An optical interconnect substrate for use in spacecraft and military computers and its manufacturing method

A computer and spacecraft technology, applied in the field of optical interconnect substrate and its manufacturing, to reduce light wave absorption and scattering loss, meet the needs of high-speed data transmission, and easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

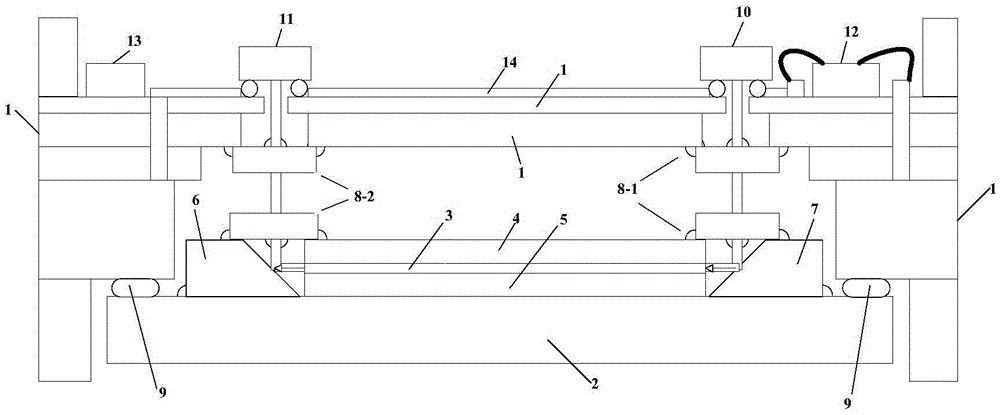

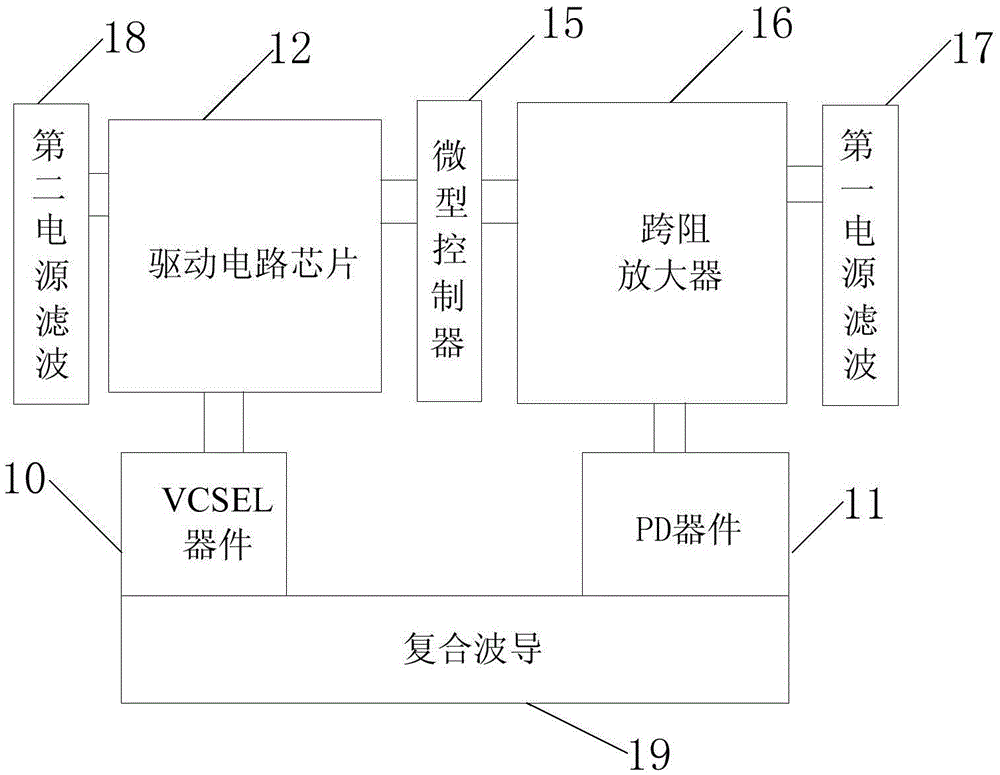

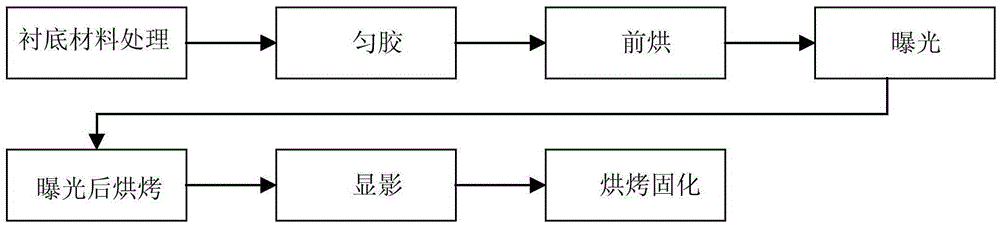

[0040] see figure 1 , an optical interconnection substrate for spacecraft and military computers, comprising a first reflector 7, a second reflector 6, a first microlens array 8-1, a second microlens array 8-2, and a launch assembly , a receiving component, a silicon wafer 2 polished on one side, and an LTCC substrate 1 with a cavity on one side, wherein the transmitting component integrates a VCSEL device 10, a VCSEL interface circuit board and a driving circuit chip 12; the receiving component integrates a PD device 11 , PD interface circuit board, drive circuit chip; The cavity of described LTCC substrate 1 is provided with the silicon wafer 2 of single-sided polishing, and the surface roughness of the polished surface of silicon wafer 2 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com