Garbage classification equipment and garbage classification method based on chemical element properties as well as application

A chemical element and garbage sorting technology, applied in the direction of solid waste removal, etc., can solve the problems of increasing dioxin/furan toxic gas, occupying land resources, boiler corrosion, etc., and achieve simplification, automation and intelligence of garbage sorting operation High degree, the effect of reducing the content of chlorine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

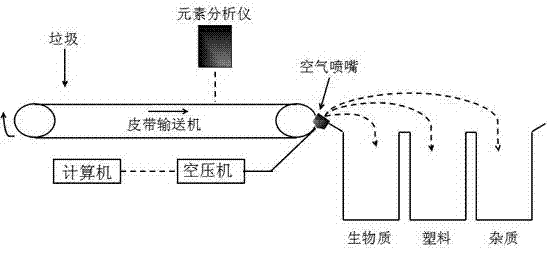

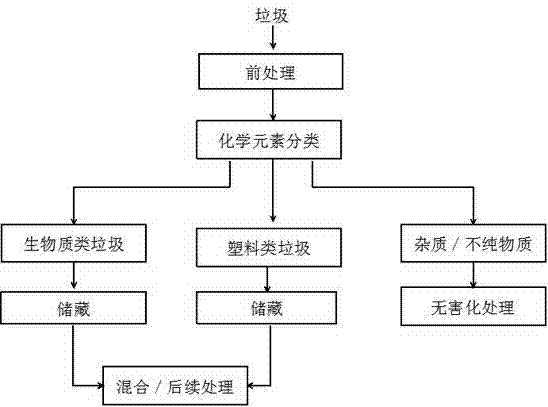

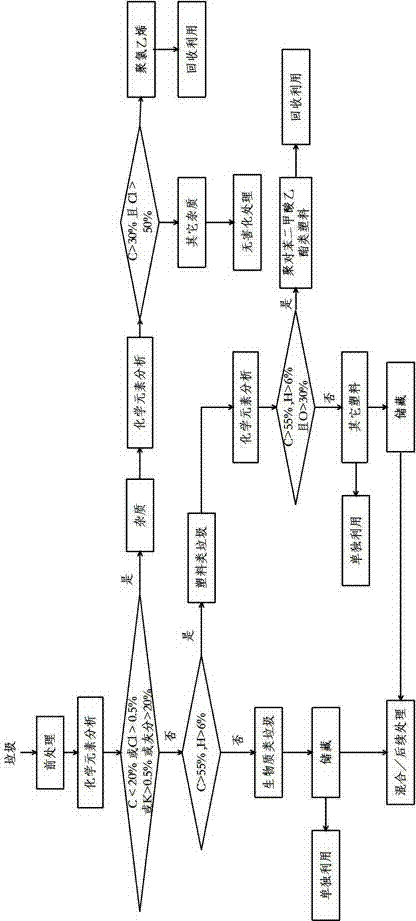

[0038] Such as image 3 As shown, the garbage is subjected to pretreatment such as bag breaking, crushing and screening, and the pretreated garbage mixture is placed on the belt conveyor, and the online real-time detection chemical element analyzer located above the belt conveyor is used to analyze the garbage. Detection and analysis, when the chemical element analyzer detects C%0.5% or ash%>20% or K%>0.5% in the garbage components, the computer control system receives the chemical element analysis The signal detected by the instrument sends an instruction to the high-pressure air compressor, opens the air source and the high-pressure air valve, and pushes the garbage on the belt conveyor to the impurity garbage collection box; when the chemical element analyzer detects that the garbage When C%>55% and H%>6% in the composition, the computer control system receives the signal detected by the chemical element analyzer, sends instructions to the high-pressure air compressor, open...

specific Embodiment 2

[0039] Such as Figure 4 As shown, the garbage is subjected to pretreatment such as bag breaking, crushing and screening, and the pretreated garbage mixture is placed on the belt conveyor, and the online real-time detection chemical element analyzer located above the belt conveyor is used to analyze the garbage. Detection and analysis, when the chemical element analyzer detects C%Cl%>0.5% or ash%>20% or K%>0.5% in the garbage components, the computer control system receives the The signal detected by the chemical element analyzer sends an instruction to the high-pressure air compressor, opens the air source and the high-pressure air valve, and pushes the garbage on the belt conveyor to the garbage collection box for impurities, which is harmless for the garbage of impurities. chemical treatment; when the chemical element analyzer detects that C%>30% and Cl%>50% in the garbage composition, the computer control system receives the signal detected by the chemical element analyzer...

specific Embodiment 3

[0040] Such as Figure 5As shown, the garbage is subjected to pretreatment such as bag breaking, crushing and screening, and the pretreated garbage mixture is placed on the belt conveyor, and the online real-time detection chemical element analyzer located above the belt conveyor is used to analyze the garbage. Detection and analysis, when the chemical element analyzer detects C%0.5% or ash%>20% or K%>0.5% in the garbage components, the computer control system receives the chemical element analysis The signal detected by the instrument sends an instruction to the high-pressure air compressor, opens the air source and the high-pressure air valve, and pushes the garbage on the belt conveyor to the impurity garbage collection box; when the chemical element analyzer detects that the garbage When C%>55% and H%>6% and O%>30% in the composition, the computer control system receives the signal detected by the chemical element analyzer, sends instructions to the high-pressure air compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com