Surface porous implant with bioactivity

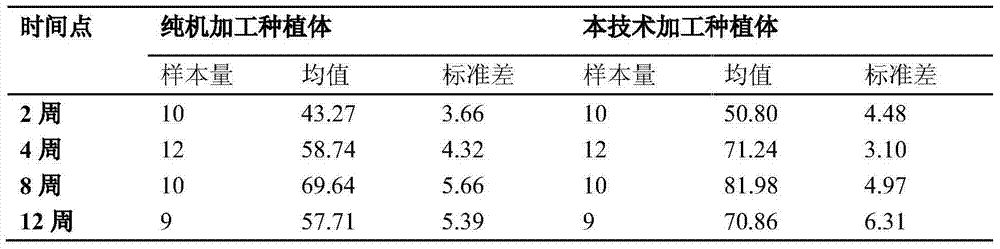

A bioactive, porous surface technology, applied in the field of medical bioimplantation materials, can solve the problems of low mechanical strength, assembly accuracy that cannot meet actual needs, and high manufacturing costs, so as to improve bioactivity, accelerate bone deposition, and reduce manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

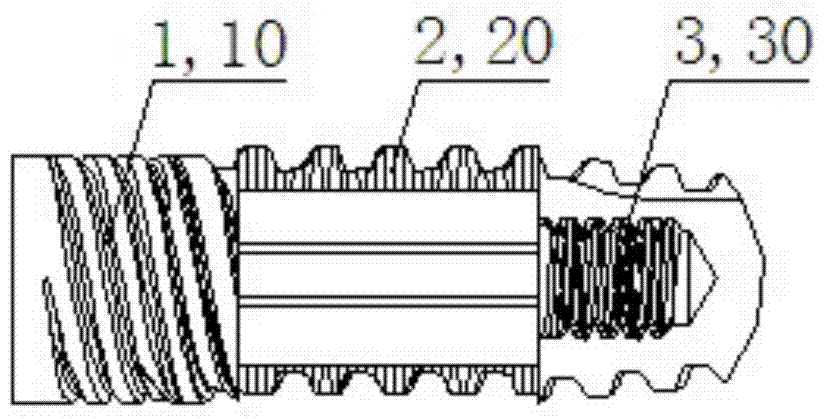

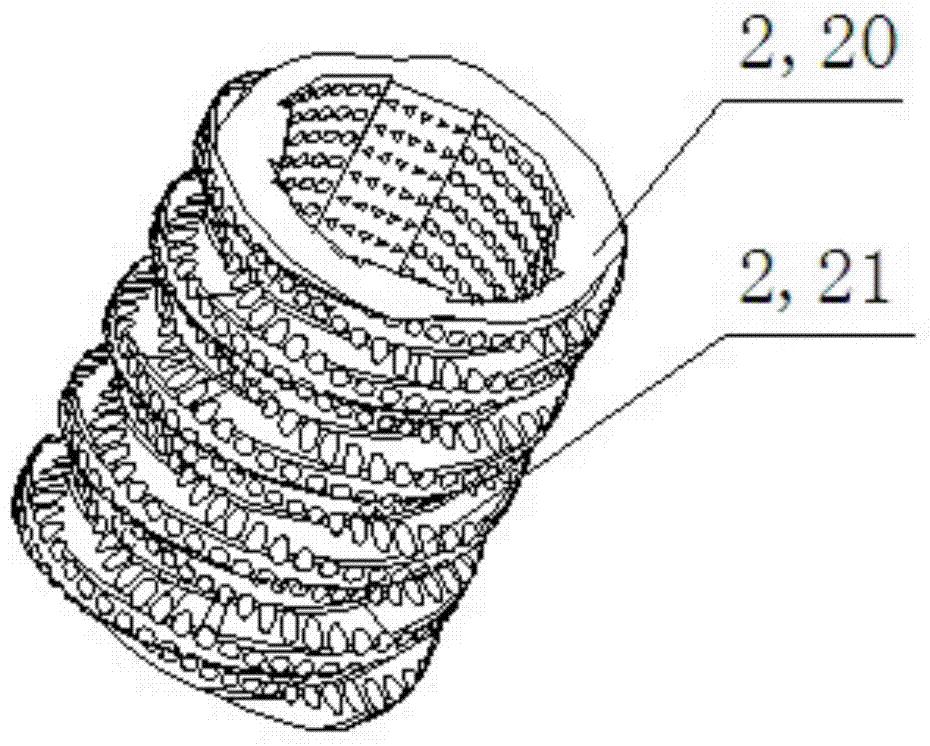

[0017] The steps of processing the implant of Φ3.3mm×10mm are as follows: the length of the threaded section 10 is 4mm, the length of the connecting screw is 6mm, the length of the porous sleeve 20 is 4mm, the length of the bolt structure 30 is 2mm, and the length of the threaded section is determined according to the actual length of the implant is 4mm, but the length of the porous sleeve 20 needs to be determined according to the length of the processed implant, so the length of the bolt structure 30 is 2mm; the diameter of the through hole 21 is 100 microns, the distance between the hole center diameters is 150 microns, and the particle size of the titanium powder is 10-30 microns, the inert gas is nitrogen, the scanning speed is 1m / s, and the spot diameter is 20 microns; the head 1, middle part 2, and tail part 3 are fixedly connected by square limit bolts; then the obtained Φ3.3mm×10mm The sandblasting pressure for the surface treatment of the combination is 0.3bar, the pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com