Alizarin red pH response color-changing fibers and preparation method thereof

A color-changing fiber and alizarin red technology, applied in the field of material processing, can solve problems such as uneven impregnation, short-term effect, and poor washability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

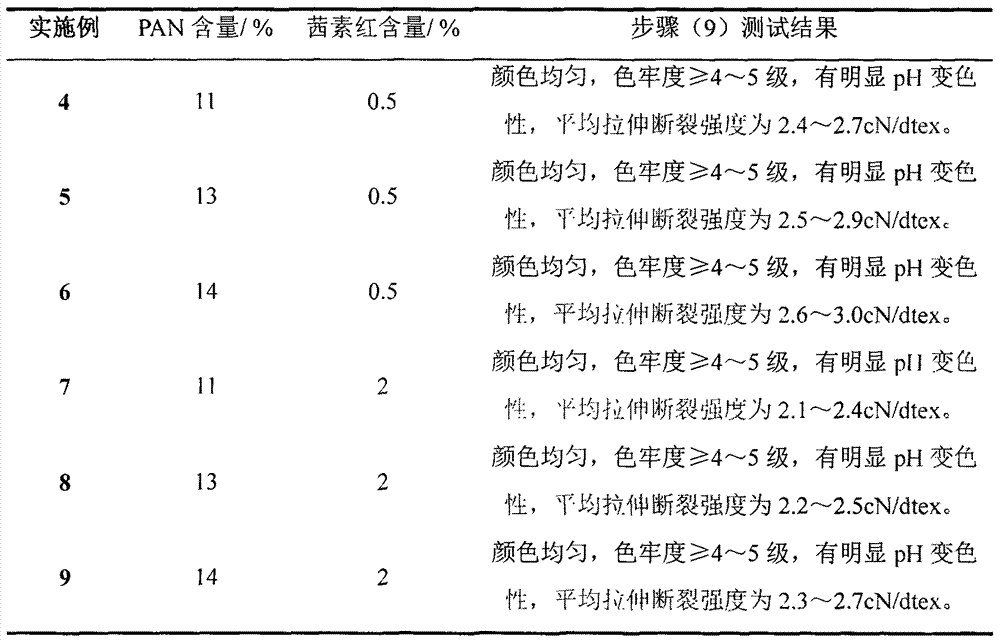

Examples

Embodiment 1

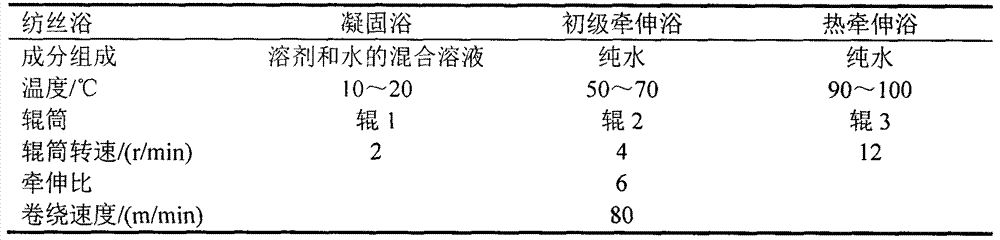

[0038] The spinning steps are:

[0039] (1) PAN powder is dried and dehydrated, and separated by sieve filtration.

[0040] A certain amount of PAN powder is placed in an oven, and dried by a staged heating method, (60°C×1h)→(80°C×1h)→(100°C×2h)→(105°C×1h).

[0041] Use a 100-150 mesh stainless steel mesh sieve to filter the dried PAN powder to remove large agglomerated particles. The sieved PAN fine powder was placed in a vacuum constant temperature oven at 40°C for later use.

[0042] (2) Selection of spinning solvent.

[0043] Considering many aspects such as rapid volatilization, skin-friendly safety, spinnability and solubility of alizarin red, 60% sodium thiocyanate (NaSCN) aqueous solution was selected as the spinning solvent, and 10% thiocyanate was used accordingly. Sodium aqueous solution is the coagulation bath.

[0044] (3) Determination of the content of PAN and Alizarin Red.

[0045] ① Prepare 100 g of spinning solution with a mass concentration of PAN of 12...

Embodiment 2

[0060] Step (1) PAN powder is dried and dehydrated, and separated by sieve filtration. Use the constant temperature drying method to dry at 100°C for 6 hours, and then use a 100-150 mesh stainless steel mesh sieve to filter and sieve to remove large agglomerated particles. The sieved PAN fine powder was placed in a vacuum constant temperature oven at 40°C for later use.

[0061] Steps (2)-(9) are the same as in Example 1.

Embodiment 3

[0063] The selection of step (2) solvent. Solvent uses 58% sodium thiocyanate (NaSCN) aqueous solution, method is the same as embodiment 1 in other steps.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com