Preparation method for high-strength hydrogel filtering membrane

A technology of hydrogel and filtration membrane, which is applied in the field of preparation of high-strength hydrogel filtration membrane and can solve the problems of low mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A method for preparing a high-strength hydrogel filtration membrane, the specific implementation method is:

[0025] (1) Mix and dissolve the first monomer and the photoinitiator in deionized water to obtain the first monomer solution. The first monomer is one of 2-acrylamide-2-methylpropanesulfonic acid (AMPS), sodium p-styrenesulfonate (NaSS), and β-hydroxyethyl methacrylate (HEMA), with a concentration of 10~ 200 grams per liter (g / L); the photoinitiator is α-ketoglutaric acid (α-KG), 2-hydroxy-2-methyl-1-phenyl-propan-1-one (Darocur 1173), 2 -One of hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone (Irgacure2959), the concentration is 1~20g / L;

[0026] (2) Mixing and dissolving the second monomer, photoinitiator, and crosslinking agent in deionized water to obtain a second monomer solution. The second monomer is one of acrylamide (AAm), acrylic acid (AAc), and isopropylacrylamide (NIPAAm), with a concentration of 10-200g / L; the photoinitiator is α-KG, Darocur 117...

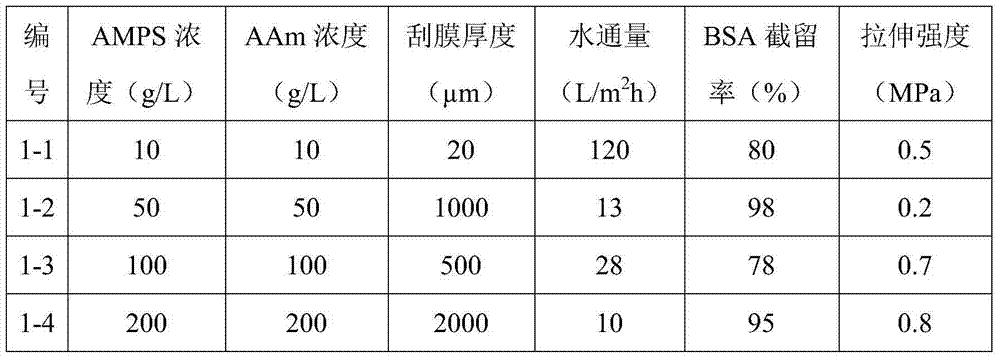

Embodiment 1

[0038] (1) According to the concentration requirements in Table 1, mix and dissolve AMPS and α-KG in deionized water to obtain an AMPS solution, wherein the concentration of α-KG is 1g / L; (2) mix AAm, α-KG according to the concentration requirements of the corresponding numbers -KG and MBAA are mixed and dissolved in deionized water to obtain an AAm solution, the concentration of α-KG is 1g / L, and the concentration of MBAA is 1g / L; (3) the AMPS solution is irradiated under ultraviolet light, and the irradiation dose is 5× 10 3 J / m 2 , initiate AMPS polymerization, obtain prepolymer; (4) prepolymer, α-KG, SiO 2 Mix evenly, the mass percentage of each component is: prepolymer 60%, α-KG 1%, SiO 2 (5) scrape the casting solution through a film forming machine to obtain a liquid film with a thickness of 20-2000 μm, and irradiate and cross-link under ultraviolet light, and the irradiation dose is 5×10 3 J / m 2 , to obtain the first network film; (6) soak the first network film in...

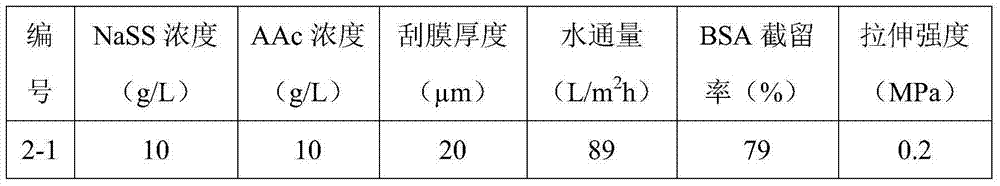

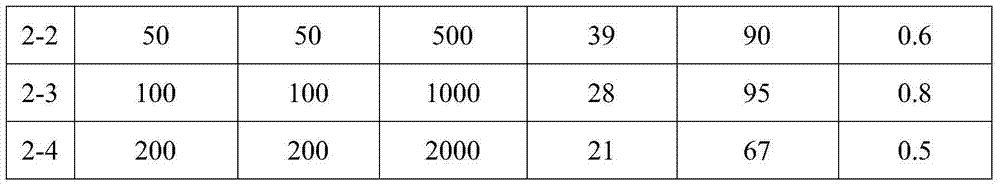

Embodiment 2

[0042] (1) Mix and dissolve NaSS and Darocur 1173 in deionized water according to the concentration requirements in Table 2 to obtain a NaSS solution. The concentration of Darocur 1173 is 20g / L; (2) AAc, Darocur 1173, DVB Mix and dissolve in deionized water to obtain AAc solution, the concentration of Darocur 1173 is 20g / L, and the concentration of DVB is 20g / L; (3) NaSS solution is irradiated under ultraviolet light, and the irradiation dose is 5×10 4 J / m 2 , initiate NaSS polymerization, obtain prepolymer; (4) prepolymer, Darocur 1173 are uniformly mixed, and the mass percent of each component is: prepolymer 95%, Darocur 1173 is 5%, obtains casting solution; (5 ) scrape the cast film solution through a film forming machine to obtain a liquid film with a thickness of 20-2000 μm, irradiate and cross-link under ultraviolet light, and the irradiation dose is 5×10 4 J / m 2 , to obtain the first network film; (6) soak the first network film in the AAc solution for 20 hours, take ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com