AlN ceramic substrate thermal insulation structure four-unit array gas sensor and manufacturing method thereof

A gas sensor and isolation structure technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of poor thermal stability, complex film forming process, silicon-based thermal mismatch, etc., to improve thermal stability and reduce thermal conduction loss. , The effect of reducing heating power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

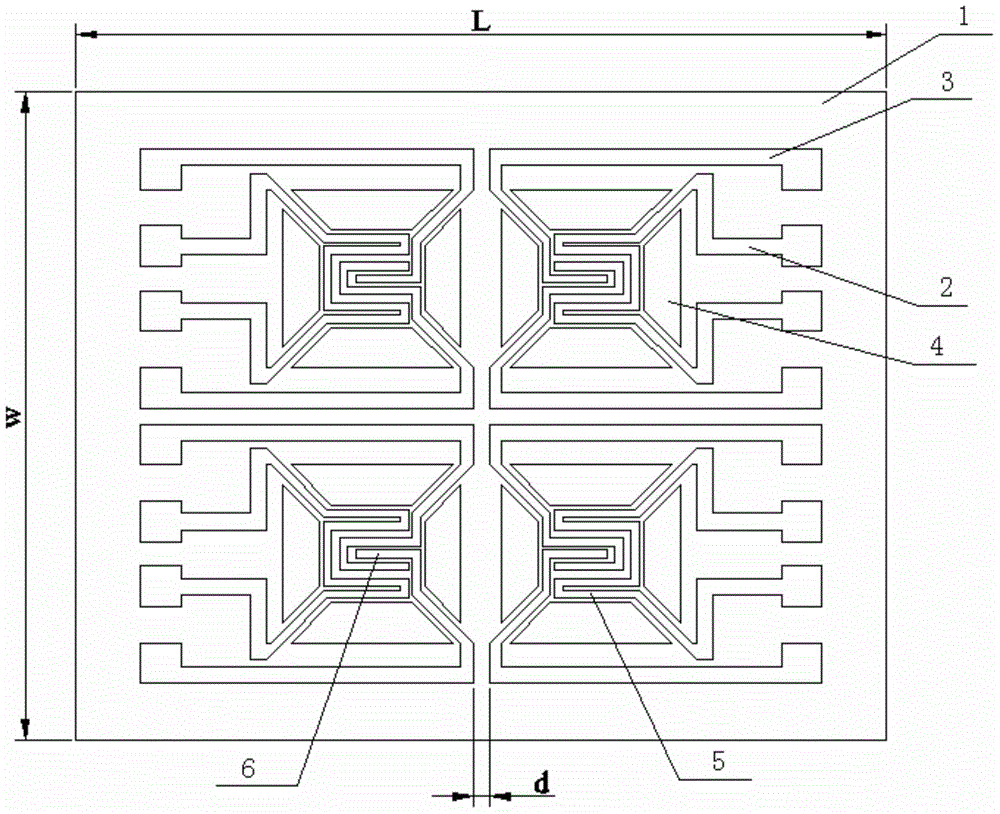

[0021] Specific implementation mode 1. Combination figure 1 , figure 2 , image 3 and Figure 4 Describe this embodiment mode, an AlN ceramic-based thermal isolation structure four-unit array gas sensor described in this embodiment mode, the sensor includes a rectangular aluminum nitride ceramic substrate 1 and four independent sensor units, the rectangular aluminum nitride ceramic The substrate 1 is divided into four parts along the two midlines of the rectangle by four independent sensor units, and the four independent sensor units are respectively arranged in the four parts; the main body of each independent sensor unit is rectangular, and the two independent sensors located above The units are arranged oppositely, and the two independent sensor units located below are arranged oppositely;

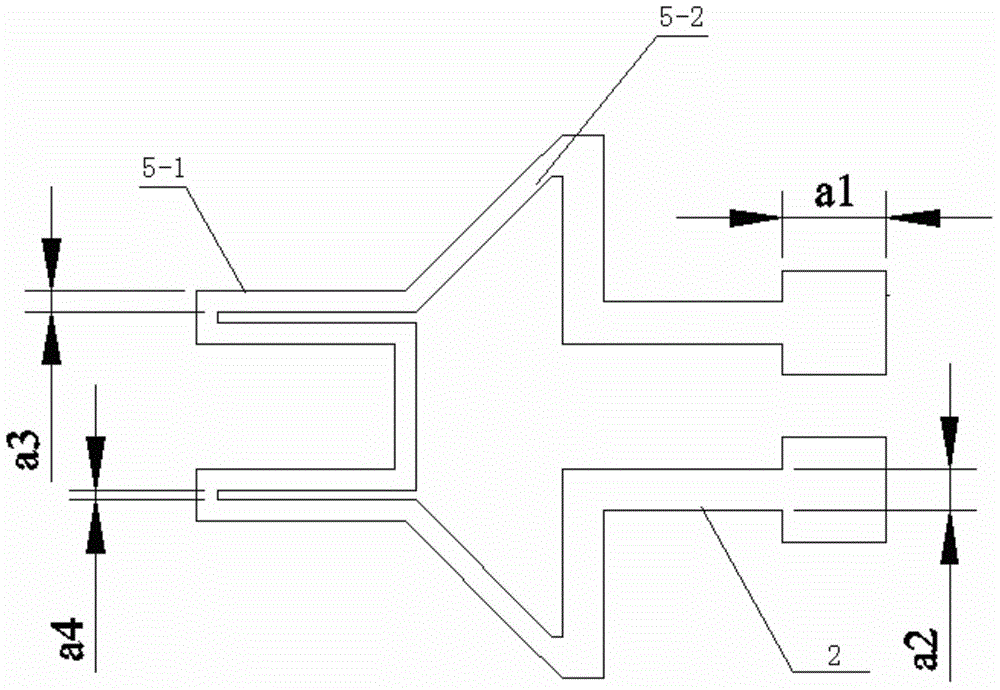

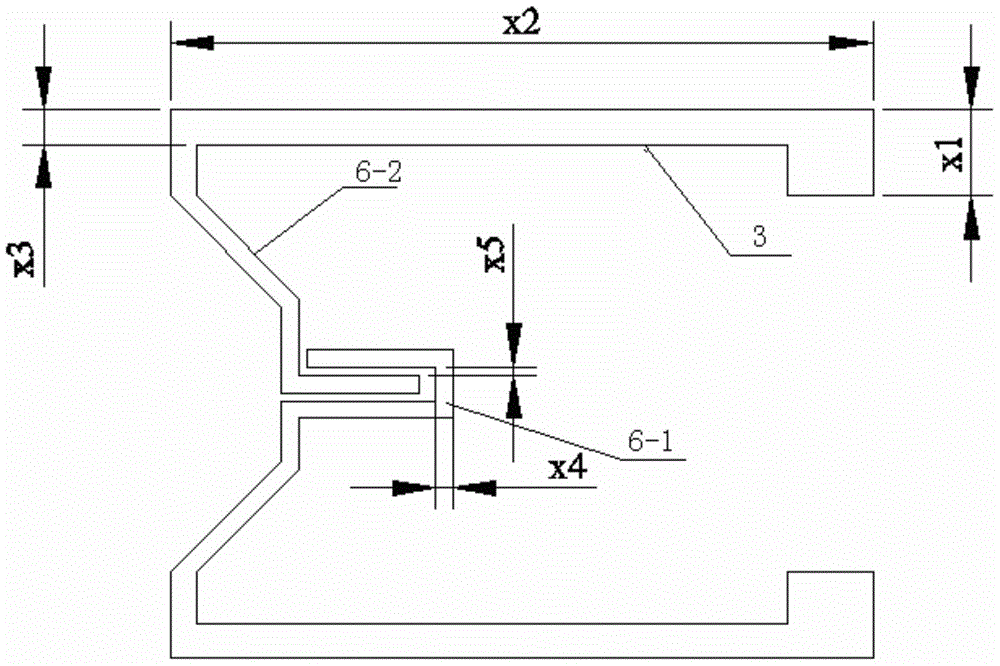

[0022] Each independent sensor unit includes two heating electrodes 2, two signal electrodes 3, four isosceles trapezoidal thermal isolation holes 4, a rectangular heater 5 and a si...

specific Embodiment approach 2

[0027] Specific Embodiment 2. This embodiment is a further description of a four-unit array gas sensor with an AlN ceramic base thermal isolation structure described in Specific Embodiment 1. The platinum film width a3 of the heater head 5-1 is 0.05mm-0.1 mm, the two heating electrodes 2 include electrode sheets and electrode leads, the electrode sheets are square, the side length a1 is 0.25mm-0.5mm, the platinum film width a2 of the electrode leads is 0.1mm-0.2mm, and the width of the peaks on both sides a4 is 0.025mm-0.05mm;

[0028]The platinum film width x4 of the two signal detection heads 6-1 of the signal detector 6 is 0.05mm-0.1mm, one of the two signal detection heads 6-1 is a rectangular opening, and the other is linear, and the linear The signal detection head is arranged in the opening rectangle number detection head, the linear signal detection head is parallel to the long side of the opening rectangle number detection head, and the distance x5 between the straigh...

specific Embodiment approach 3

[0030] Specific Embodiment 3. This embodiment is a further description of a four-element array gas sensor with an AlN ceramic-based thermal isolation structure described in Specific Embodiment 1. The thickness of the shaped aluminum nitride ceramic substrate 1 is 0.1mm-0.25mm , the length W of the short side is 4mm-8mm, and the length L of the long side is 5mm-10mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com