A full-color electrochromic display

A technology of electrochromic and electrochromic materials, applied in the direction of color-changing fluorescent materials, instruments, chemical instruments and methods, etc., can solve the problems of insufficient colorful display, slow response speed and poor stability of electrochromic displays, and achieve faster response. Speed, solve the lack of colorful display, solve the effect of poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

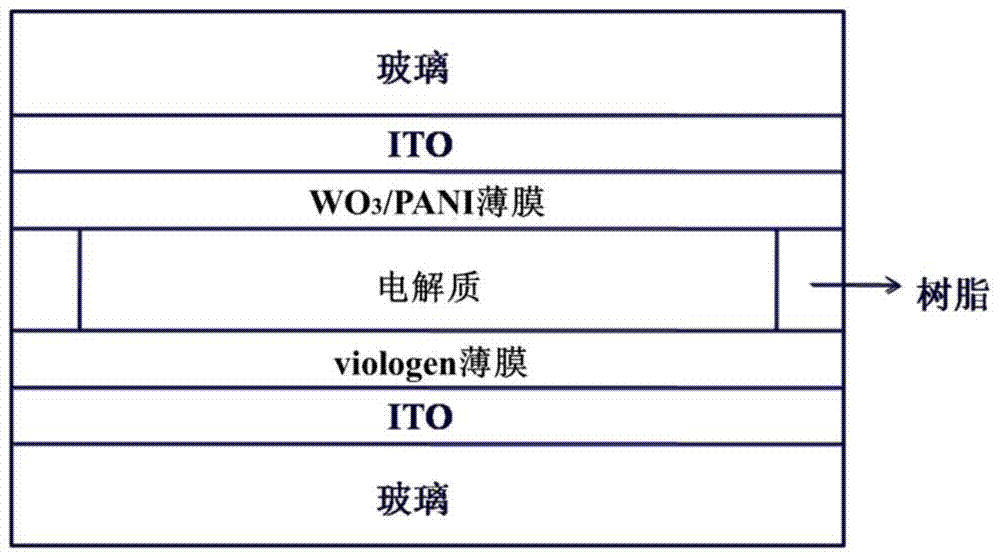

[0035] The method for preparing a full chromatogram display by utilizing an electrochromic material is implemented according to the following steps:

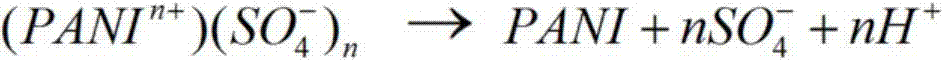

[0036] (1) Mix 10mL of 0.01M sulfuric acid and 0.01mL of aniline, add ultra-pure water to 30mL, then add 10mL of 0.01M sodium tungstate and mix well as electrolyte. Using step voltage method (-0.6V and 0.6V each for 10s, cycle 3 times), using sodium tungstate as tungsten source, decompressed aniline as monomer, using three-electrode system, ITO as working electrode, platinum sheet As the counter electrode and Ag / AgCl as the reference electrode, a laminated WO3 / PANI film was prepared.

[0037] (2) Using methyl viologen as a raw material, a 0.1 mol / L solution was prepared, spin-coated twice at a speed of 500 r / min, and dried naturally to obtain a viologen film.

[0038] (3) On the basis of using propylene carbonate (PC) as an organic solvent and lithium perchlorate (LiClO4) as a lithium salt, prepare a 0.1mol / L LiClO4 / PC solution...

Embodiment 2

[0041] The method for preparing a full chromatogram display by utilizing an electrochromic material is implemented according to the following steps:

[0042] (1) Mix 10mL of 0.1M sulfuric acid and 0.2mL of aniline, add ultra-pure water to 30mL, then add 10mL of 0.1M sodium tungstate and mix well as electrolyte. Using step voltage method (-0.7V and 0.7V each for 20s, cycle 6 times), using sodium tungstate as tungsten source, decompressed aniline as monomer, using three-electrode system, ITO as working electrode, platinum sheet As the counter electrode and Ag / AgCl as the reference electrode, a laminated WO3 / PANI thin film was prepared.

[0043] (2) Using methyl viologen as a raw material, a 0.5 mol / L solution was prepared, spin-coated three times at a speed of 1000 r / min, and dried naturally to obtain a viologen film.

[0044] (3) On the basis of using propylene carbonate (PC) as an organic solvent and lithium perchlorate (LiClO4) as a lithium salt, prepare a 0.5mol / L LiClO4 / PC...

Embodiment 3

[0047] The method for preparing a full chromatogram display by utilizing an electrochromic material is implemented according to the following steps:

[0048] (1) Mix 10mL of 1M sulfuric acid and 0.5mL of aniline, add ultrapure water to 30mL, then add 10mL of 1M sodium tungstate to it and mix well as electrolyte. Using step voltage method (-0.8V and 0.8V each for 30s, cycle 10 times), using sodium tungstate as tungsten source, decompressed aniline as monomer, using three-electrode system, ITO as working electrode, platinum sheet As the counter electrode and Ag / AgCl as the reference electrode, a laminated WO3 / PANI thin film was prepared.

[0049] (2) Using methyl viologen as a raw material, a 1mol / L solution was prepared, spin-coated 4 times at a speed of 2000r / min, and dried naturally to obtain a viologen film.

[0050] (3) On the basis of using propylene carbonate (PC) as an organic solvent and lithium perchlorate (LiClO4) as a lithium salt, prepare a 1mol / L LiClO4 / PC solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com