Method for preparing lithium ion battery negative electrode material lithium titanate

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of high energy consumption in the preparation of high-energy ball milling, difficulty in large-scale industrialization, and difficult control of product morphology. Good electrochemical performance, easy industrial production, and moderate conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Slowly drop a lithium oxalate solution with a lithium ion concentration of 0.5 to 1 mol / L into tetrabutyl titanate, so that the molar ratio of Li to Ti in the emulsion is: n(Li / Ti)=0.75:1, Stir thoroughly to obtain an emulsion;

[0022] 2) put the emulsion into an oven for reaction, the temperature of the oven is 80°C, and after 12 hours, the product that has become solid is taken out from the oven;

[0023] 3) After grinding the product, heat treatment is carried out at 600° C. for 3 hours to obtain the final product.

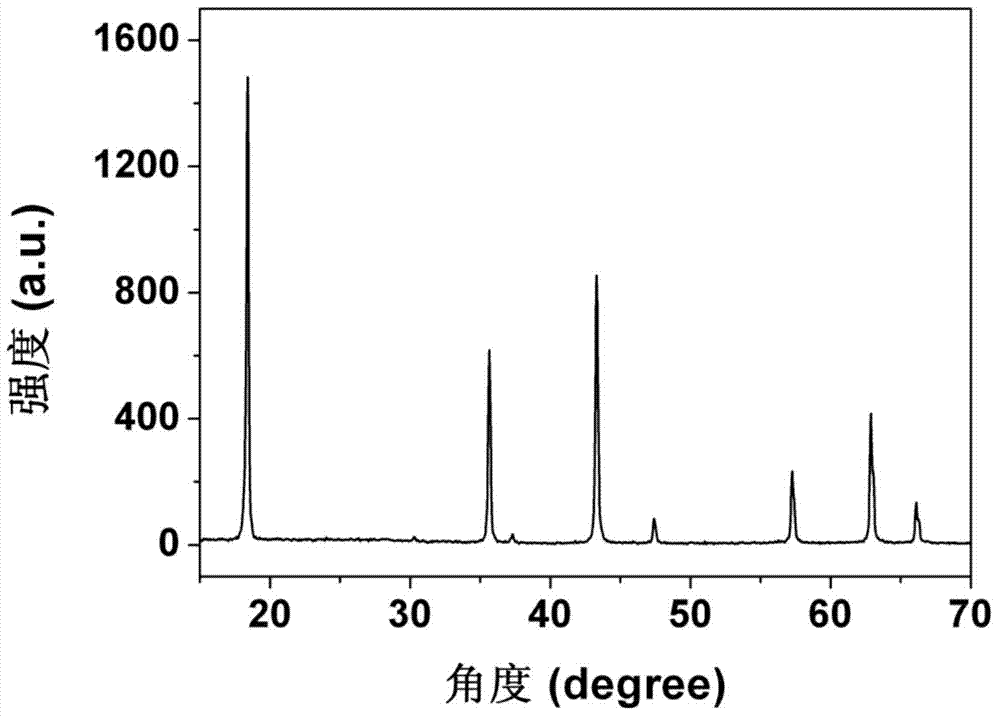

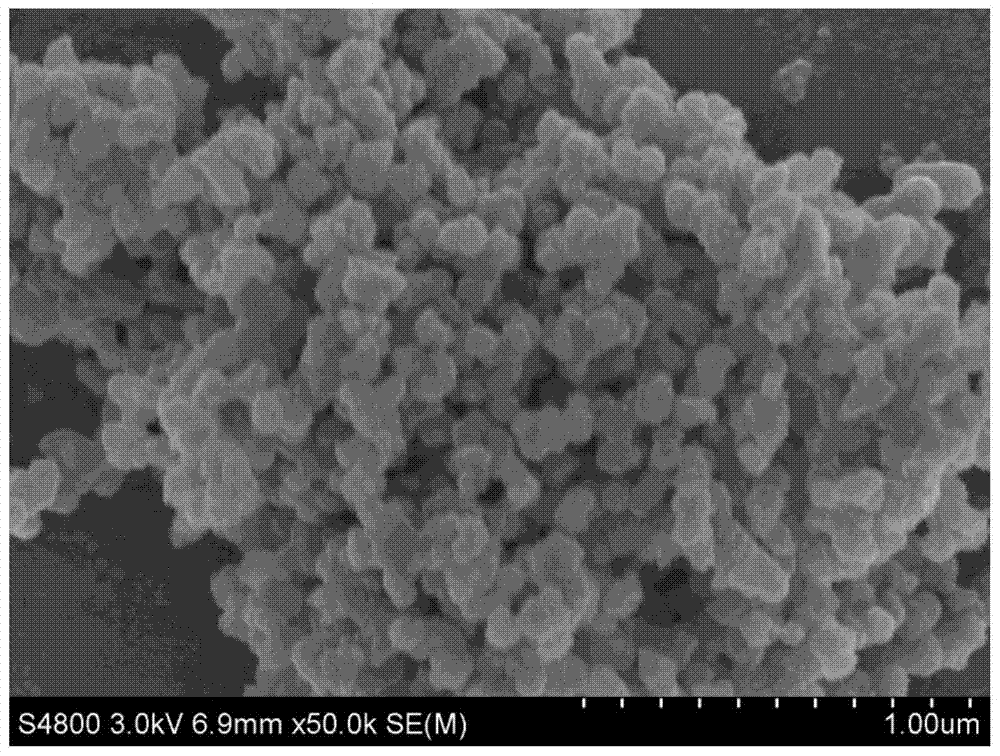

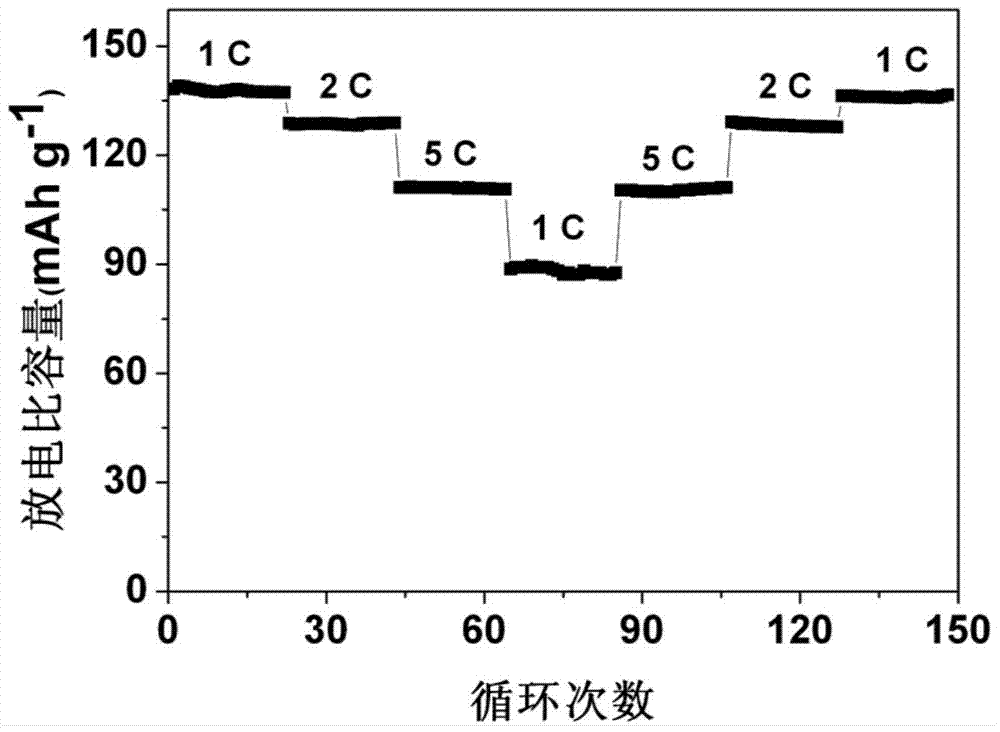

[0024] see Figure 1~3 ,From figure 1 It can be seen that the diffraction peaks of the prepared product are very sharp and have high intensity, and there are no other impurity phases, indicating that the product is a pure phase lithium titanate. From figure 2 It can be seen that the prepared lithium titanate is nano-scale small particles and presents a loose structure. The electrode material of this type of structure is conducive to the intercal...

Embodiment 2

[0026] 1) Slowly drop a lithium ion concentration of 2 to 4mol / L lithium acetate solution into tetrabutyl titanate, so that the molar ratio of Li to Ti in the emulsion is: n(Li / Ti)=0.85:1, fully Stir to make an emulsion;

[0027] 2) put the emulsion into an oven for reaction, the temperature of the oven is 70°C, and after 5 hours, the product that has become solid is taken out from the oven;

[0028] 3) After the product is ground, it is heat-treated at 1000° C. for 8 hours to obtain the final product.

Embodiment 3

[0030] 1) Slowly drop a lithium hydroxide solution with a lithium ion concentration of 1 to 4mol / L into tetrabutyl titanate, so that the molar ratio of Li to Ti in the emulsion is: n(Li / Ti)=1.2:1, Stir thoroughly to obtain an emulsion;

[0031] 2) put the emulsion into an oven for reaction, the temperature of the oven is 100°C, and after 8 hours, the product that has become solid is taken out from the oven;

[0032] 3) After the product is ground, it is heat-treated at 800° C. for 6 hours to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com