Preparation method of Cr-doped CaTiO3 yellow ceramic pigment, products prepared by using preparation method and applications

A ceramic pigment, yellow technology, applied in the field of ceramic pigments, can solve the problems such as no relevant reports, and achieve the effect of simple process route, stable performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

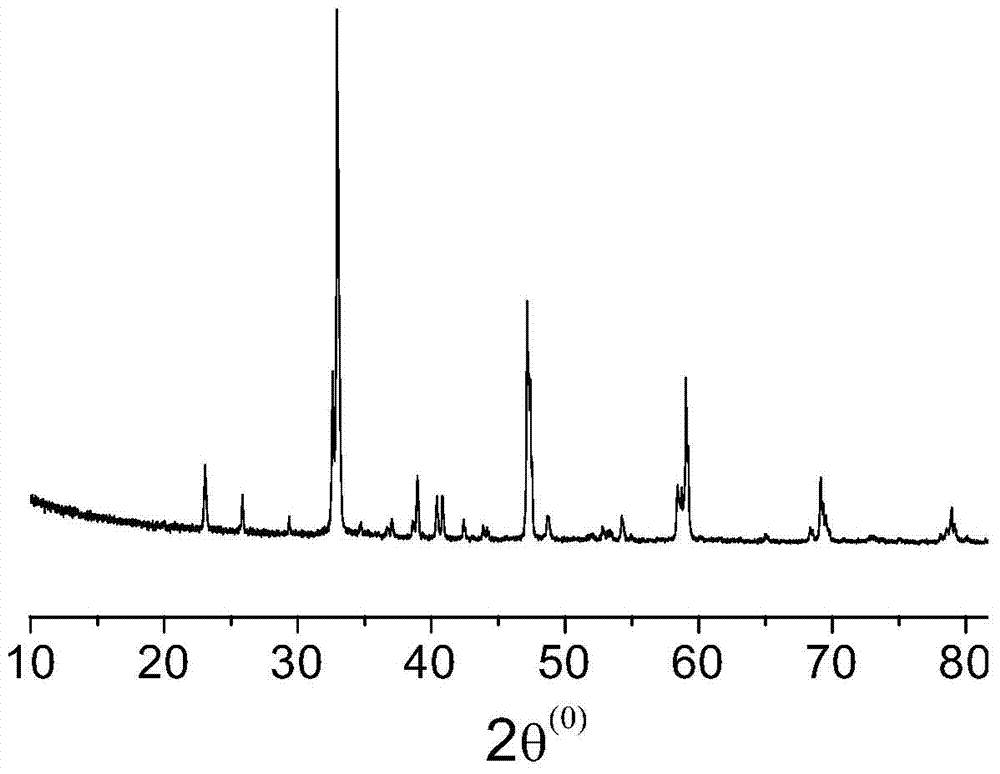

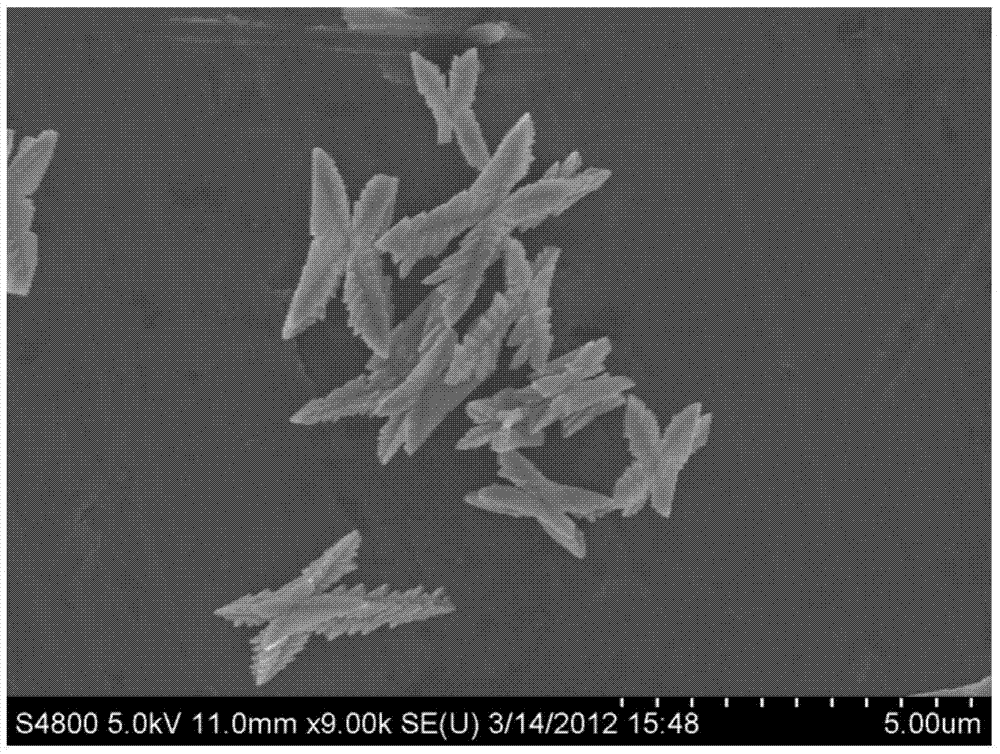

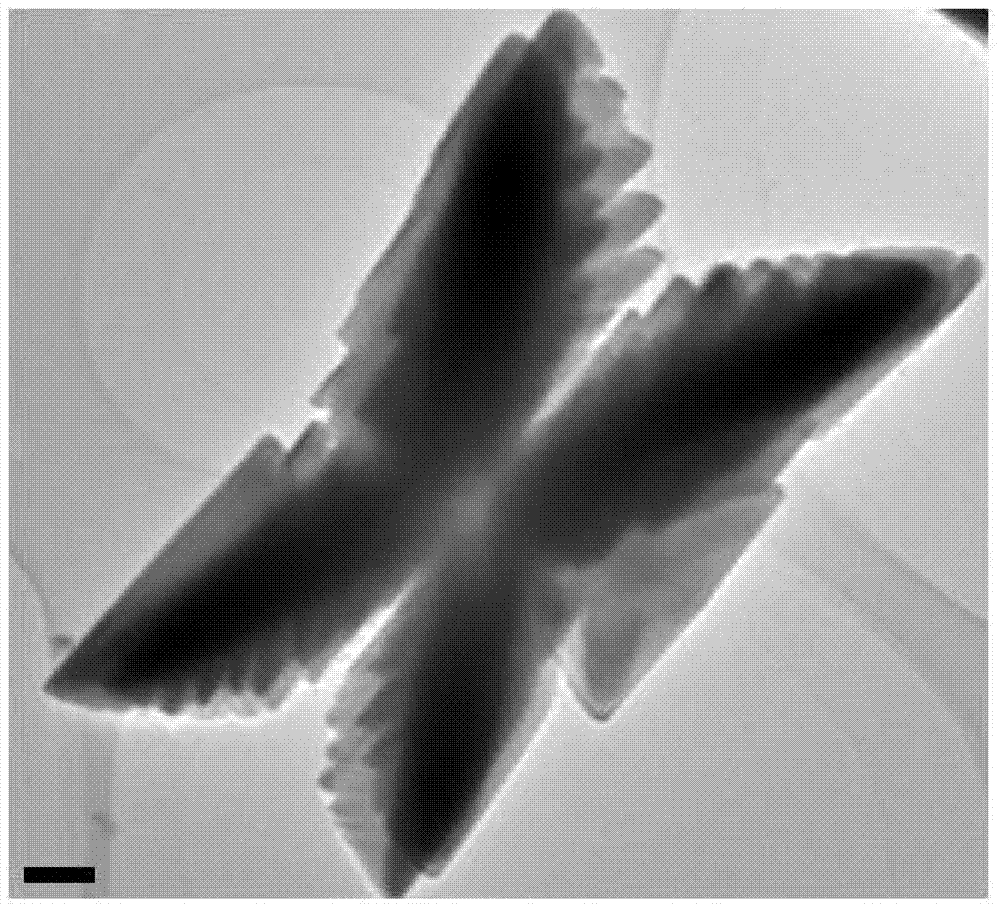

[0020] 1. A kind of CaTiO doped with Cr in this embodiment 3 The preparation method of yellow ceramic pigment, its step is as follows:

[0021] (1) According to the molar ratio of butyl titanate: ethanol = 1: 10, dissolve butyl titanate in ethanol, stir until uniform to obtain liquid A;

[0022] (2) Calcium chloride dihydrate and chromium nitrate are dissolved in distilled water, mixed with ethanol, and stirred evenly to obtain liquid B; wherein, according to the molar ratio of calcium chloride dihydrate: distilled water: ethanol=1: 400: 5, nitric acid The doping amount of chromium is 0.01% according to the molar percentage;

[0023] (3) According to the molar ratio of calcium chloride dihydrate: butyl titanate = 1: 1, drop liquid A into liquid B and stir and mix for 10 minutes, then gradually add NaOH solution dropwise, so that the pH of the mixed solution system = 12 , continue to stir for 15 minutes, put it in a hydrothermal kettle, and keep it at a temperature of 180 ° C...

Embodiment 2

[0028] 1. A kind of CaTiO doped with Cr in this embodiment 3 The preparation method of yellow ceramic pigment, its step is as follows:

[0029] (1) According to the molar ratio of butyl titanate:ethanol=1:5, dissolve butyl titanate in ethanol, stir until uniform to obtain liquid A;

[0030] (2) Calcium chloride dihydrate and chromium nitrate are dissolved in distilled water, mixed with ethanol, and stirred evenly to obtain liquid B; wherein, according to the molar ratio of calcium chloride dihydrate: distilled water: ethanol=1: 200: 10, nitric acid The doping amount of chromium is 0.05% according to the molar percentage;

[0031] (3) According to the molar ratio of calcium chloride dihydrate: butyl titanate = 1: 1, drop liquid A into liquid B and stir and mix for 5 minutes, then gradually add NaOH solution dropwise to make the pH of the mixed solution system = 12 , continue to stir for 15 minutes, put it in a hydrothermal kettle, and keep it at a temperature of 220 ° C for 2...

Embodiment 3

[0034] 1. A kind of CaTiO doped with Cr in this embodiment 3 The preparation method of yellow ceramic pigment, its step is as follows:

[0035] (1) According to the molar ratio of butyl titanate: ethanol = 1:8, dissolve butyl titanate in ethanol, stir until uniform to obtain liquid A;

[0036] (2) Calcium chloride dihydrate and chromium nitrate are dissolved in distilled water, mixed with ethanol, and stirred evenly to obtain liquid B; wherein, according to the molar ratio of calcium chloride dihydrate: distilled water: ethanol=1: 150: 5, nitric acid The doping amount of chromium is 0.07% according to the molar percentage;

[0037] (3) According to the molar ratio of calcium chloride dihydrate: butyl titanate = 1: 1, drop liquid A into liquid B and stir and mix for 5 minutes, then gradually add NaOH solution dropwise to make the pH of the mixed solution system = 12 , continue to stir for 15 minutes, put it in a hydrothermal kettle, and keep it at a temperature of 260 ° C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com