Magnesium-doped metal-organic frame DMMg0.5Co0.5F single-crystal material and preparation method thereof

An organic framework, single crystal material technology, applied in organic chemistry and other directions, can solve the problem of unreported preparation methods of single crystal materials, and achieve the effects of easy operation, high product purity, and strong process controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

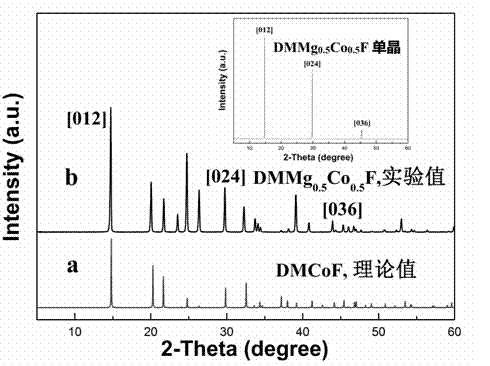

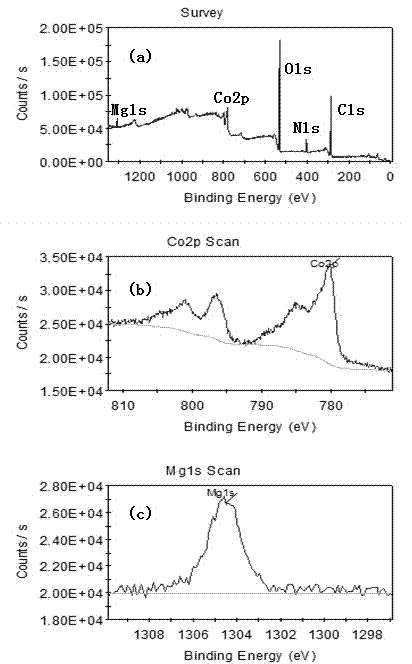

[0025] Weigh 2.5 mmol of magnesium chloride and cobalt chloride according to the molar ratio of 1:1, dissolve them in 15 mL of distilled water with 15 mL of N,N-dimethylformamide (DMF), and stir to fully dissolve; DMF and distilled water The volume ratio is 1:1. This mixed solution is packed in the reactor, and it is heated to 140 ℃ to react after sealing, and is incubated 60 hours, then naturally cools to room temperature. Take out the saturated supernatant after reaction with a pipette and put it into the beaker cleaned in step (1), and then put the beaker into a constant temperature and humidity chamber; set a 30-stage cooling curve, and the temperature range is 28-22° C, the temperature difference of each section is 0.5°C, and the temperature interval of each section is kept warm for 2.5 hours, and the humidity is 50%. The crystal particles at the bottom of the beaker were washed 3 times with absolute ethanol, and dried under vacuum at 60°C for 10 minutes to obtain transp...

Embodiment 2

[0028] As in Example 1, weigh 2.5 mmol of magnesium chloride and cobalt chloride according to the molar ratio of 1:1, dissolve them in 15 mL of distilled water with 15 mL of N,N-dimethylformamide (DMF), stir to fully dissolve ; The volume ratio of DMF to distilled water is 1:1. This mixed solution is packed in the reactor, and it is heated to 140 ℃ to react after sealing, and is incubated 65 hours, then naturally cools to room temperature. Take out the saturated clear liquid after reaction with a pipette and put it into the beaker cleaned in step (1), and then put the beaker into a constant temperature and humidity chamber; set a 30-stage cooling curve, and the temperature range is 28-22° C, the temperature difference of each section is 0.5°C, and the temperature interval of each section is kept warm for 3 hours, and the humidity is 45%. The crystal particles at the bottom of the beaker were washed 3 times with absolute ethanol, and dried under vacuum at 60°C for 10 minutes t...

Embodiment 3

[0030] As in Example 1, weigh 2.5 mmol of magnesium chloride and cobalt chloride according to the molar ratio of 1:1, dissolve them in 15 mL of distilled water with 15 mL of N,N-dimethylformamide (DMF), stir to fully dissolve ; The volume ratio of DMF to distilled water is 1:1. This mixed solution is packed in the reactor, and it is heated to 135 ℃ to react after sealing, and is incubated 65 hours, then naturally cools to room temperature. Take out the saturated clear liquid after reaction with a pipette and put it into the beaker cleaned in step (1), and then put the beaker into a constant temperature and humidity chamber; set a 30-stage cooling curve, and the temperature range is 28-22° C, the temperature difference of each section is 0.5°C, and the temperature interval of each section is kept warm for 2.5 hours, and the humidity is 45%. The crystal particles at the bottom of the beaker were washed 3 times with absolute ethanol, and dried under vacuum at 60°C for 10 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com