Method for olefin hydroformylation reaction through adopting solid heterogeneous catalyst

A technology for olefin hydroformyl and heterogeneous catalysts, applied in the directions of carbon monoxide reaction preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of inability to meet industrialized production, complicated catalyst preparation process, poor catalyst stability, etc., Achieve the effect of solving the loss of metal components, broad industrial application prospects and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

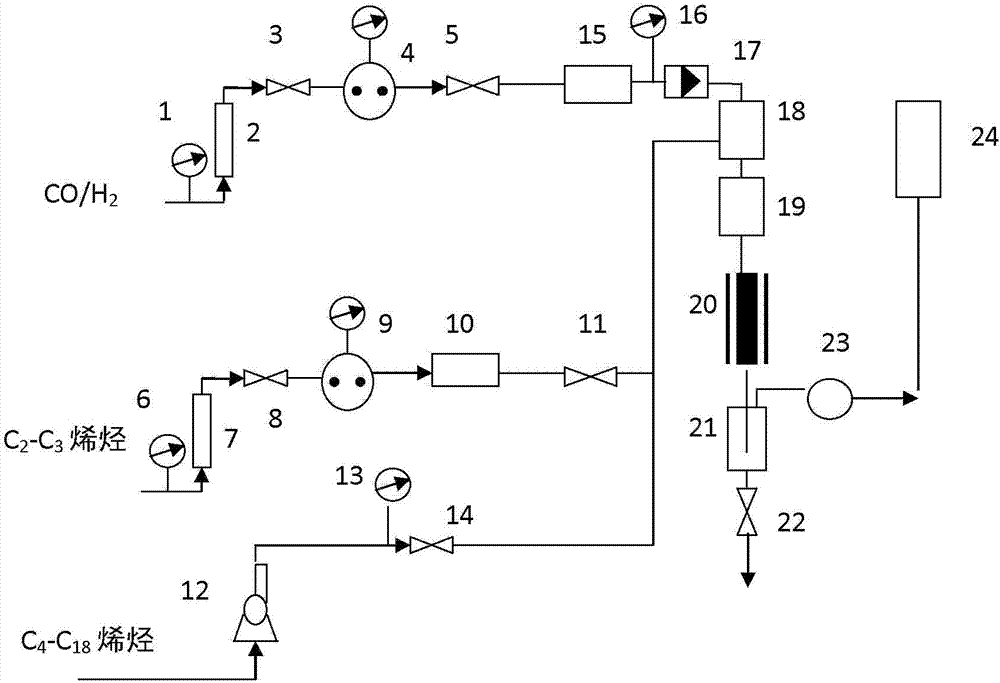

Method used

Image

Examples

Embodiment 1

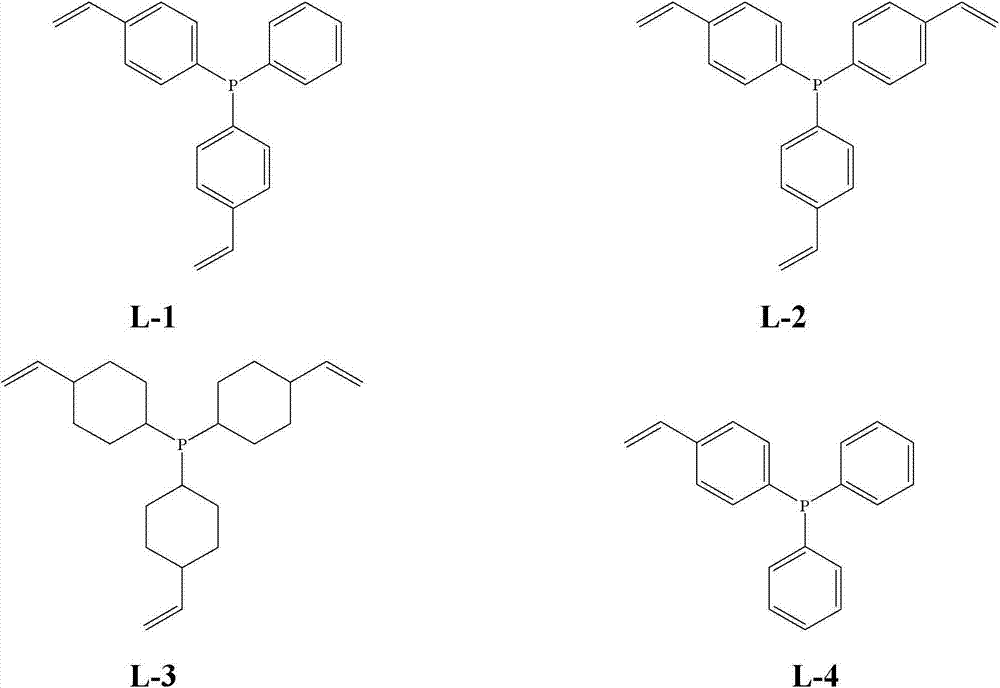

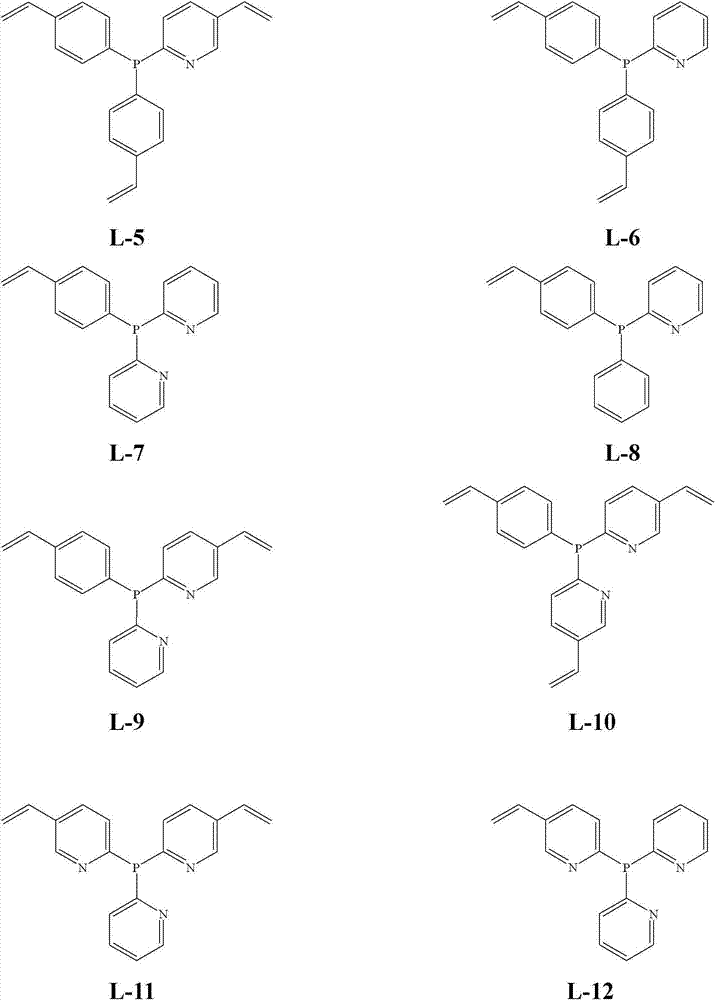

[0055] Under 298K and a nitrogen gas protection atmosphere, 10.0 grams of tris (4-vinylphenyl) phosphine was dissolved in 100.0 ml of tetrahydrofuran solvent, and 1.0 grams of free radical initiator azobisisobutyronitrile was added to the above solution, and stirred for 2 hours . The stirred solution was allowed to stand at 373K under a nitrogen atmosphere for 24h. After the above-mentioned standing solution is cooled to room temperature, the solvent is vacuumed off at room temperature (about 298K), and the tris(4-vinylphenyl)ylphosphine is polymerized by solvothermal method to obtain a compound containing P ligand polymer. The three (4-vinylphenyl) phosphine ligand polymer carrier polymerization technical route in the present embodiment is as follows:

[0056]

[0057] Among them, the degree of polymerization n is 450-550, with a hierarchical pore structure including macropores, mesopores and micropores, and the measured BET specific surface area is 981m 2 / g, the pore ...

Embodiment 2

[0060] Refer to Example 1 for the synthesis of tris(4-vinylphenyl)phosphine ligand polymer carrier. Under 298K and a nitrogen gas protection atmosphere, take 0.5 mg of acetylacetonate dicarbonyl rhodium (I), join in a three-necked flask filled with 100.0 ml of tetrahydrofuran solvent, stir and dissolve, add 1.0 g of the above-mentioned preparation with a hierarchical porous structure The P-ligand-containing polymer, the mixture was stirred at 298K and nitrogen gas protection atmosphere for 24 hours, and then the solvent was vacuumed off at room temperature, and the self-supported P-ligand polymer with a hierarchical porous structure was obtained. Metallic Rh as solid heterogeneous catalysts. Add the solid heterogeneous catalyst of the metal Rh self-supported by the P ligand-containing polymer with a hierarchical porous structure prepared above into the fixed-bed reactor, and feed ethylene gas as the olefin raw material with a molar ratio of 1:2 and CO / H 2 Mixed gas (wherein ...

Embodiment 3

[0062] Refer to Example 1 for the synthesis of tris(4-vinylphenyl)phosphine ligand polymer carrier. Under 298K and a nitrogen gas protection atmosphere, get 12.53 mg of acetylacetonate dicarbonyl rhodium (I) and join in a three-necked flask filled with 100.0 ml of tetrahydrofuran solvent, stir and dissolve, add 1.0 g of the above-mentioned prepared rhodium with hierarchical pore structure P ligand-containing polymer, the mixture was stirred at 298K and a nitrogen gas protection atmosphere for 24 hours, and then the solvent was vacuumed off at room temperature to obtain a self-supported P-ligand polymer with a hierarchical pore structure. Solid heterogeneous catalysts for metallic Rh. Add the solid heterogeneous catalyst prepared above into a fixed-bed reactor, and feed propylene gas and CO / H 2 Mixed gas (wherein H 2 :CO volume ratio=1:1), at 393K, 1.0MPa, the olefin gas volume space velocity is 1000h -1 , CO / H 2 The volume space velocity of the mixed gas is 2000h -1 condi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com