Solid heterogeneous catalyst for hydroformylation of olefins, preparation method and application thereof

A heterogeneous catalyst, olefin hydroformyl technology, applied in the direction of carbon monoxide reaction preparation, organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, etc., can solve the problem of unsatisfactory reaction results and achieve high Stability, broad industrial prospects, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

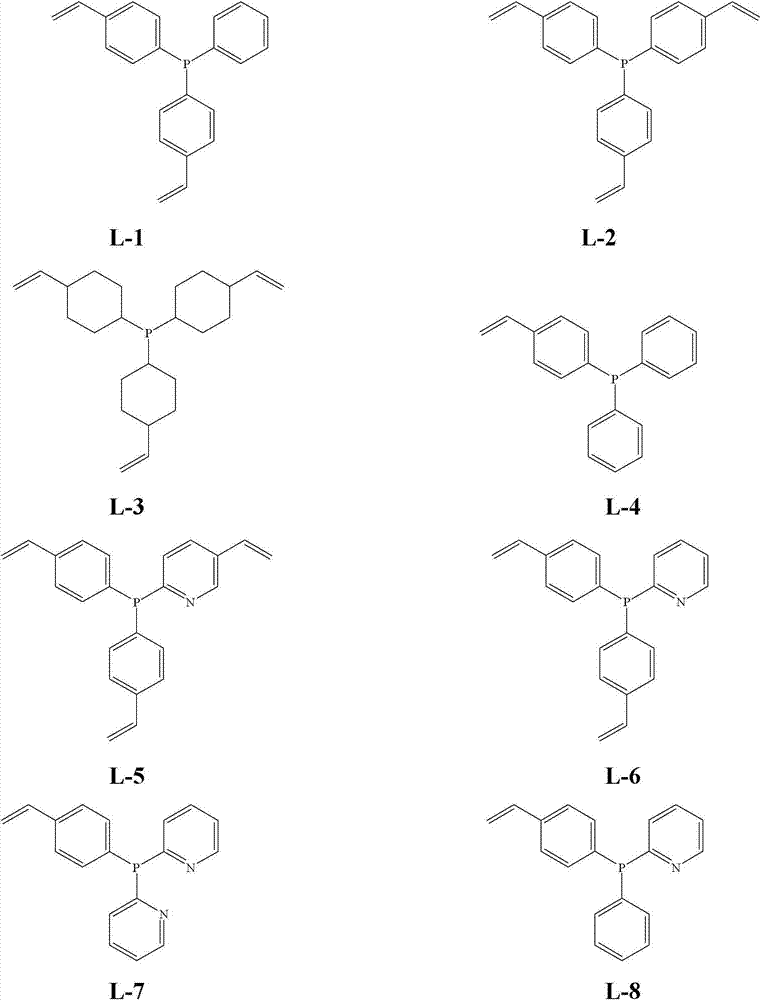

[0050] Embodiment 1: Preparation of organic ligand polymer

[0051] Under 298K and a nitrogen gas protection atmosphere, 10.0 grams of tris (4-vinylphenyl) phosphine was dissolved in 100.0 ml of tetrahydrofuran solvent, and 1.0 grams of free radical initiator azobisisobutyronitrile was added to the above solution, and stirred for 2 hours . The stirred solution was allowed to stand at 373K under a nitrogen atmosphere for 24h. After the above-mentioned standing solution is cooled to room temperature, the solvent is vacuumed off at room temperature (about 298K), and the tris(4-vinylphenyl)ylphosphine is polymerized by solvothermal method to obtain a compound containing P ligand polymer. The three (4-vinylphenyl) phosphine ligand polymer carrier polymerization technical route in the present embodiment is as follows:

[0052]

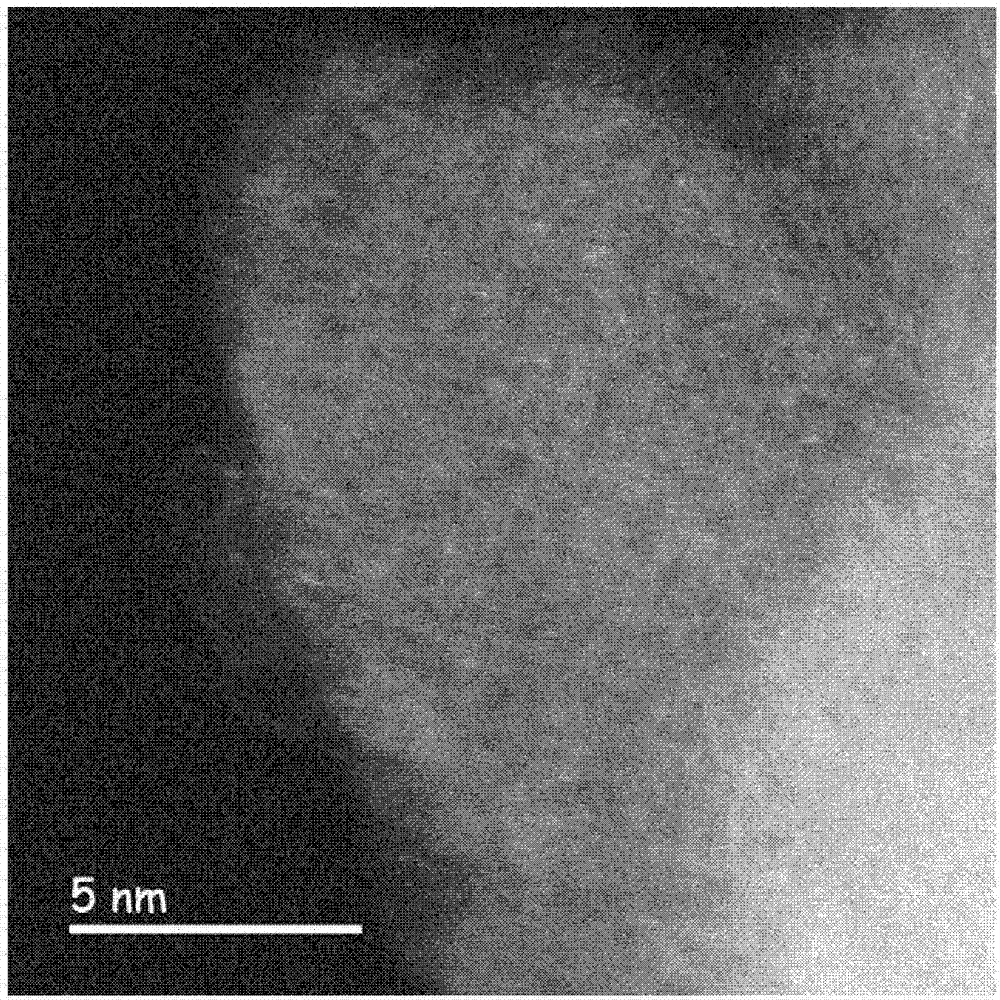

[0053] Among them, the degree of polymerization n is 450-550, with a hierarchical pore structure including macropores, mesopores and micropores, and t...

Embodiment 2

[0054] Embodiment 2: Preparation of organic ligand polymer

[0055] The preparation process is the same as in Example 1, except that bis(4-vinylphenyl)-2-pyridylphosphine monomer is used instead of tris(4-vinylphenyl)phosphine monomer.

Embodiment 3

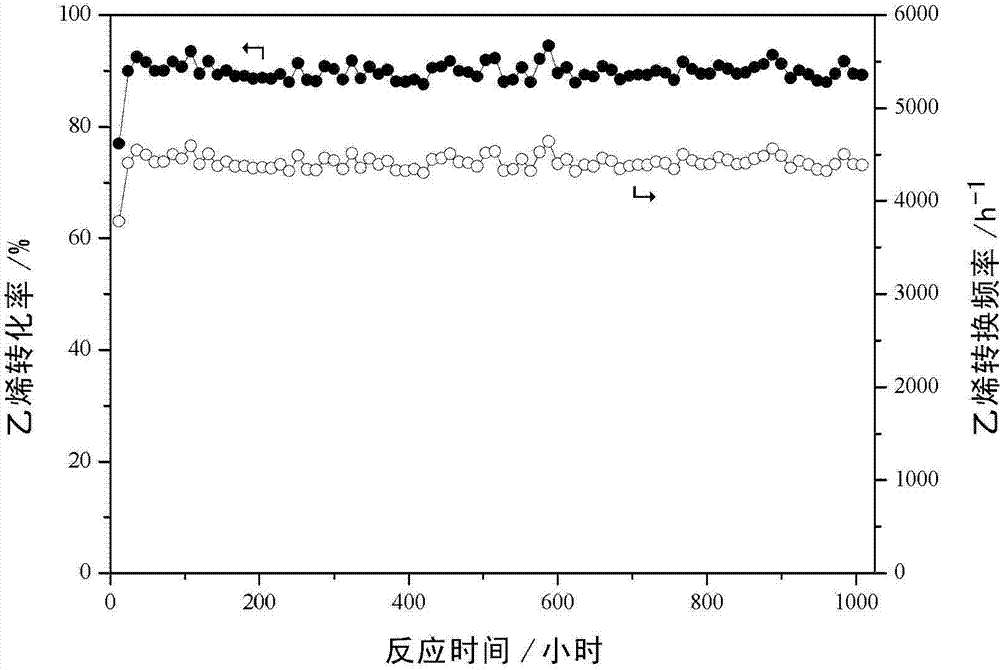

[0056] Embodiment 3: preparation of solid heterogeneous catalyst containing 2wt%Rh

[0057] Under 298K and a nitrogen gas protection atmosphere, 50.10 mg of rhodium acetylacetonate dicarbonyl (I) was added to a three-necked flask filled with 100.0 ml of tetrahydrofuran solvent, stirred and dissolved, and 1.0 gram of the multi-level pore compound prepared in Example 1 was added. structure of the P ligand-containing polymer, the mixture was stirred at 298K and nitrogen gas protection atmosphere for 24 hours, and then the solvent was vacuumed off at room temperature, and the P-ligand-containing polymer with a hierarchical porous structure was obtained. Solid Heterogeneous Catalysts from Supported Metal Rh. The above prepared solid heterogeneous catalyst consisting of tri(4-vinylphenyl) phosphine polymer self-supporting metal component with hierarchical pore structure is loaded into a fixed bed reactor, and the molar ratio of 1:2 is passed through Ethylene gas and CO / H as olefin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com