On-line self-cleaning method for vacuum ultraviolet lamp

A vacuum ultraviolet lamp, self-cleaning technology, applied in the direction of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc. The effect of reducing manual workload, simplifying operation and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

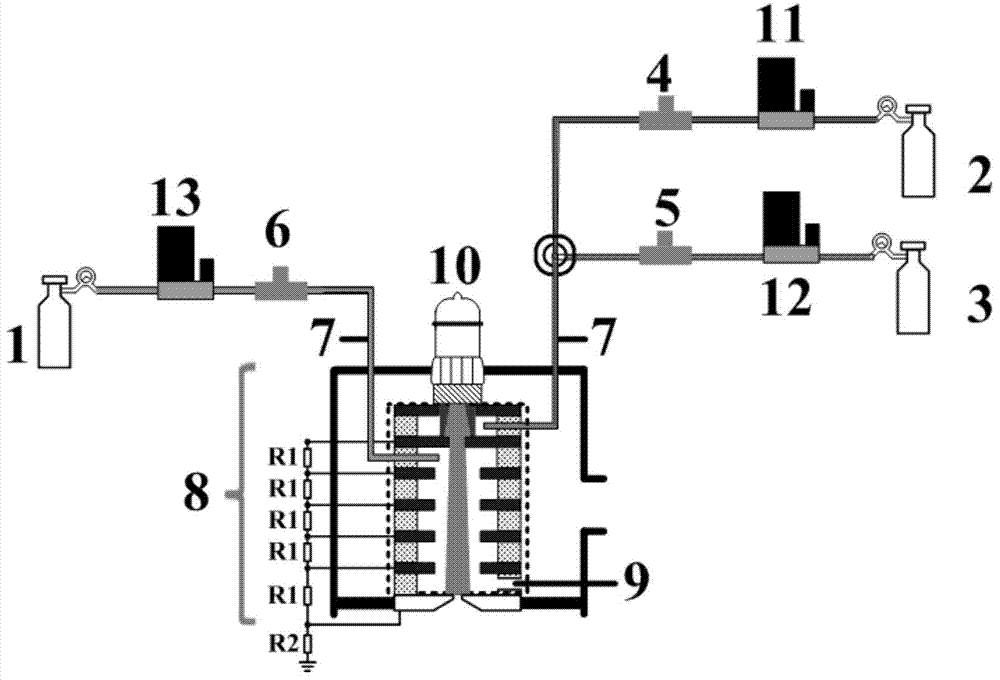

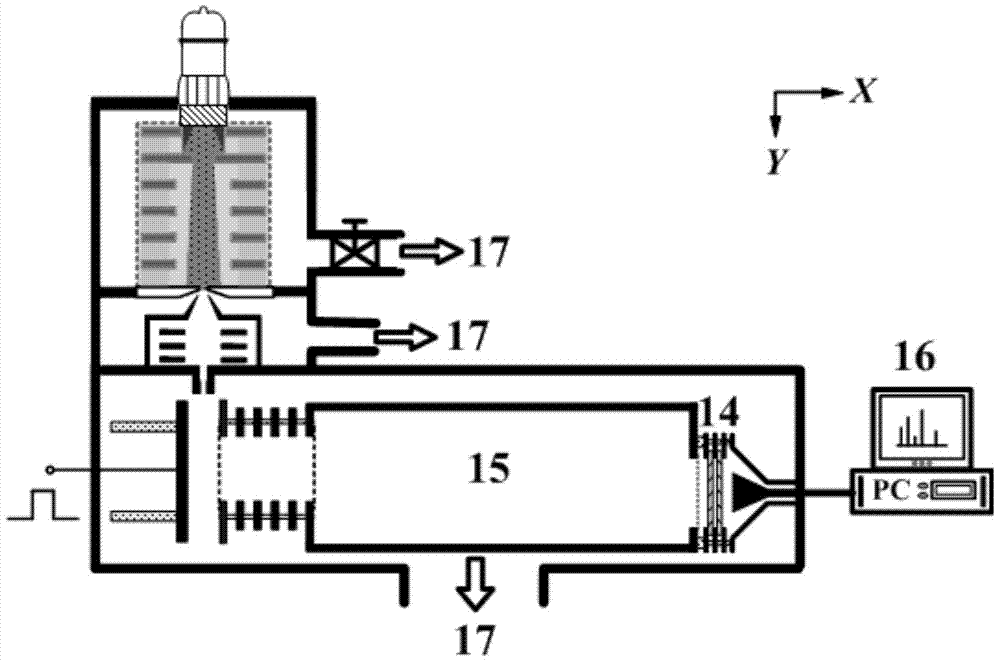

Method used

Image

Examples

Embodiment 1

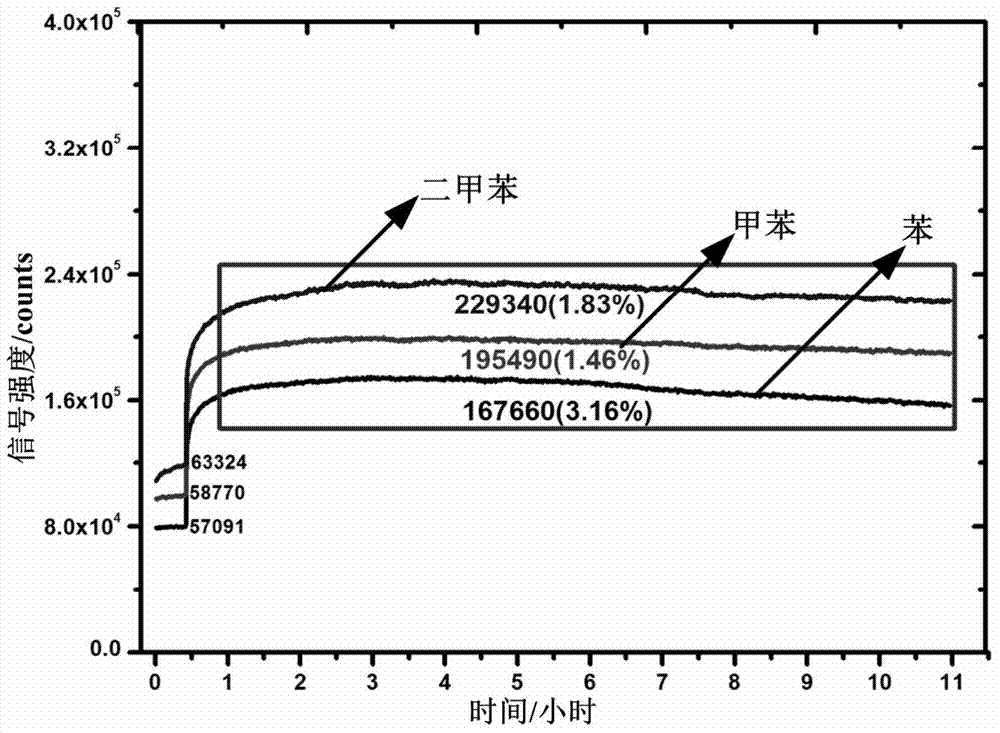

[0036] Aiming at the examination of the performance of the online self-cleaning method of a vacuum ultraviolet lamp described in the present invention, the experiment uses 100ppmv mixed gas of benzene, toluene and xylene as the sample gas, and uses a single photon ionization time-of-flight mass spectrometer to test. Set the flow rate of nitrogen-hydrogen mixture to 30mL / min, the flow rate of high-purity nitrogen to 500ml / min, and the flow rate of benzene, toluene and xylene to 50ml / min. The ionization method of the ionization source in the experiment adopts the vacuum ultraviolet single photon ionization (VUV-SPI) ionization method, and the air pressure in the ionization area is maintained at about 40.8Pa. Firstly, sampling is carried out under high-purity nitrogen and hydrogen, and the sampling time of each point is 30s, and several points are collected continuously, which are used as the comparison signal intensity. Afterwards, nitrogen-hydrogen mixed gas was introduced to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com