Machining process of copper pipe for ultrathin-walled air conditioner

A process flow and technology of copper tubes, which are applied in the field of processing process of copper tubes for ultra-thin-walled air conditioners, can solve the problems of further improvement in the thinning of copper tubes, and achieve excellent processing processes, good surface quality, The effect of high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and example the present invention will be further described:

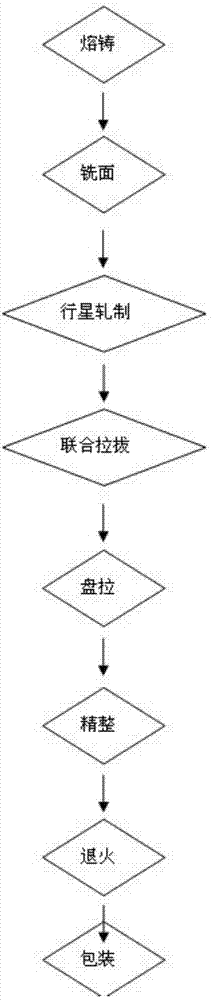

[0016] like figure 1 Shown, a kind of processing technological flow of ultra-thin-wall air-conditioning copper tube, it is characterized in that, the steps of described processing technological flow are as follows:

[0017] a) Melting and casting: Add high-purity cathode copper plates with a raw material of more than 99.95% into the casting furnace, rely on high-frequency electromagnetic heating to melt the copper plates, keep charcoal covering during the casting process, and add phosphor copper according to the ratio; carry out continuous casting, and the casting temperature is 1075± At 5°C, a copper tube blank of Φ90×8000mm was prepared;

[0018] b) Face milling: mill the oxide skin on the surface of the copper tube billet with a milling cutter;

[0019] c) Rolling: Put the Φ90×8000mm copper tube blank into the core head, push it into the three-roll planetar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com