Method for preparing metal copper by electrolytic refining

A technology of electrolytic refining and metal copper, which is applied to the improvement of process efficiency, instruments, optics, etc., can solve the problems of high copper content, environmental pollution, high impurity content, etc., and achieve short operation process, low energy consumption, and environmental friendliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0047] (1) 5mol of choline chloride is mixed with 5mol of ethylene glycol to obtain a low co-solvent, and 0.05mol / L of copper chloride is added, and after mixing, an electrolyte is prepared;

[0048] (2) the scrap copper that comprises 58% copper, 40.2% zinc, 0.5% lead, 0.5% nickel, 0.3% iron and 0.2% tin by mass fraction meter is used as anode, and pure copper sheet is used as cathode, through Enter direct current for electrolysis, control the electrolysis temperature to 42°C, and the current density to 100A / m 2 , and the cathode metal copper is obtained after electrolysis. The morphology of cathode metal copper is as follows Figure 4 shown. The product obtained from the cathode is copper powder, which has a small particle size and can form a flat and dense copper layer.

example 2

[0050] (1) The benzyltriethylammonium chloride of 5mol is mixed with the glycerol of 28mol to obtain a low co-solvent, and the cupric chloride of 0.1mol / L is added, and an electrolyte is prepared after mixing;

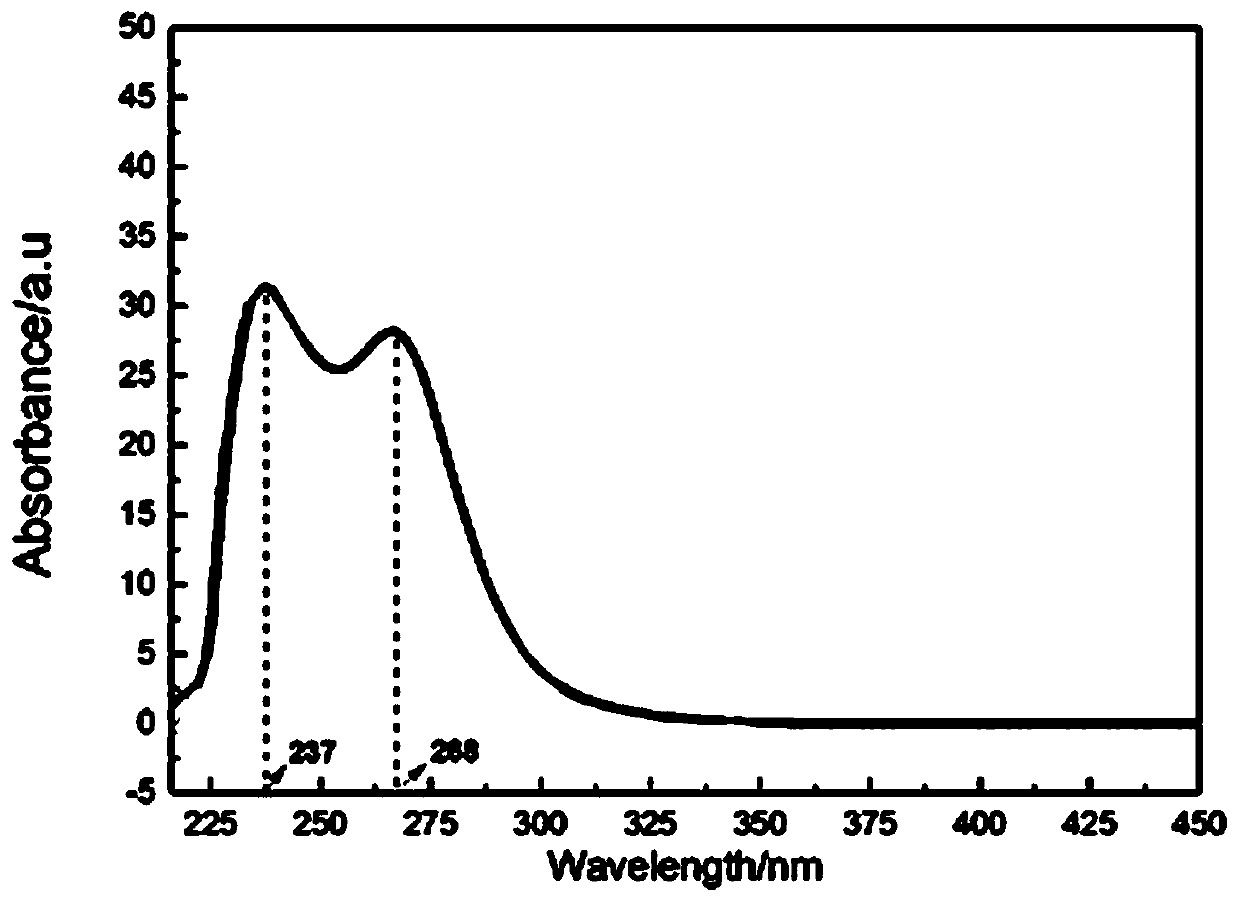

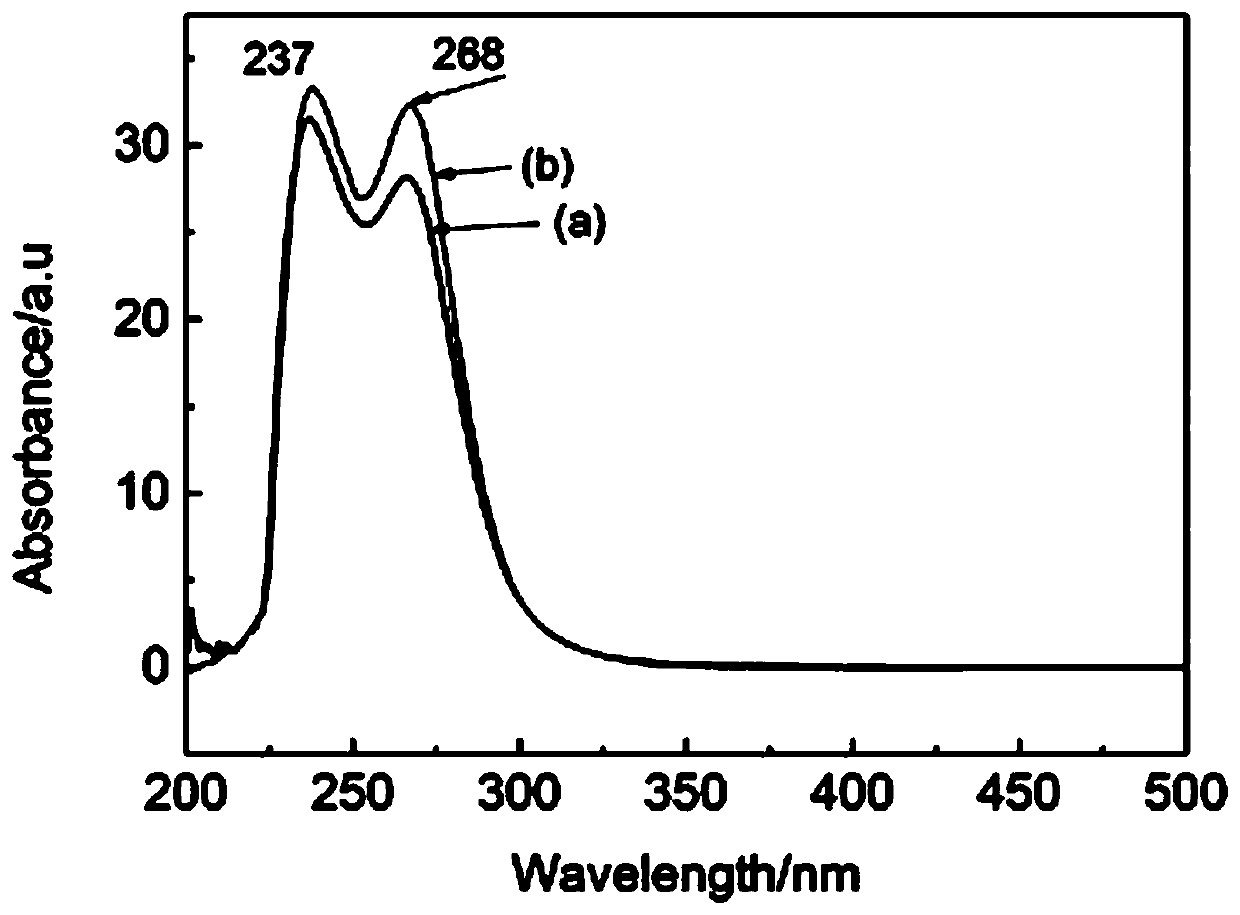

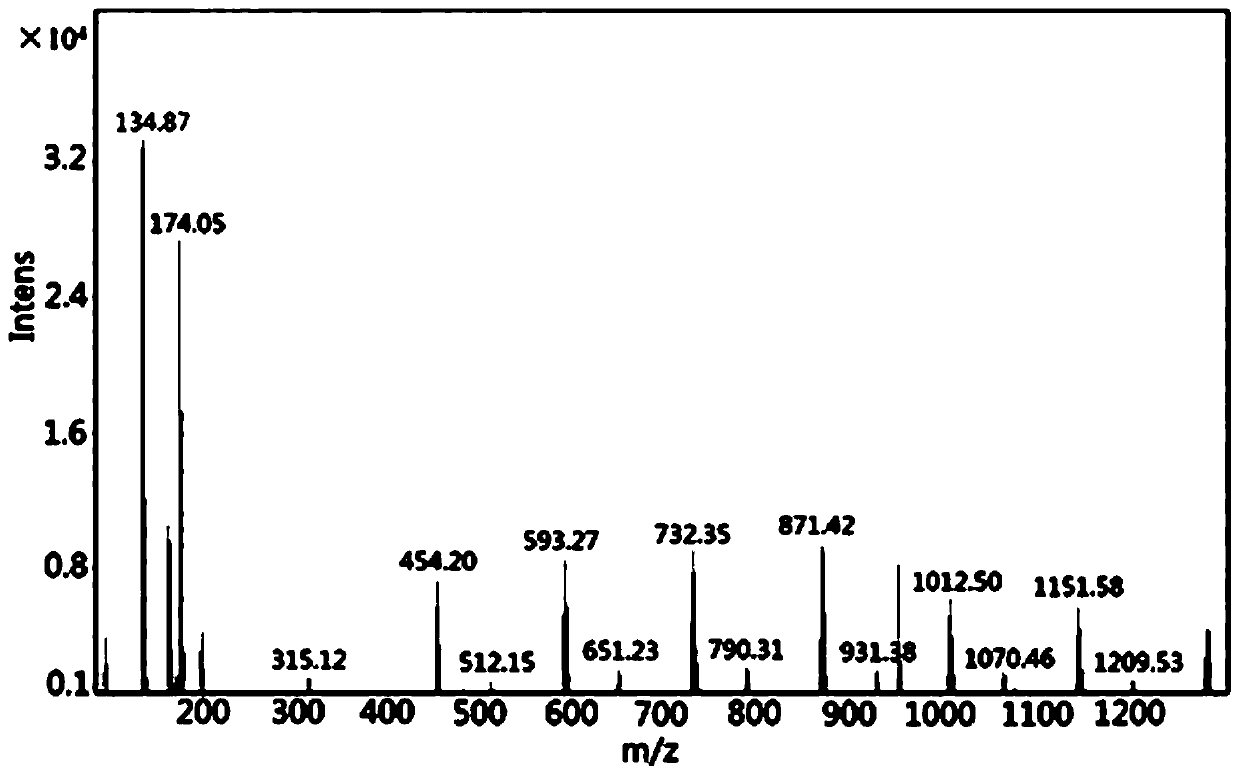

[0051] (2) the blister copper that comprises 99% copper, 0.02% zinc, 0.01% lead, 0.03% nickel and 0.01% tin by mass fraction meter is used as anode, and pure copper sheet is used as cathode, and feeds direct current and carries out electrolysis, Control the electrolysis temperature to 80°C and the current density to 200A / m 2 , and the cathode metal copper is obtained after electrolysis. Figure 5 with Image 6 are the XRD and SEM images of the obtained cathode metal copper, respectively. XRD shows that the obtained metallic copper is of high purity, and scanning electron microscopy shows that the product is copper powder with a small particle size and can form a flat and dense copper layer.

example 3

[0053] (1) The betaine hydrochloride of 5mol is mixed with the glycerol of 15mol to obtain a low co-solvent, and the cupric chloride of 0.02mol / L is added, and an electrolyte is prepared after mixing;

[0054] (2) the blister copper that mass fraction meter comprises 69% copper, 21% zinc, 3.6% lead, 2.7% nickel, 1.5% iron and 1.6% tin is as anode, pure copper sheet is as cathode, passes into Conduct electrolysis with direct current, control the electrolysis temperature to 62°C, and the current density to 50A / m 2 , and the cathode metal copper is obtained after electrolysis. The morphology of the obtained cathode metal copper is as follows Figure 7 As shown, the cathode metallic copper presents a dendritic feather.

[0055] In summary, the method of the present invention can realize the discharge of monovalent copper ions, can significantly reduce the energy consumption in the electrolytic refining process, and the method of the present invention has a short operation proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com