High-efficiency aerobic fermentation device of organic wastes

An organic waste and aerobic fermentation technology, which is applied in the field of urban organic waste treatment, can solve the problems of hindering the popularization and application of aerobic fermentation technology, the product cannot be reduced in quantity, the degree of mechanization is not high, and the area is small. , The effect of short fermentation period and saving reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

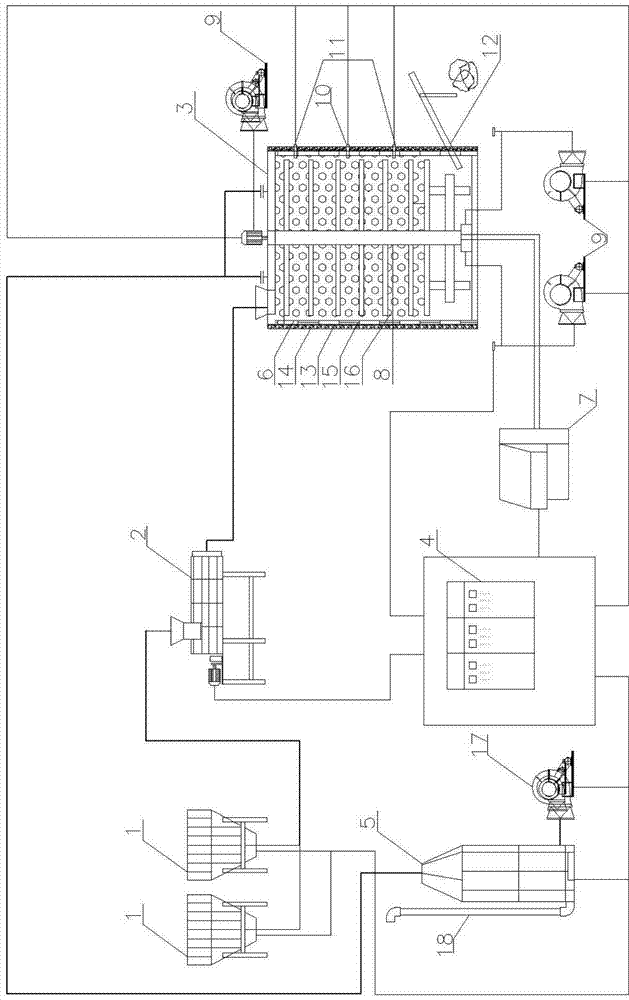

[0023] Example: such as figure 1 As shown, a high-efficiency aerobic fermentation device for organic waste includes a storage bin 1, a material crushing and mixing equipment 2, a fermentation reaction bin 3, an exhaust gas treatment device 5 and a PLC controller 4; Shaped or rectangular bin body, the top is equipped with a material inlet, and the bottom is equipped with a material outlet. The material inlet is large and the material outlet is conical. The material outlet of the storage bin 1 is crushed and mixed with the material through a belt and a pump. The feed port of the equipment 2 is connected, and the material is transported to the material mixing equipment 2 for subsequent processing. The material crushing and mixing equipment 2 of this embodiment uses a biaxial shearing crusher to crush the waste to the required size, and at the same time make the material fully The degree of mixing and crushing shall be adjusted according to the actual design requirements; the disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com