Wafer repetitive lithography defect inspection and analysis method, system and wafer production method

A defect inspection and analysis method technology, which is applied in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve problems such as easy missed or false detection, and difficult to effectively detect repetitive lithography defects on wafers. Achieve the effect of avoiding missed or false detection, reducing the risk of shipment, and high convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

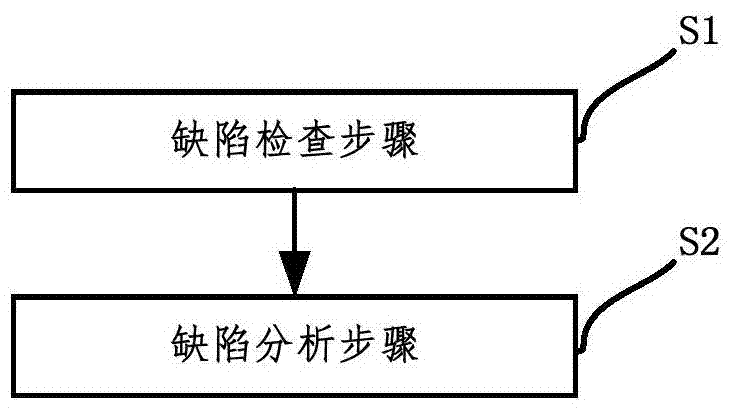

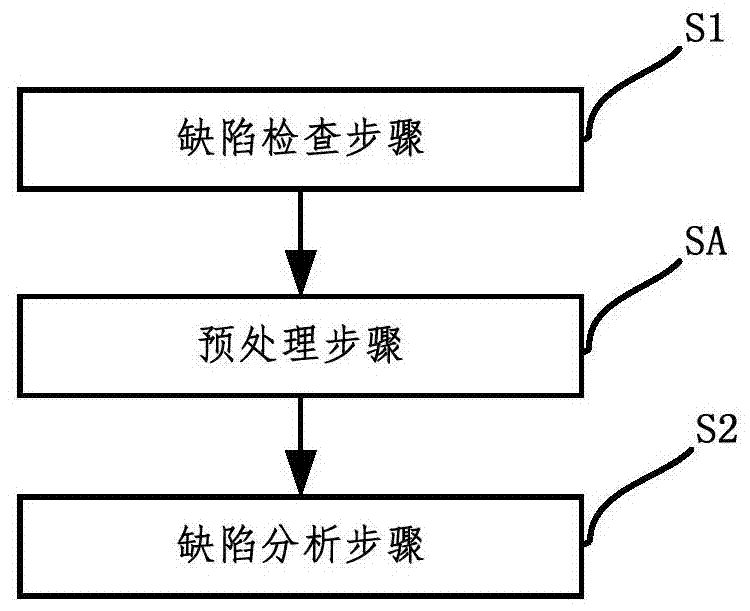

[0059] like figure 1 As shown, this example provides a wafer repetitive lithography defect inspection and analysis method, including the following steps:

[0060] S1. Defect inspection step: after the lithography process of a certain batch of wafers is completed, N wafers are selected from the batch of wafers, and the defects on the selected wafers are scanned in full to obtain the Defect information of the selected wafer; the defect information includes position information and size information of the defect;

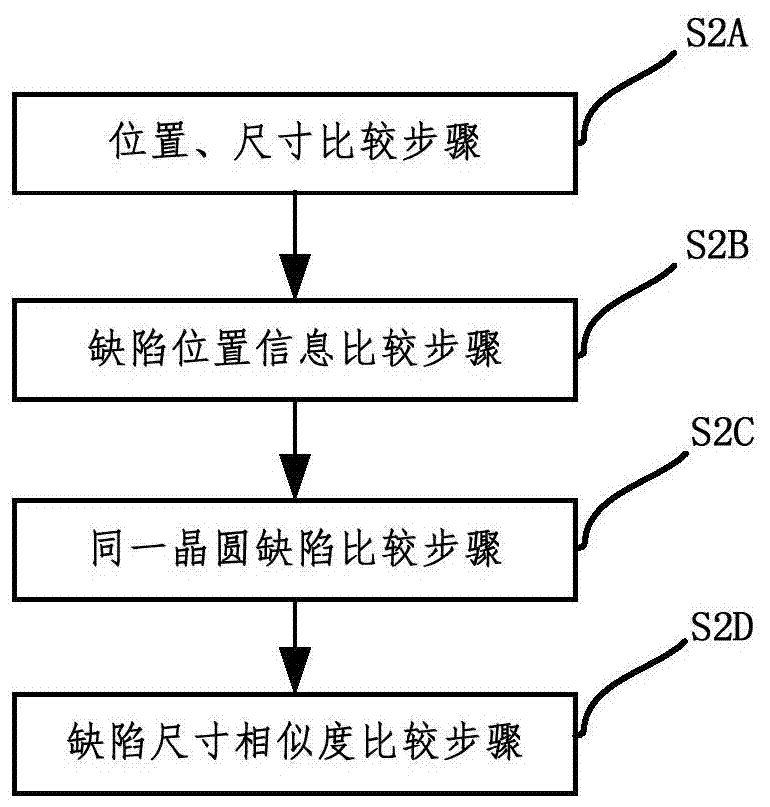

[0061] S2, defect analysis step: compare the position information and size information of the selected wafer defects;

[0062] If there are defects with consistent position information and size information on the selected wafers, it is determined that the batch of wafers has repetitive lithography defects in the lithography process;

[0063] If there is no defect with consistent position information on the selected wafers, it is determined that the batch of wafers ha...

Embodiment 2

[0100] This example provides a wafer production method, which includes the following steps: after a certain batch of wafers is finished with a lithography process, repetitive lithography defect inspection and analysis are performed on the wafers;

[0101] If there are no repetitive lithography defects, continue to follow-up production;

[0102] If there is a repetitive lithography defect, the product will be processed according to abnormal production, the lithography process will be suspended, and the production will continue after eliminating the repetitive lithography defect;

[0103] Wherein, the "repetitive lithography defect inspection and analysis on it" is implemented by the wafer repetitive lithography defect inspection and analysis method provided in Embodiment 1 above.

[0104] Most of the above-mentioned wafer production methods are known to those skilled in the art. The improvement of the present invention only improves the repetitive lithography defect inspection ...

Embodiment 3

[0107] This example provides a wafer repetitive lithography defect inspection and analysis system, such as Figure 7 As shown, it includes the following modules:

[0108] The defect inspection module 1 is used to select N wafers from the batch of wafers after the lithography process of a certain batch of wafers is completed, and scan the whole wafers for defects on the selected wafers to obtain the described defect information of the selected wafer; the defect information includes the position information and size information of the defect;

[0109] Defect analysis module 2, for comparing the position information and size information of the selected wafer defects;

[0110] If there are defects with consistent position information and size information on the selected wafers, it is determined that the batch of wafers has repetitive lithography defects in the lithography process;

[0111] If there is no defect with consistent position information on the selected wafers, it is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com