Measuring device and measuring method for argon tungsten-arc welding arc force

A technology of argon tungsten arc welding and measuring device, which is applied in the field of arc, can solve the problems of arc influence and cannot reflect the interaction relationship, etc., and achieves the effect of avoiding electromagnetic field interference, real measurement results, and improving limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

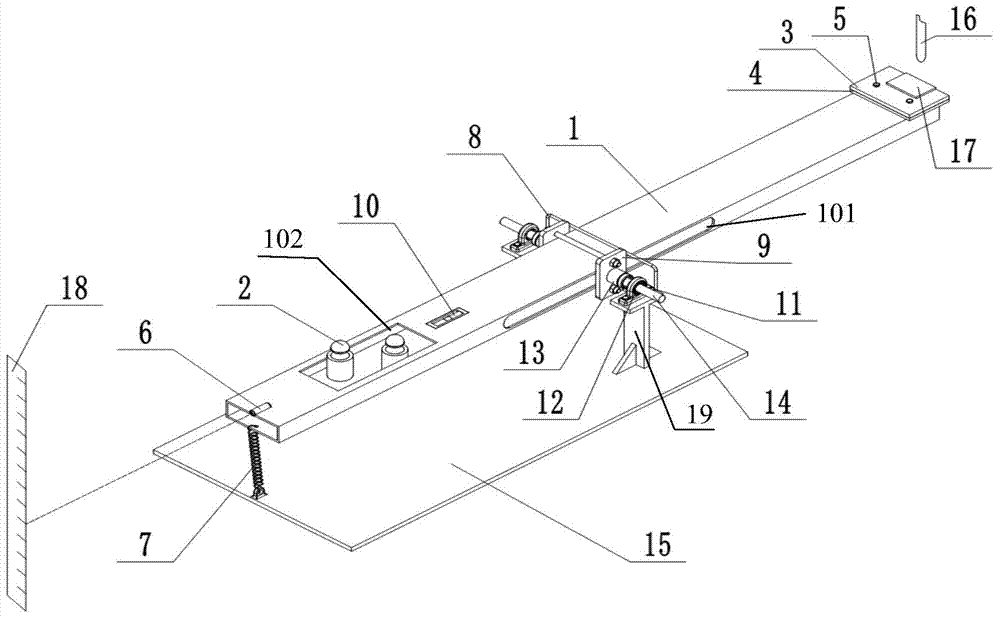

[0044] Example 1 Welding arc force test of argon tungsten arc welding

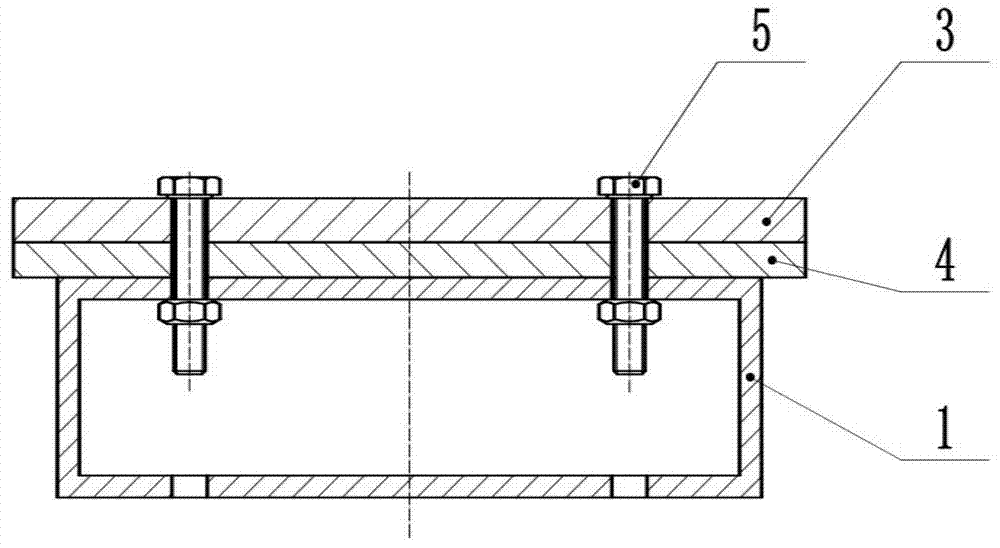

[0045] The test supporting plate 3 is made of Q235 steel plate, the welding parameters of argon tungsten arc welding are shown in Table 1, and the elastic stiffness of the spring 7 is selected as 0.1N / mm.

[0046] Table 1 Welding parameters of argon tungsten arc welding

[0047] Welding current

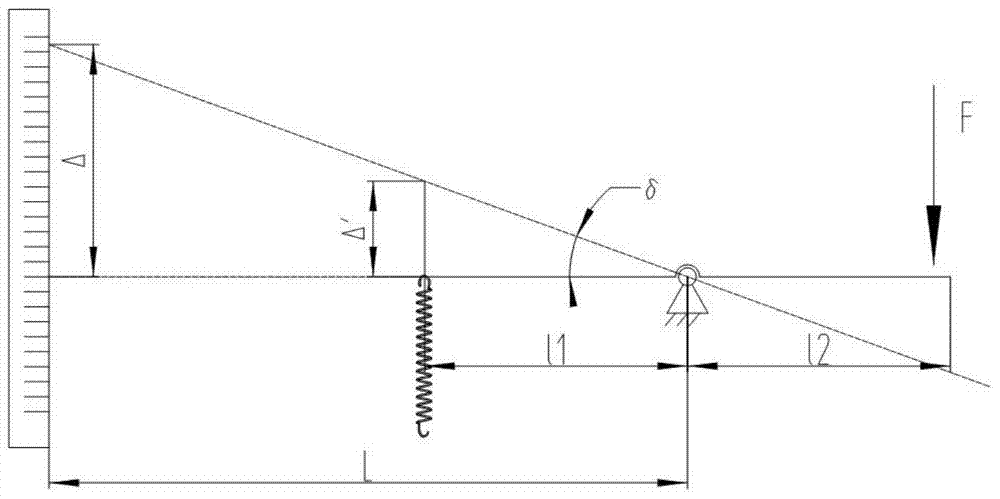

[0048] The distance L between the scale 18 and the axis of the bearing rod 14 is 3m. Place the test block 17 on the pallet 3, add a weight (counterweight 2) in the counterweight groove 102 and adjust the relative position between the slideway 101 and the linear bearing 13 to bring the balance board 1 to a balanced state, and measure l 1 300mm, l 2 is 600mm. Record the reading A on scale 18 at this time 1 It is 153mm. Turn on the argon tungsten arc welding power supply, adjust the welding parameters for welding. Start reading when the cross laser on the scale 18 tends to be stable, and record the ...

Embodiment 2

[0049] The test supporting plate 3 is made of Q235 steel plate, the welding parameters of argon tungsten arc welding are shown in Table 1, and the elastic stiffness of the spring 7 is selected as 0.1N / mm. The main component of the active agent is TiO 2 ,Cr 2 o 3 ,ZrO 2 and CaF 2 Wait. Before the test, the active agent powder was mixed into a solution with acetone, and then evenly coated on the support plate 3 with a flat brush, and the uniformity of the coating was ensured as much as possible during the coating process. In the test L, l 1 , l 2 All unchanged, the device is in a balanced state by the counterweight 2. The initial reading A on the scale 18 at this time 1 It is 153mm. Turn on the argon tungsten arc welding power supply, adjust the welding parameters for welding. Start reading when the cross laser on the scale 18 becomes stable, and record the reading A at this time 2 It is 224mm. From tanδ=(Δ) / L, tanδ=Δ′ / l 1, The variation Δ' of the spring is obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic stiffness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com