaf fiber (5mm-10mm in diameter, Gaobeidian Liangjiaying Shengli Hemp Rope Processing Factory) 20Kg, epoxy soybean oil (epoxy value greater than 6%, plasticized by Changzhou Carter) Technology Co., Ltd.) 7Kg, nano-silica (AEROSIL R974, Evonik Degussa) 3Kg, anti-hydrolysis agent 0.5kg (BioAdimide 100, German Rhein Chemie), UV stabilizer 0.6Kg (UV-531, Nanjing Tianwei Chemical Co., Ltd.) antioxidant 1010 (Shanghai Jinghong Industrial Co., Ltd.) 0.1Kg, antioxidant 168 (Shanghai Jinghong Industrial Co., Ltd.) 0.3Kg.

[0045] The preparation process is as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com