Determination method for rare earth oxide in rare earth concentrate

A rare earth oxide and rare earth concentrate technology, applied in the field of metallurgical analysis, can solve the problems of X-ray fluorescence spectrometry interference, high detection cost, poor correction effect, etc., and achieve the effect of saving medicine, short operation process and reducing detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

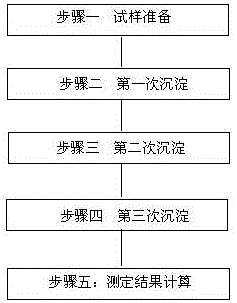

[0030] The specific embodiment of the present invention is described below in conjunction with accompanying drawing:

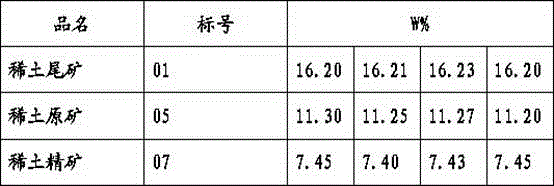

[0031] The method steps of this specific embodiment are as figure 1 As shown, select three kinds of samples, namely rare earth tailings, marked as 01, rare earth raw ore, marked as 05, and rare earth concentrate marked as 07, and each sample was carried out in 4 groups of comparative experiments according to the following methods, specifically The method is:

[0032] Weigh 0.5000 g of the sample and place it in a corundum crucible filled with 1-2 grams of sodium hydroxide to remove water, add 2-3 grams of sodium peroxide, mix well, and cover the surface with a layer of sodium peroxide. Melt in a muffle furnace at 700°C for 10 minutes, take out the crucible from the muffle furnace, and cool it down. After cooling, put it into a 400mL beaker filled with 150mL triethanolamine (1+10) and boil for leaching, wash the crucible with water, heat and boil the solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com