Method for improving conversion efficiency of converting phytosterol into androstenedione

A technology of phytosterols and diketones, applied in the field of preparation of androst-4-ene-3, which can solve the problems of low solubility, increase of miscellaneous bacteria, excessive microbial fermentation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

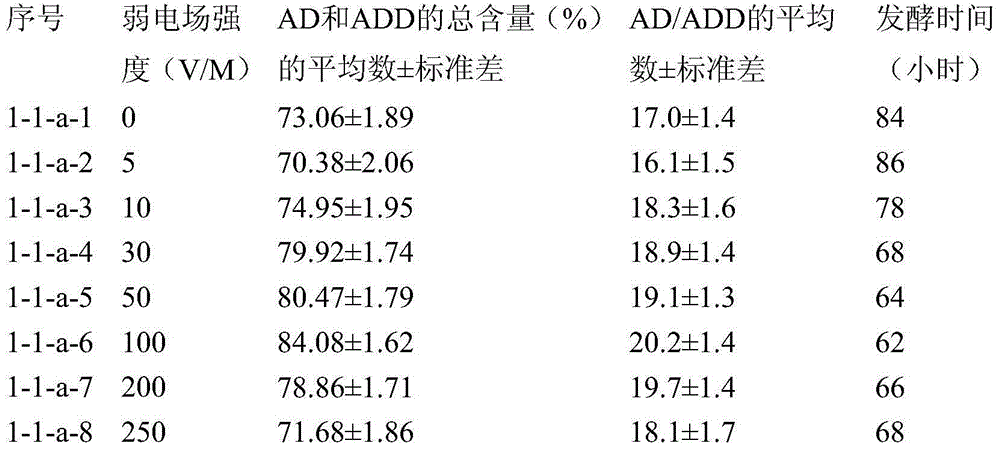

Embodiment 1-1-a

[0060] Species: Mycobacterium: Mycobacterium fortuitum. NRRL B-8153.

[0061] Take 10 different batches of corn steep liquor and ferment them respectively according to the quantity and process in this example. Except corn steep liquor, other materials are the same batch of materials.

[0062] Seed culture stage:

[0063] Seed medium (per liter):

[0064] 40ml corn syrup

[0065] 5.2g NaNO 3 ,

[0066] 0.8g NH 4 h 2 PO 4

[0067] 5.3g glucose

[0068] The rest is sterile water

[0069] Medium volume: 200ml / flask

[0070] Inoculum volume: Inoculate 3ml of cell suspension from agar slant per 200ml of new medium

[0071] Container: 1000ml conical flask

[0072] Stirring: Shaker (1”throw) 200rpm

[0073] Temperature: 30°C

[0074] Growth time: 72 hours culture

[0075] Note: A good culture organism is indicated if a yellow cell pellet forms at the bottom

[0076] method:

[0077] Inoculum for biotransformation was prepared in culture medium. Inoculate Erlenmeyer ...

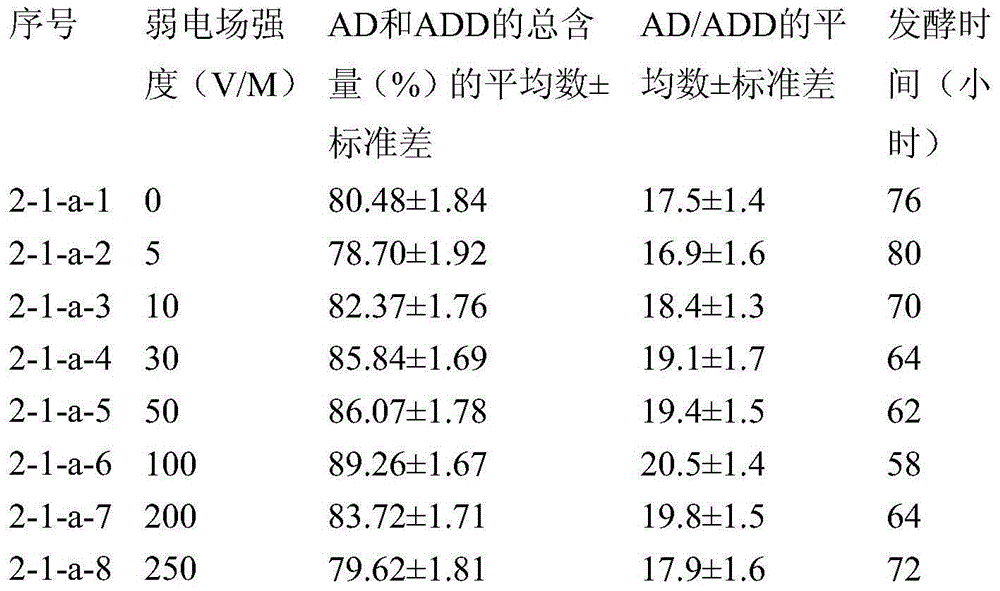

Embodiment 2-1-a

[0097] Take 10 different batches of corn steep liquor and ferment them respectively according to the quantity and process in this example. Except corn steep liquor, other materials are the same batch of materials.

[0098] The process of this embodiment is the same as the method of Example 1-1-a, and the detection method is the same, but the strain is changed to mycobacterium: Mycobacterium sp NRRL-B3683, and the culture medium is changed as follows:

[0099] Seed culture stage:

[0100] Seed medium (per liter):

[0101] 10ml corn syrup

[0102] 8.7g NaNO 3 ,

[0103] 0.3g NH 4 h 2 PO 4

[0104] 15g glucose

[0105] Na 2 HPO 4 and NaH 2 PO 4 Adjust the pH of the buffer to 7.0

[0106] The rest is sterile water

[0107] Medium volume: 200ml / flask

[0108] Inoculum volume: Inoculate 3ml of cell suspension from agar slant per 200ml of new medium

[0109] Container: 1000ml conical flask

[0110] Stirring: Shaker (1”throw) 200rpm

[0111] Temperature: 30°C

[01...

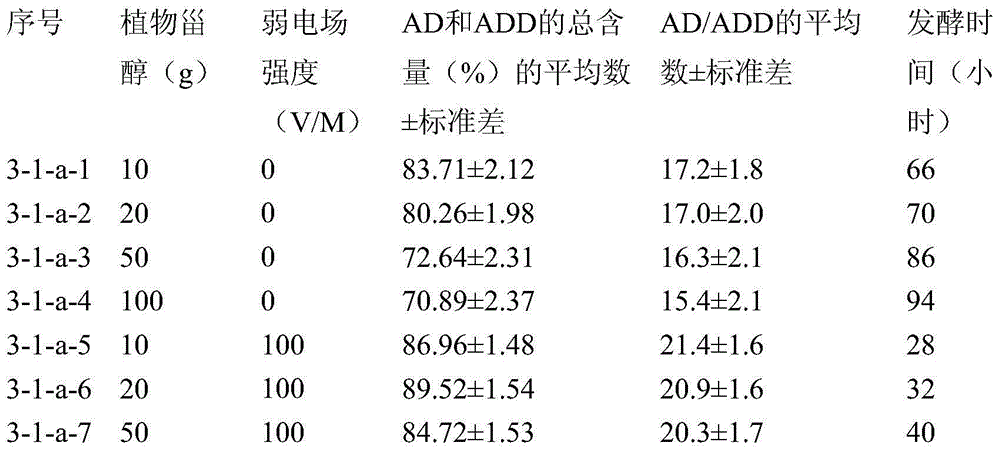

Embodiment 3-1-a

[0125] Take 10 different batches of corn steep liquor and ferment them respectively according to the quantity and process in this example. Except corn steep liquor, other materials are the same batch of materials.

[0126] The process of this embodiment is the same as the method of Example 1-1-a, and the detection method is the same, but the strain is changed to mycobacterium: Mycobacterium sp NRRL-B3805, and the culture medium is changed as follows:

[0127] Seed culture stage:

[0128] Seed medium (per liter):

[0129] 25ml corn syrup

[0130] 4g NaNO 3 ,

[0131] 1g NH 4 h 2 PO 4

[0132] 1g FeCl 2

[0133] 15g glucose

[0134] Na 2 HPO 4 and NaH 2 PO 4 Adjust the pH of the buffer to 7.0

[0135] The rest is sterile water

[0136] Medium volume: 200ml / flask

[0137] Inoculum volume: Inoculate 3ml of cell suspension from agar slant per 200ml of new medium

[0138] Container: 1000ml conical flask

[0139] Stirring: Shaker (1”throw) 200rpm

[0140] Tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com