Intermittent micro-foaming injection molding equipment and intermittent micro-foaming injection molding process

An injection molding process and injection molding technology, applied in intermittent micro-foaming injection molding equipment and process, micro-foaming injection molding equipment and process fields, can solve the problems of high control difficulty, large control uncertainty, large investment cost, etc. , to achieve the effect of reducing complexity, reducing impact and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention, and further describe the technical solution of the present invention in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

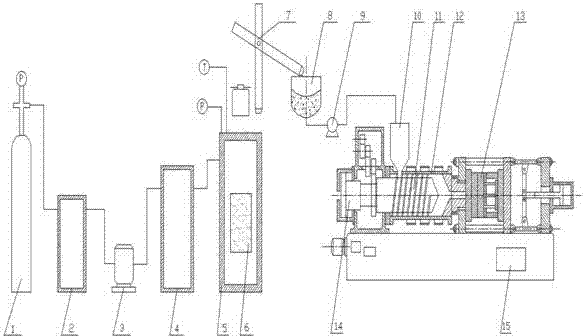

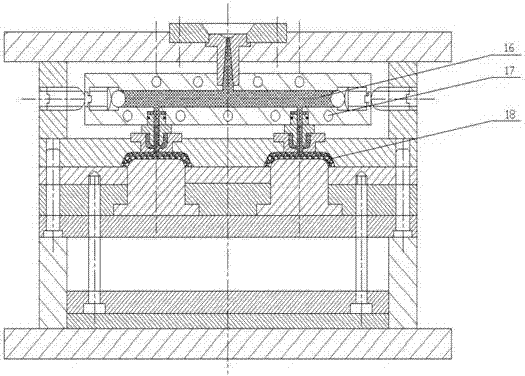

[0027] Such as figure 1 As shown, the micro-foaming injection molding equipment of the present invention mainly includes a supercritical fluid permeation system, a material storage system and an injection molding system.

[0028] In the solution of the present invention, the gas storage bottle 1, the condenser 2, the booster pump 3, the preheating circulator 4 and the osmosis kettle 5 can be connected flexibly with stainless steel corrugated hoses or rigidly connected with metal pipes, otherwise specified exception. The inlet and outlet of gas cylinder 1, condenser 2, booster pump 3, preheating circulator 4 and permeation kettle 5 can all be metal pipes, unless otherwise specified.

[0029] The supercritical fluid permeation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com