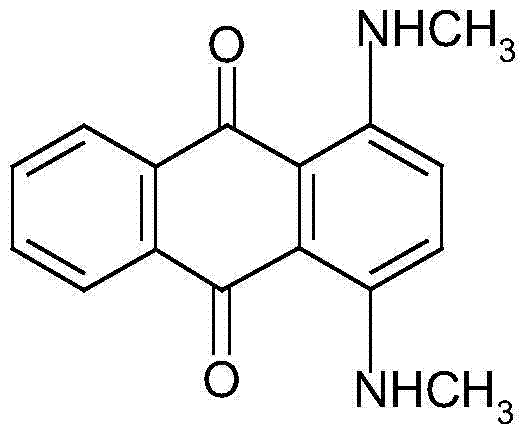

Method for preparing solvent blue 78

A technology of solvent and monomethylamine, which is applied in the field of organic chemical synthesis, can solve the problems of low product yield, large amount of waste water, high water content, etc., and achieve the effects of increased yield, reduced waste water, and low water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

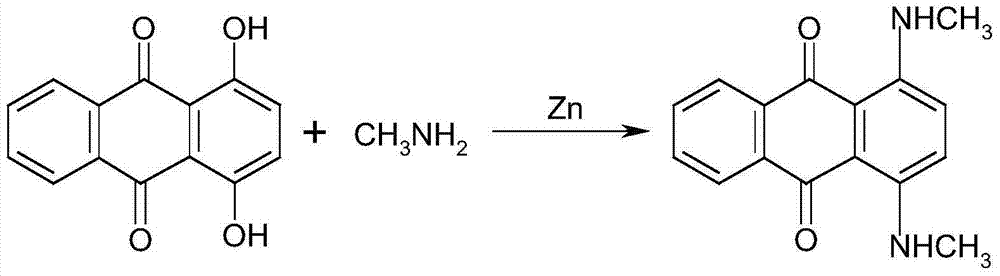

Method used

Image

Examples

Embodiment 1

[0015] Put 400g of 5w% liquid caustic soda into the reactor, then add 40g of 1,4-dihydroxyanthraquinone, 3g of hydrosulfite, 17.2g of monomethylamine, close the reaction system, start to heat up to 70°C, keep it warm for 12h, and the reaction is over , start to filter, wash until the filtrate is clear, dry, and weigh. After HPLC detection, the purity of the finished product is 95%, and the yield is 92%. After inspection, the color light and intensity are all qualified.

Embodiment 2

[0017] Put 400g of 6.5w% liquid caustic soda into the reactor, then add 40g of 1,4-dihydroxyanthraquinone, 3g of hydrosulfite, 17.2g of monomethylamine, close the reaction system, start to heat up to 70°C, keep warm for 12h, and react At the end, start to filter, wash until the filtrate is clear, dry, and weigh. After HPLC detection, the purity of the finished product is 96%, and the yield is 90%. After inspection, the color light and intensity are all qualified.

Embodiment 3

[0019] Put 400g of 8w% liquid caustic soda into the reactor, then add 40g of 1,4-dihydroxyanthraquinone, 3g of hydrosulfite, 17.2g of monomethylamine, close the reaction system, start to heat up to 70°C, keep it warm for 12h, and the reaction is over , start to filter, wash until the filtrate is clear, dry, and weigh. After HPLC detection, the purity of the finished product is 96%, and the yield is 88%. After inspection, the color light and intensity are all qualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com