Polymerized organic silicon flame-retardant charring agent polymer and preparation method thereof

A technology of organosilicon and char-forming agent, applied to polymeric organosilicon flame-retardant char-forming agent polymer and preparation thereof, silicon-based flame-retardant char-forming agent polydimethyl silicate resorcinol ester polymer and its preparation In the field of preparation, it can solve the problems of poor processing performance, low decomposition temperature, easy water absorption, etc., and achieve the effects of excellent flame retardant effect, low volatility and large molecular weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

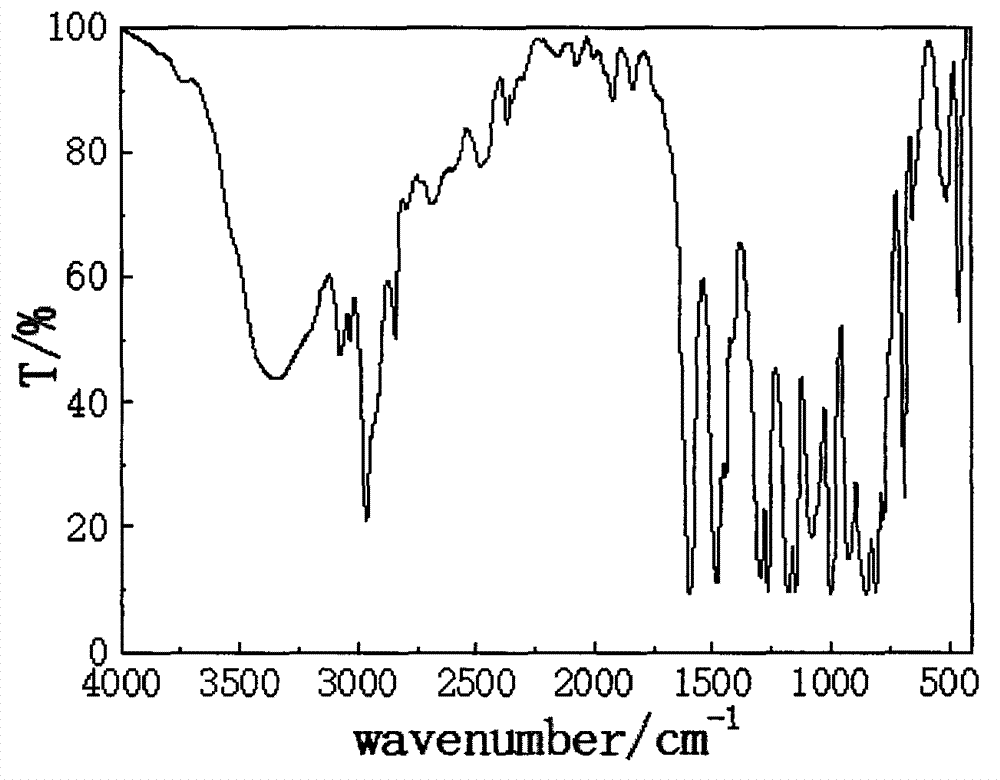

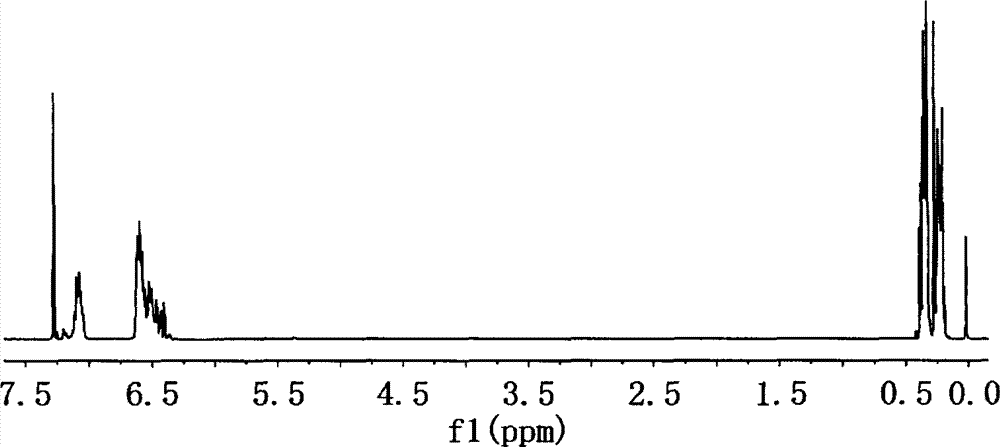

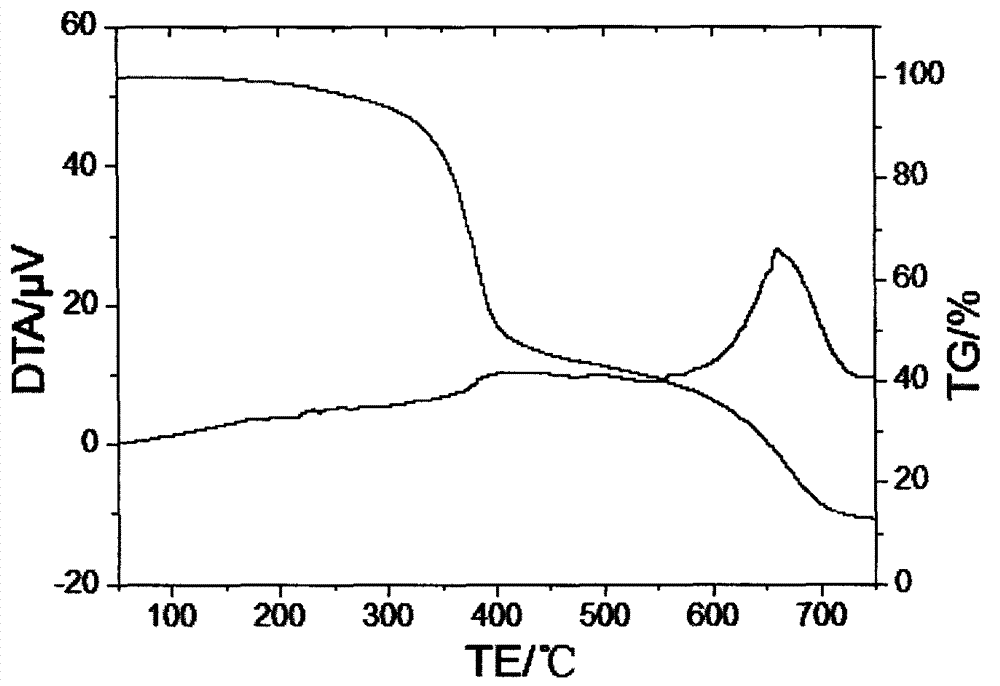

[0040]Example 1 In a 250ml four-necked bottle equipped with a stirrer, a thermometer and a condensing tube, and a drying tube at the top of the condensing tube, replace the air in the bottle with nitrogen, and add 5.50 g (0.05 mol) of resorcinol Phenol, 110ml dichloroethane and 10.1g (0.1mol) triethylamine, dropwise add 6.45g (0.05mol) dimethyldichlorosilane, control the reaction temperature with the rate of addition not higher than 30 ℃, be warmed up to 65°C, heat preservation reaction for 10 hours, then dropwise add 0.04g of methanol as an end-capping agent, heat preservation reaction for 0.5h; lower the temperature to below 30°C, then add 30ml of distilled water to wash twice, separate the liquid, and wash the obtained dichloroethane layer with 6g Dry over anhydrous sodium sulfate, filter, and distill off the filtrate under reduced pressure to remove dichloroethane to obtain resorcinol polydimethylsilicate with a yield of 92.8%.

Embodiment 2

[0041] Example 2 In a 250ml four-necked bottle equipped with a stirrer, a thermometer and a condenser tube, and a drying tube on the top of the condenser tube, the air in the bottle was replaced with nitrogen, and 5.50g (0.05mol) of benzenediol was added. Phenol, 80ml toluene and 11.11g (0.11mol) triethylamine, add dropwise 6.45g (0.05mol) dimethyldichlorosilane, control the reaction temperature with the rate of addition not higher than 30°C, and raise the temperature to 70°C after dropping, Insulate and react for 7 hours, then add 0.05g of methanol dropwise as an end-capping agent, and insulate for 0.5h; lower the temperature to below 30°C, then add 30ml of distilled water to wash twice, separate the layers, and dry the obtained toluene layer with 7g of anhydrous magnesium sulfate , filtered, and the filtrate was distilled off toluene under reduced pressure to obtain resorcinol polydimethylsilicate. Yield: 93.9%, weight average molecular weight: 8314, number average molecular...

Embodiment 3

[0042] Example 3 In a 250ml four-necked bottle equipped with a stirrer, a thermometer and a condenser tube, and a drying tube on the top of the condenser tube, replace the air in the bottle with nitrogen, and add 5.50 g (0.05 mol) of m-phthalide Phenol, 90ml xylene and 11.11g (0.11mol) triethylamine, add dropwise 6.45g (0.05mol) dimethyldichlorosilane, control the reaction temperature with the dropping rate not higher than 30°C, and raise the temperature to 50°C after dropping , heat preservation reaction for 12 hours, then add 0.04g of methanol dropwise as an end-capping agent, heat preservation reaction for 0.5h; lower the temperature to below 30°C, then add 40ml of distilled water to wash twice, separate the liquid, and wash the obtained xylene layer with 9g of anhydrous sodium sulfate After drying and filtering, the filtrate was distilled off under reduced pressure to remove xylene to obtain resorcinol polydimethylsilicate with a yield of 92.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com