Method for preparing functionalized composite nano-fiber modified electrode

A technology of composite nanofibers and modified electrodes, which is applied in the direction of electrochemical variables of materials, material analysis by electromagnetic means, and measurement devices, etc. Related literature reports and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

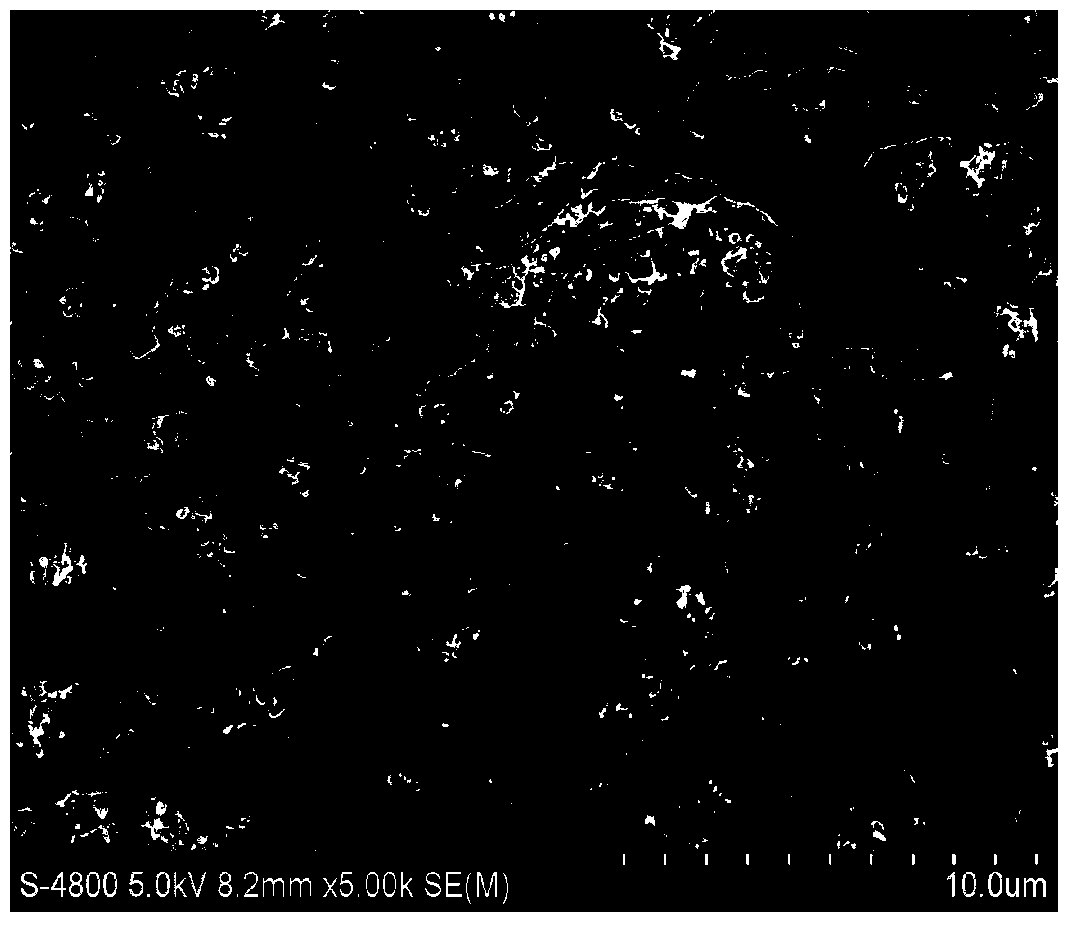

[0048] The microscopic morphology of PA6-MWNTs and PA6-MWNTs-PTH were characterized respectively. From the field emission scanning electron microscopy (FESEM) of PA6-MWNTs ( figure 1 , figure 2 ) It can be seen that the random orientation of PA6-MWNTs forms a nanofiber membrane with a porous 3D structure. After electropolymerization of thionine PTH on PA6-MWNTs nanofibers ( image 3 , Figure 4 ), the diameter of the nanofibers becomes significantly thicker, ranging from 100 nm to 500 nm in diameter. It can be seen from the enlarged map that the surface of the nanofiber is no longer smooth, and the surface is obviously covered with a film. From the comparison of the microscopic morphology of nanofibers before and after electropolymerization of thionine, it can be concluded that a layer of thionine has been successfully electropolymerized on the surface of nanofibers.

[0049] The bare glassy carbon electrode (GC) and the composite nanofiber modified electrode (PA6-MWNTs / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com