Spacer fluid for penetrating selective plugging agent and application method of spacer fluid

A spacer and selective technology, applied in the field of spacer, can solve the problems of reduced coagulation performance, short plugging time, and low degree of sweeping of low-permeability layers, so as to prevent incomplete curing, improve plugging ability, and improve cementing ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

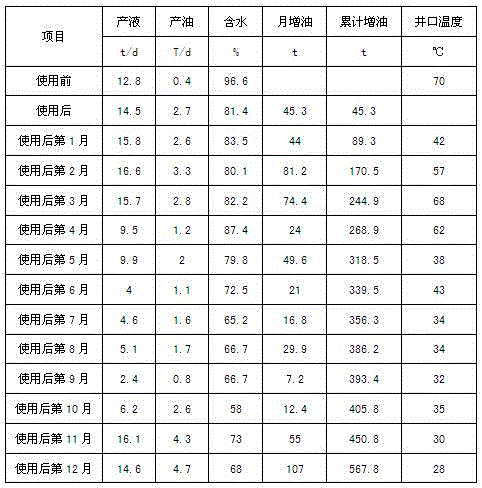

[0017] This example involves several groups of spacers for permeation-selective plugging agents, and the formulations are shown in the table below:

[0018]

[0019] According to the formula in the above table, add the three kinds of materials into the water one by one, mix and stir evenly to obtain the spacer for permeation selective blocking agent.

Embodiment 2

[0021] This example relates to the test on the effect of the spacer in Example 1.2.

[0022] Preparation before construction:

[0023] ①. Pull out the production string in the well, remove wax, and measure;

[0024] ②. The lower scraping pipe string, the lower sand flushing pipe string, the clean water flushes the sand to the bottom of the artificial well, and circulates the well to achieve the same water quality at the inlet and outlet;

[0025] ③. Start the sand flushing string, squeeze the injection string, install the wellhead, expand the packer, and pull out the dead core;

[0026] ④. Squeeze the injection equipment to the well site, connect the equipment and pipelines, prepare the spacer fluid for the permeable selective plugging agent according to the formula in Example 1.2; add 0.5 g of sodium hydroxycarboxylate, 2 g of sodium nitrite, and lithium aluminum silicon to 400 g of water in sequence 20g salt, 8g acrylamide copolymer, 10g oil well cement (average particle s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com