System and method for three-dimensional characterization of blade tip gaps and dynamic detection of optical fibers of aero-engine

An aero-engine and blade tip clearance technology, applied in the field of aero-engines, can solve the problems of inability to accurately extract fault features, no detection environment compensation method, detection signal confusion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is described in further detail below in conjunction with accompanying drawing:

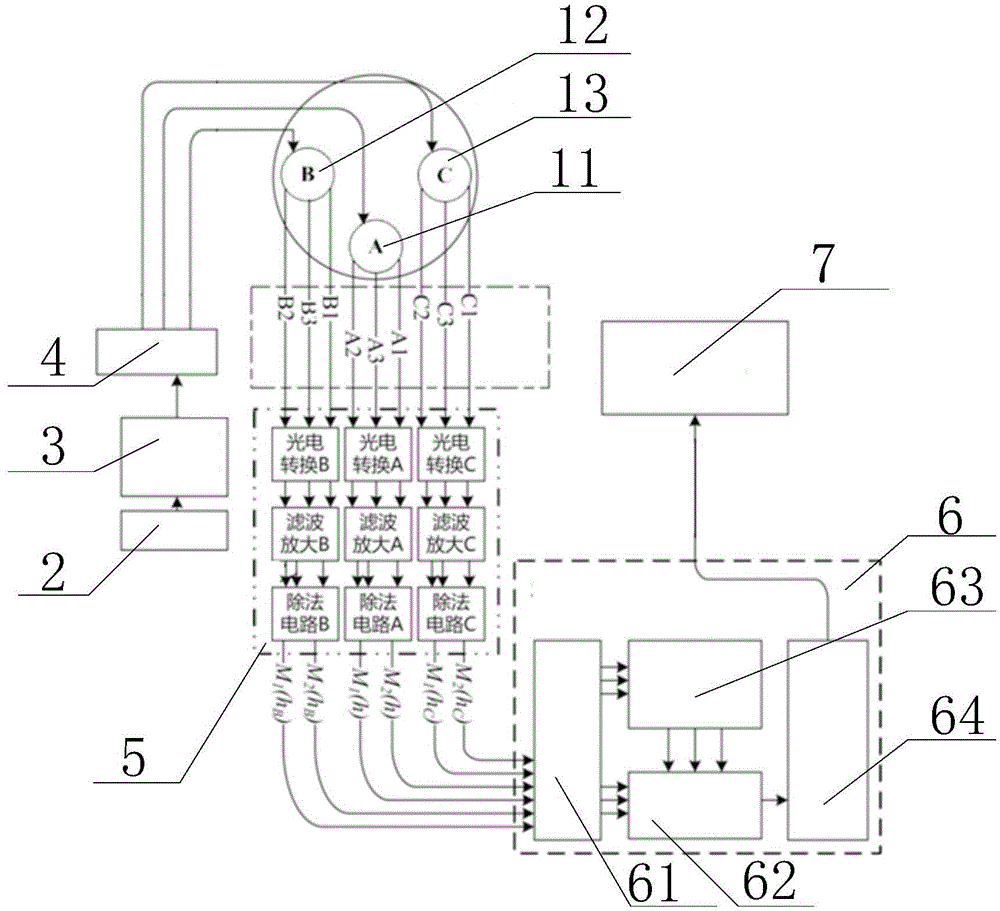

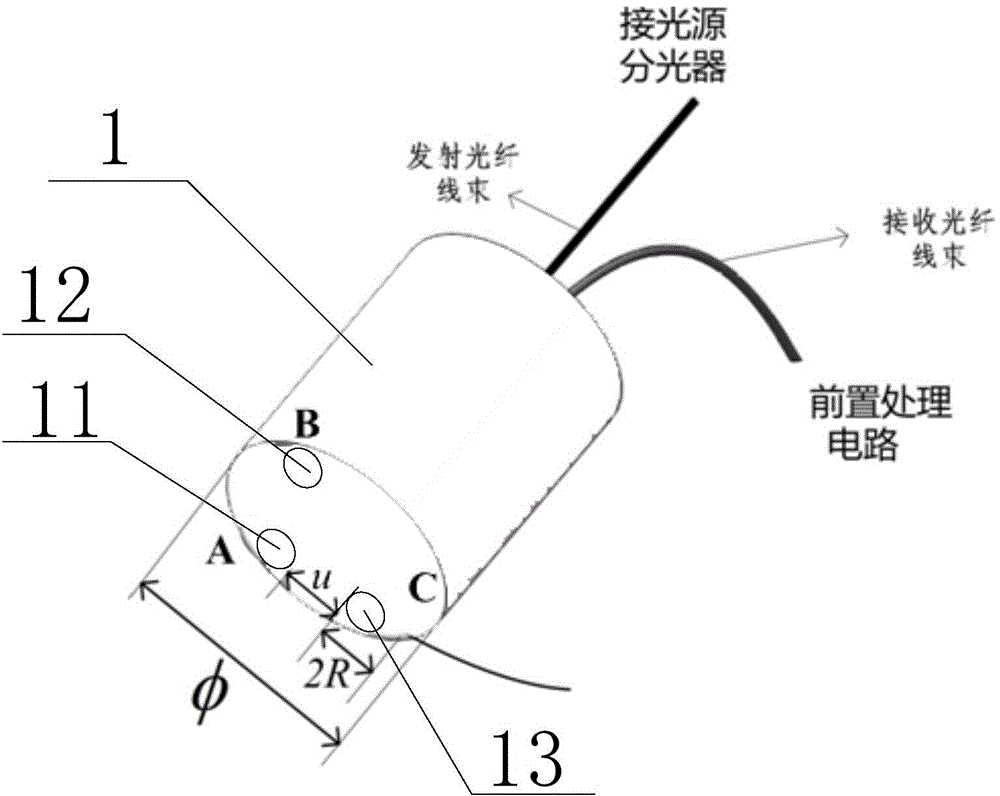

[0042] refer to figure 1 , figure 2 and image 3 The device for three-dimensional characterization and optical fiber dynamic detection of aeroengine tip clearances according to the present invention includes a laser light source 2, a pulse light source control circuit 3, a beam splitter 4, a three-dimensional sensing probe 1 for tip clearances, a preprocessing circuit 5, and a single-chip microcomputer 6 And host computer 7;

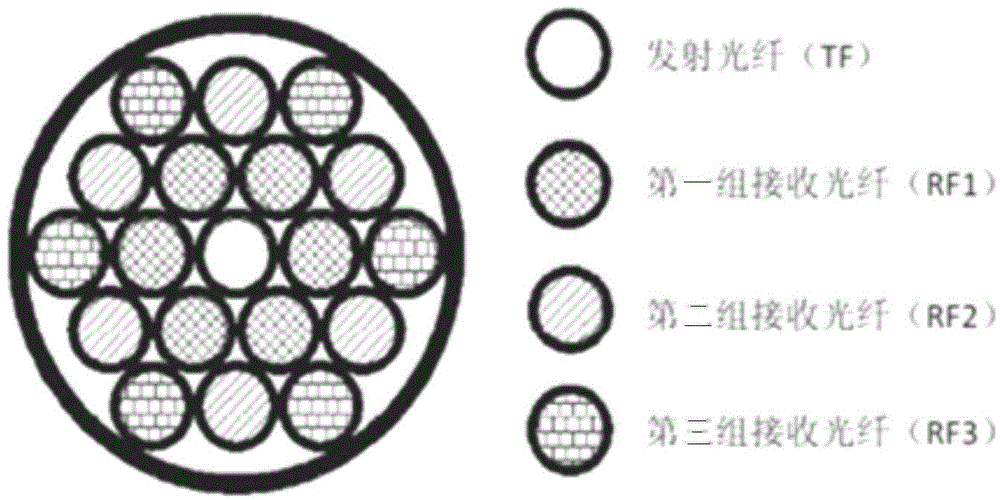

[0043] The blade gap three-dimensional sensing probe 1 includes a reference fiber unit 11, an axial angle measurement fiber unit 13 and a circumferential angle measurement fiber unit 12, the connection line between the reference fiber unit 11 and the circumference angle measurement fiber unit 12 and the reference fiber unit 11 and the axial angle measuring fiber unit 13 are perpendicular to each other, the reference fiber unit 11, the axial a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com